Isuzu N-Series. Service manual - part 574

GENERAL ENGINE MECHANICAL 6A-53

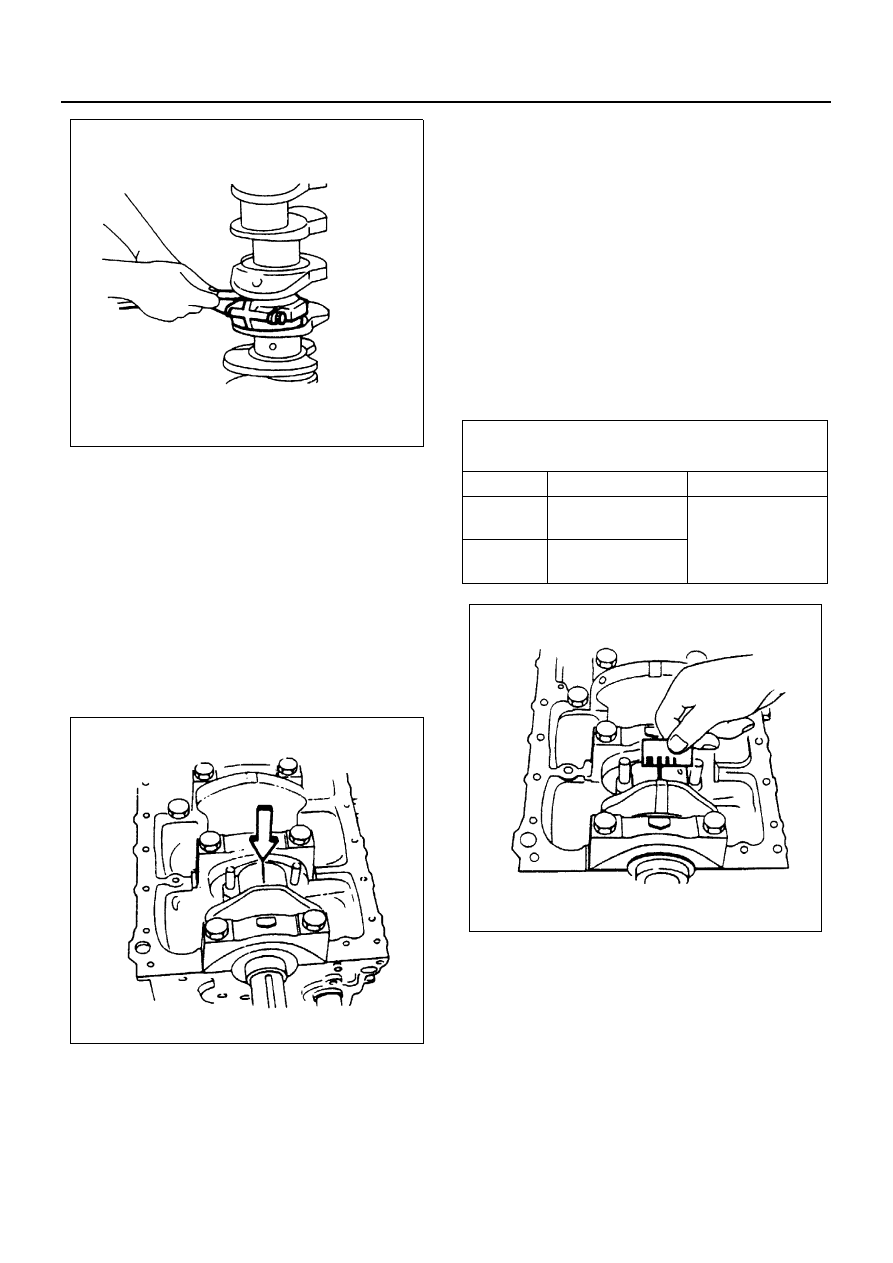

3. Measure the oil clearance between the connecting

rod and the crankshaft by:

1) Remove the connecting rod cap nuts and the

rod caps.

Arrange the removed rod caps in the cylinder

number order.

2) Clean the rod bearings and the crankshaft pins.

3) Carefully check the rod bearings.

If even one bearing is found to be damaged or

badly worn, the entire bearing assembly must

be replaced as a set. Reinstall the bearings in

their original positions.

Apply plastigage to the crank pin.

4) Put the plastigage, and reinstall the rod caps to

their original positions.

5) Tighten the cap nuts in 2 steps, using angular

tightening method as shown in the following

specifications. (4JG2, 4JH1-TC, 4JB1-TC)

Tighten:

• 4JH1-TC, 4JB1-TC to

1st Step: 29 N

⋅m (3 kg⋅m/22 lb⋅ft)

2nd Step: 45

° — 60°

• 4JB1 to 83 N

⋅m (8.5 kg⋅m/61 lb⋅ft)

Notice:

Do not allow the crankshaft to rotate.

6) Remove the rod caps.

7) Measure the width of the plastigage and deter-

mine the oil clearance. If the oil clearance ex-

ceeds the limit, replace the rod bearings as a

set.

8) Remove the plastigage from the bearings and

the crankshaft pins.

Reassembly

1. Connecting Rod

2. Piston

3. Piston Pin

Apply a cost of engine oil to the piston pin and the

piston pin hole.

N6A3184E

N6A3185E

Crankshaft Journal and Bearing Clearance

mm (in)

Standard

Limit

4JB1 /

4JB1-TC

0.029 — 0.066

(0.0011 — 0.0026)

0.100 (0.0039)

4JG2

4JH1-TC

0.029 — 0.083

(0.0011 — 0.0033

N6A3186E