Isuzu N-Series. Service manual - part 690

6E-182 Engine Control System (4HK1)

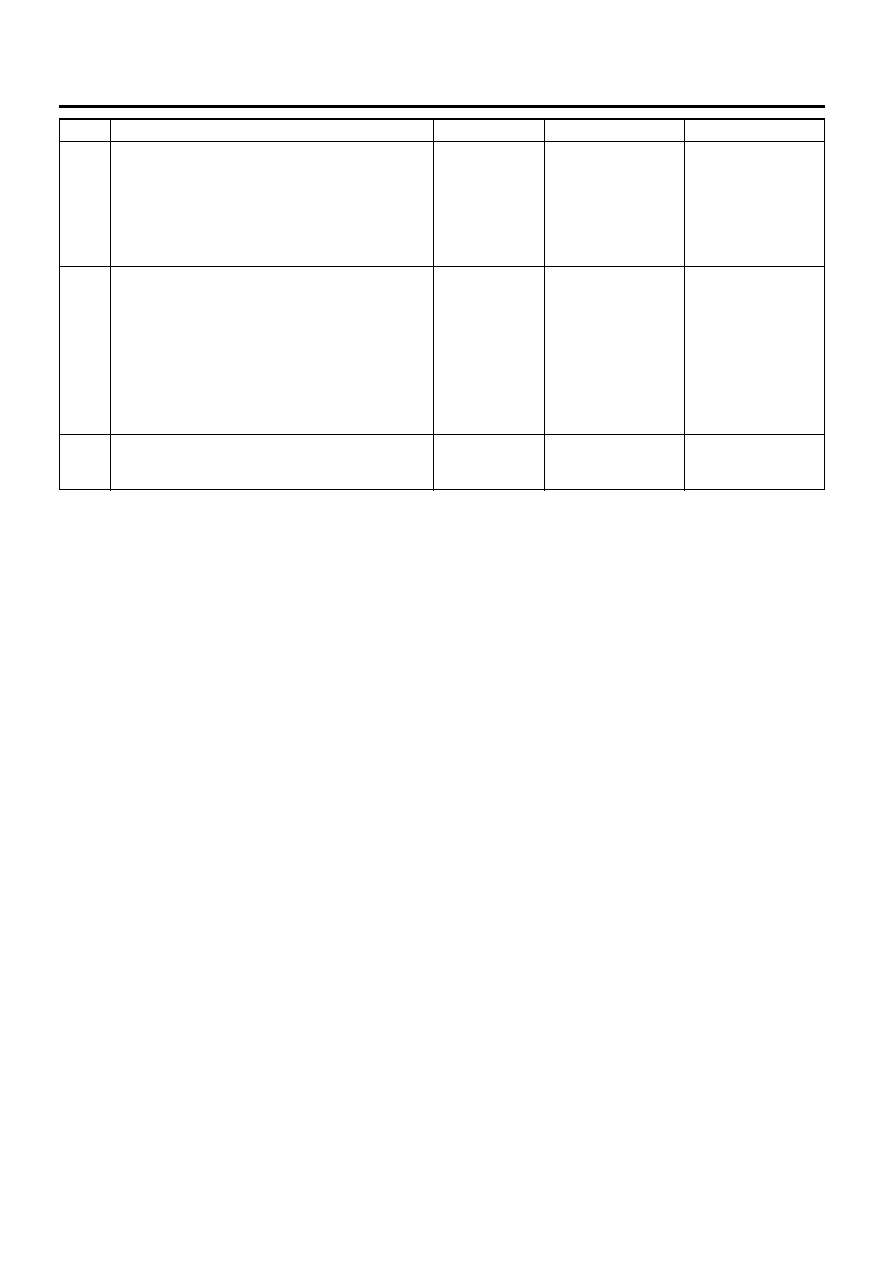

12

Important:

Replacement ECM must be programmed.

Replace the ECM. Refer to Engine Control Module

(ECM) Replacement / Fuel Injector ID Code Data

Programming in this section.

Did you complete the replacement?

—

Go to Step 13

—

13

1.

Reconnect all previously disconnected

harness connector(s).

2.

Clear the DTCs with the Tech 2.

3.

Turn OFF the ignition for 30 seconds.

4.

Start the engine.

5.

Operate the vehicle within the Conditions for

Running the DTC.

Did the DTC fail this ignition?

—

Go to Step 2

Go to Step 14

14

Observe the DTC Information with the Tech 2.

Are there any DTCs that you have not diagnosed?

—

Go to Diagnostic

Trouble Code (DTC)

List

System OK

Step

Action

Value(s)

Yes

No