Nissan Pathfinder. Instruction - part 410

DLN-82

< UNIT DISASSEMBLY AND ASSEMBLY >

[TRANSFER: TY21C]

RING GEAR SHAFT

Disassembly

INFOID:0000000009177780

1. Remove transfer cover assembly. Refer to

.

2. Remove ring gear bearing outer race (transfer cover side) and ring gear bearing adjusting shim (transfer

cover side) from the transfer cover. Refer to

.

3. Remove ring gear shaft assembly from the transfer case.

4. Remove ring gear bearing outer race (transfer case side) and ring gear bearing adjusting shim (transfer

case side) from the transfer case. Refer to

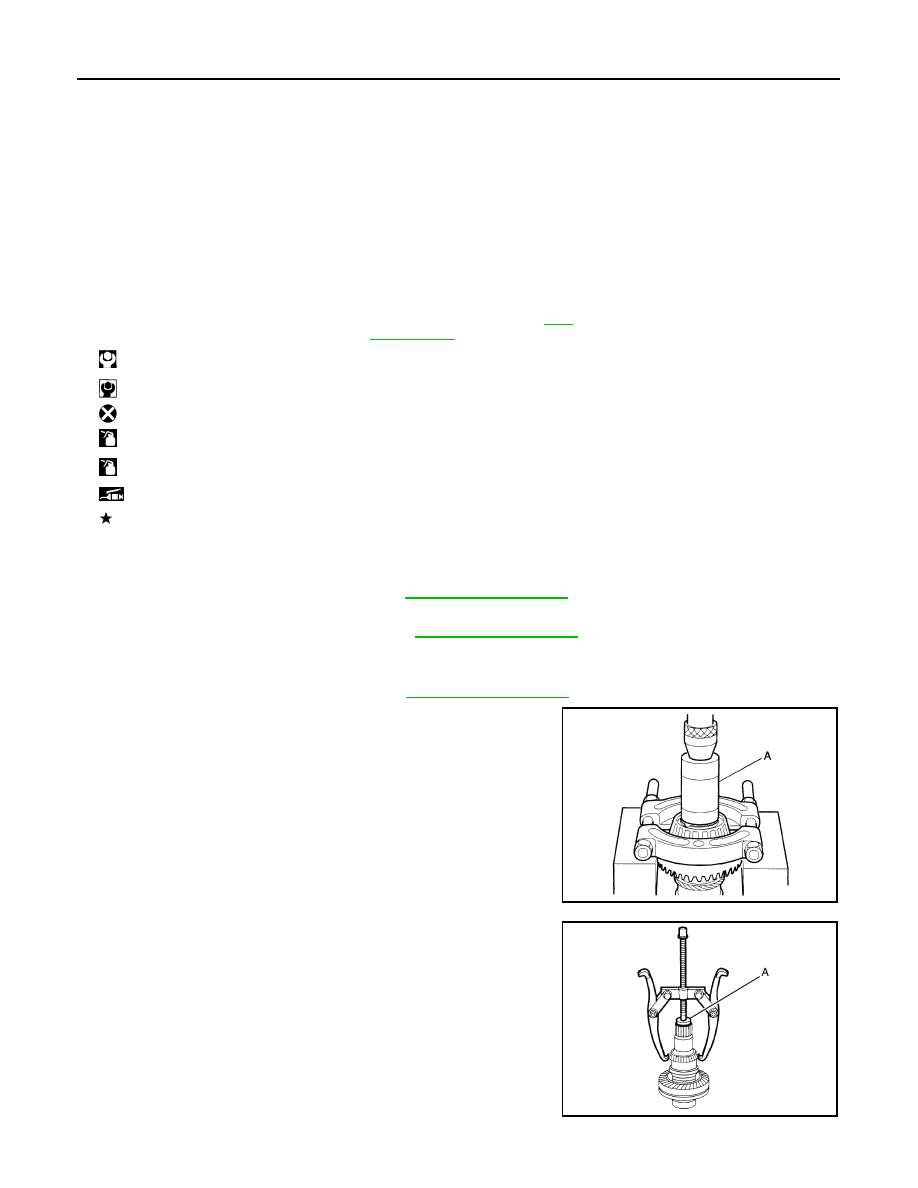

5. Remove ring gear bearing inner race (transfer cover side) from

ring gear shaft with drift (A) (commercial service tool) and

replacer (commercial service tool).

6. Remove ring gear bearing inner race (transfer case side) from

ring gear shaft with the drift (A) [SST: ST33061000 (J-8107-2)]

and puller (commercial service tool).

7. Remove the ring gear mounting bolts.

7.

O-ring

8.

Ring gear bearing adjusting shim

(transfer cover side)

9.

Ring gear bearing (transfer cover

side)

10. Drive shaft oil seal

11. Ring gear shaft

12. Ring gear bearing (transfer case

side)

13. Ring gear bearing adjusting shim

(transfer case side)

14. Ring gear

15. Baffle plate

16. Transfer case

17. Plug

18. O-ring

19. Oil seal

20. Dowel pin

21. Drive pinion

22. Drive pinion adjusting shim

23. O-ring

24. Pinion bearing assembly

25. Oil seal

26. Dust cover

27. Companion flange

28. Pinion lock nut

A. Oil seal lip

B. Comply with the assembly proce-

dure when tightening. Refer to

.

: N·m (kg-m, ft-lb)

: N·m (kg-m, in-lb)

: Always replace after every disassembly.

: Apply gear oil.

*

: Apply anti-corrosive oil.

: Apply multi-purpose grease.

: Select with proper thickness.

JPDIE0030ZZ

JPDIE0031ZZ