Isuzu N-Series. Service manual - part 607

6B-14 ENGINE COOLING

• Remove the radiator valve and check a negative

pressure valve as the center of the valve seat side.

If the negative pressure valve does not work

smoothly, clean or replace the radiator valve.

Tighten:

Radiator valve to 6 N

⋅m (0.6 kg⋅m/4 lb⋅ft)

• Conduct cooling system leakage check after rein-

stalling the radiator valve.

Radiator Core

• Deformed radiator fins could reduce radiation ef-

fects, resulting in overheat. Straighten the fins. In

such a case, take care not to damage the fin roots.

• Remove dust and other foreign materials.

Flushing the Radiator

• Wash the inside of radiator and the coolant pas-

sage with water and neutral detergent. Remove all

scales and rust.

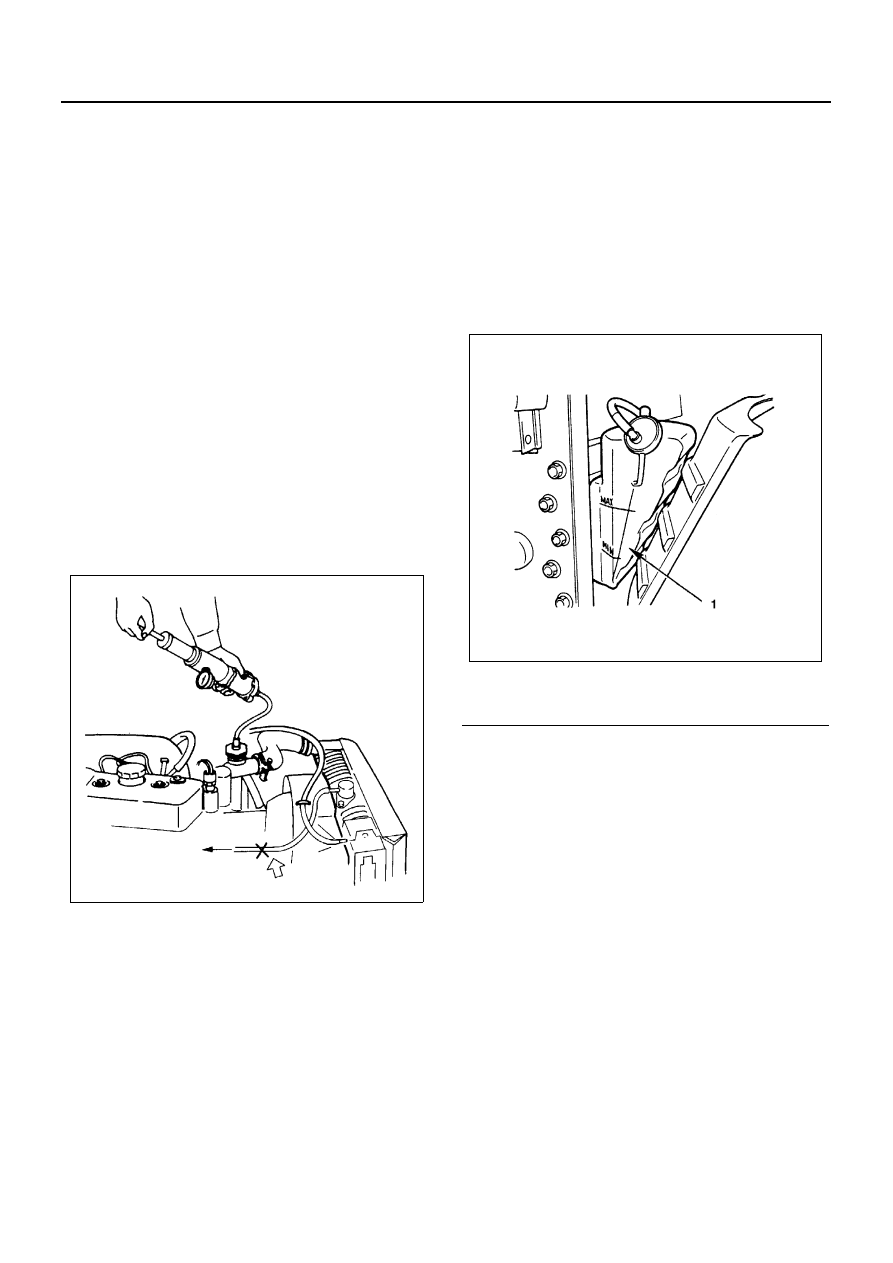

Checking for Coolant Leakage

• Clog up the reservoir tank hose carefully and check

the cooling system for leakage with a radiator cap

tester by applying an air pressure of 147 kPa (1.5

kg/cm

2

/21 psi) from filler neck to inside the radia-

tor.

• As the radiator upper tank is provided with a valve,

the pressure fails to rise higher than the valve

opening pressure unless the hose is clogged up.

Installation

1. Radiator Assembly

• Install the radiator.

2. Cushion Rubber

• Install cushion rubbers on both sides of radiator

bottom.

• Install radiator assembly with hose, taking care not

to damage the radiator core by a fan blade.

3. Condenser

4. Radiator Stay

5. Air Intake Duct

• Connect the duct and tighten clip securely.

6. Radiator Hose

• Connect inlet hose and outlet hose to the engine.

• Connect battery ground cable.

• Pour coolant up to filler neck of radiator, and up to

MAX mark of reservoir tank.

7. Reservoir Tank Hose & Bypass Hose

• Start engine to warm up, and check for coolant lev-

el.

N6A3389E

Legend

1. Reservoir tank

N6A3390E