Isuzu N-Series. Service manual - part 570

GENERAL ENGINE MECHANICAL 6A-37

4. Cylinder Block Rear Plate

Align the rear plate with the cylinder body knock

pins.

Tighten the rear plate to the specified torque

Tighten:

82 N

⋅m (8.4 kg⋅m/61 lb⋅ft)

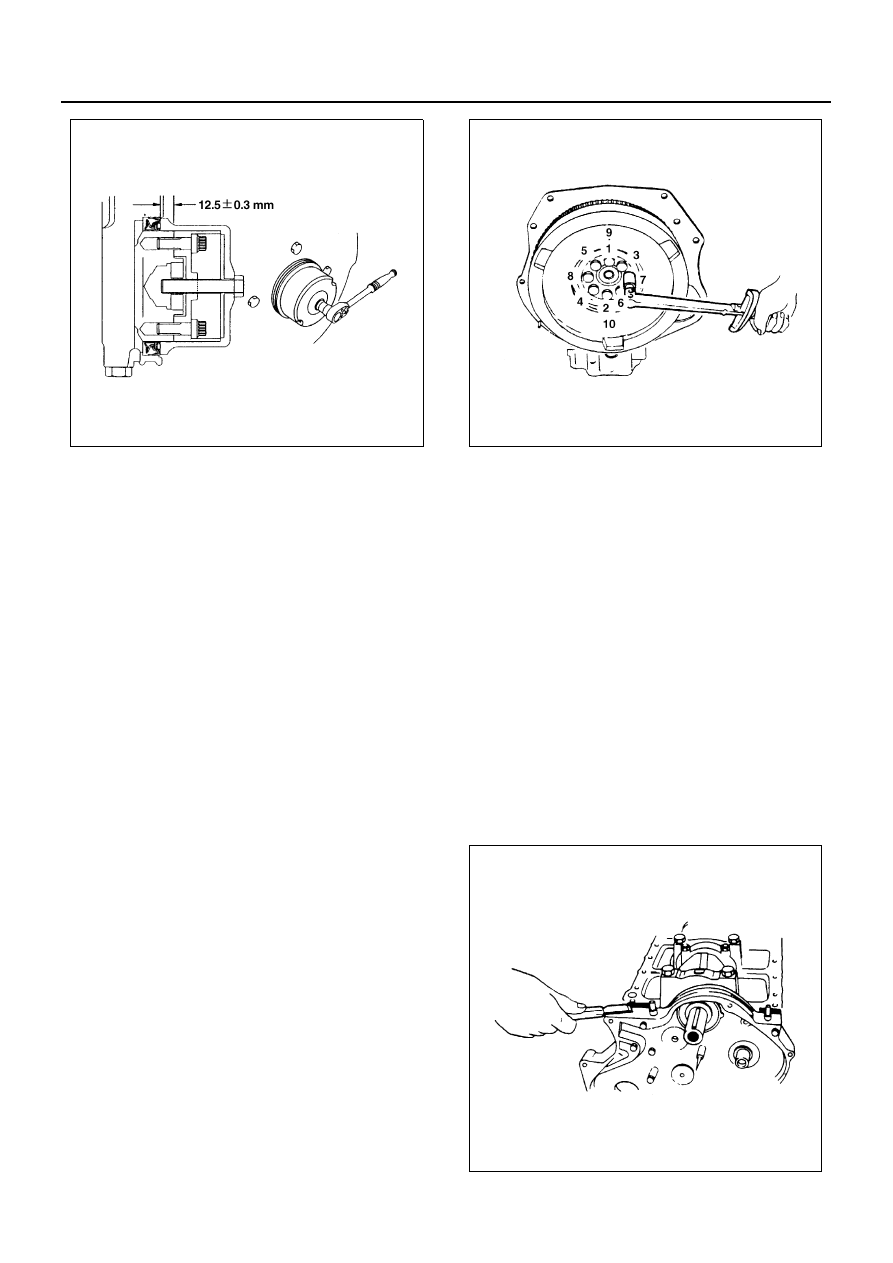

5. Flywheel

1) Thoroughly clean the remove the oil from the

threads of crankshaft.

2) Mount the flywheel on the crankshaft and then

install the washer.

3) Apply a coat of engine oil to the threads of the

flywheel bolts.

4) Align the flywheel with the crankshaft dowel

pin.

5) Tighten the flywheel bolts to the specified

torque in two steps using the Angular Tighten-

ing Method.

Follow the numerical order shown in the illus-

tration.

Tighten:

• Flywheel Bolt to

1st Step: 59 N

⋅m (6.0 kg⋅m/43 lb⋅ft)

2nd Step: 60

° — 90°

6. Piston and Connecting Rod

7. Piston Cooling Oil Pipe

8. Oil Pump Assembly

Above works refer to “PISTON AND CONNECT-

ING ROD”

Section in this manual.

9. Timing Pulley Housing

1) Install the timing pulley housing to the cylinder

body.

Notice:

Take care not to twist the front oil seal.

2) Tighten the timing pulley housing bolt together

with the timing pulley housing gasket to the

specified torque.

Tighten:

19 N

⋅m (1.9 kg⋅m/14 lb⋅ft)

3) Cut away the gasket protruding above the fit-

ting surfaces (as shown in the illustration).

10. Timing Gear Housing

N6A3145E

N6A3112E

N6A3146E