Isuzu N-Series. Service manual - part 874

7B1-20 MANUAL TRANSMISSION (MZZ)

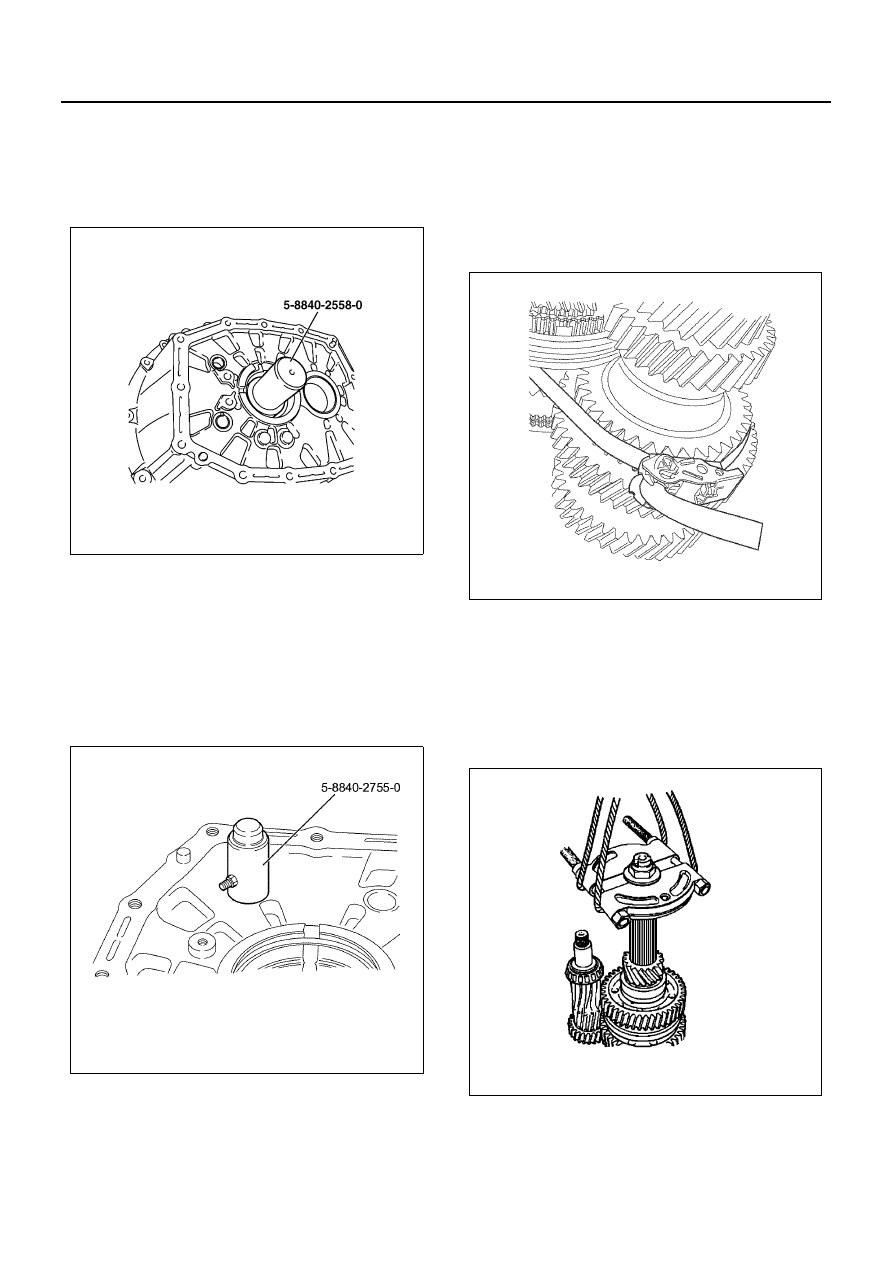

4. Use the installer (5-8840-2558-0) to press the oil

seal into the clutch housing.

Caution:

The lipped portion of the oil seal is easily broken. Exer-

cise care during the installation procedure.

5. Inspect the bearing outer race for wear and dam-

age. If wear or damage is present, the race must

be replaced.

6. Inspect the clutch housing bush for wear and dam-

age. If wear or damage is present, the bush must

be replaced.

7. Use the installer (5-8840-2755-0) to press the bush

into the clutch housing. Pay close attention to the

bush installation direction (refer to the illustration).

• Attach by crimping to secure at three points, but

avoid the grooved area and previous crimping

spots.

• Apply the second and subsequent bushing press-

es with the notch facing the clutch housing.

8. Attach the main shaft assembly, upper gear shaft

assembly, and countershaft assembly.

a. Tightly wrap belts such as lashing belts around

the main shaft assembly, countershaft assem-

bly, and upper gear shaft assembly at two or

more places to prevent the assemblies from

separating. Make sure that the upper gear shaft

does not fall when the assembly is suspended.

b. Secure the bearing remover to the main shaft

with a lock nut, then raise it with a hoisting ca-

ble. Spread the outer snap ring of the upper

gear shaft bearing, which is attached to the

clutch housing, and simultaneously install the

upper gear shaft assembly, main shaft assem-

bly, and countershaft assembly into the clutch

housing.

c. Set the outer snap ring of the upper gear shaft

bearing onto the clutch housing, spread it using

snap-ring pliers, and insert the upper gear shaft

bearing.

N7A0326E

N7A1104E

N7A1095E

N7A0356E