Isuzu N-Series. Service manual - part 688

6E-174 Engine Control System (4HK1)

P0381 (Flash Code 67)

Circuit Description

The glow indicator lamp is located on the instrument

panel cluster (IPC). The glow control system is

operated when the engine coolant temperature is low,

which allows easier engine starting. If the ignition

switch is turned ON when the engine coolant

temperature is low, the engine control module (ECM)

illuminates the glow indicator lamp and turns ON the

glow plugs. After a fixed time passes, the ECM turns

OFF the glow indicator lamp and the glow plugs. The

ECM monitors the glow indicator lamp control circuit for

conditions that are incorrect for the commanded state

of the glow indicator lamp. For example, a failure

condition exists if the ECM detects low voltage when

the glow indicator lamp is commanded OFF, or high

voltage when the glow indicator lamp is commanded

ON. If the ECM detects an improper voltage on the

glow indicator control circuit, this DTC will set.

Condition for Running the DTC

• The ignition switch is ON.

• The ignition voltage is more than 18 volts.

Condition for Setting the DTC

Either of following condition is met:

• The ECM detects a low voltage condition on the

glow indicator lamp control circuit when the

indicator is commanded OFF for longer than 5

seconds.

• The ECM detects a high voltage condition on the

glow indicator lamp control circuit when the

indicator is commanded ON for longer than 5

seconds.

Action Taken When the DTC Sets

• The ECM does not illuminate the malfunction

indicator lamp (MIL) when the diagnostic runs and

fails.

Condition for Clearing the DTC

• A current DTC clears when the diagnostic runs and

does not fail at next driving cycle.

• A history DTC clears after 20 consecutive driving

cycles without a fault. Or clear with the Tech 2 or

accelerator pedal operation.

Diagnostic Aid

• If an intermittent condition is suspected, refer to

Intermittent Conditions in this section.

DTC P0381 (Flash Code 67)

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or Engine Control Module (ECM)

Connector End Views

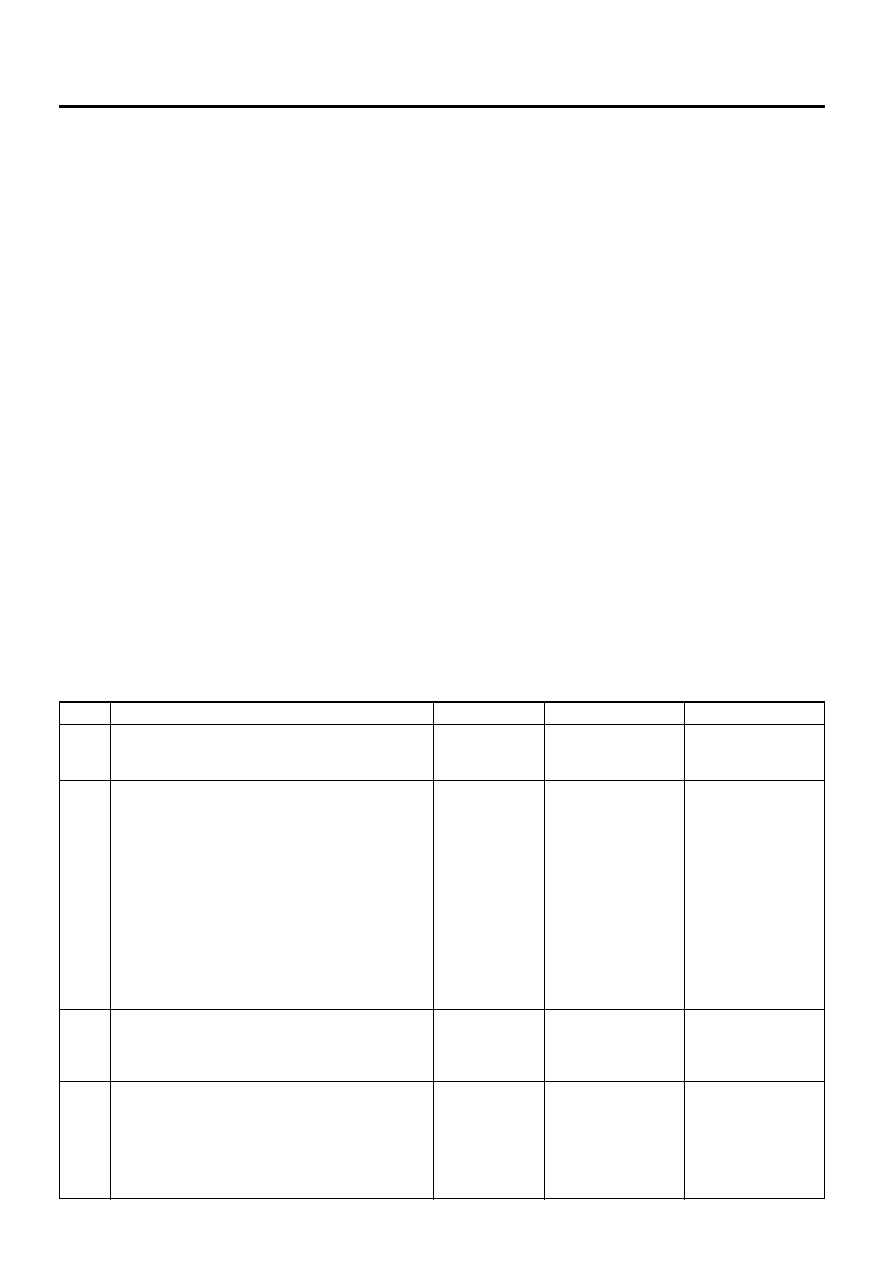

Step

Action

Value(s)

Yes

No

1

Did you perform the Diagnostic System Check –

Engine Controls?

—

Go to Step 2

Go to Diagnostic

System Check –

Engine Controls

2

1.

Verify whether the instrument cluster is

operational. If the instrument panel cluster

(IPC) is completely inoperative, refer to

Diagnostic System Check.

2.

Turn OFF the ignition for 30 seconds.

3.

Disconnect the engine coolant temperature

(ECT) sensor harness connector in order to

gain glow ON time long enough.

4.

Turn ON the ignition for 20 seconds while

observing the Diagnostic Trouble Code (DTC)

Information with the Tech 2.

Does the DTC fail this ignition?

—

Go to Step 3

Go to Diagnostic

Aids

3

1.

Turn OFF the ignition.

2.

Inspect the Meter (10A) fuse in the glove box.

Is the Meter (10A) fuse open?

—

Go to Step 4

Go to Step 5

4

Replace the Meter (10A) fuse. If the fuse continues

to open, repair the short to ground on one of the

circuits that is fed by the Meter (10A) fuse or

replace the shorted attached component fed by the

Meter (10A) fuse.

Did you complete the repair?

—

Go to Step 19

—