Isuzu N-Series. Service manual - part 522

Cooling System 6B-19

Radiator core

1. If the radiator fin is deformed, the radiation effect

deteriorates causing overheating. Therefore,

modify the fin. Make sure that the root base of the

fin is not damaged during modification.

• Eliminate dust or other foreign matter.

Washing the radiator

1. Wash the internal parts of the radiator and cooling

water passage using water and detergent.

Eliminate scale and rust completely.

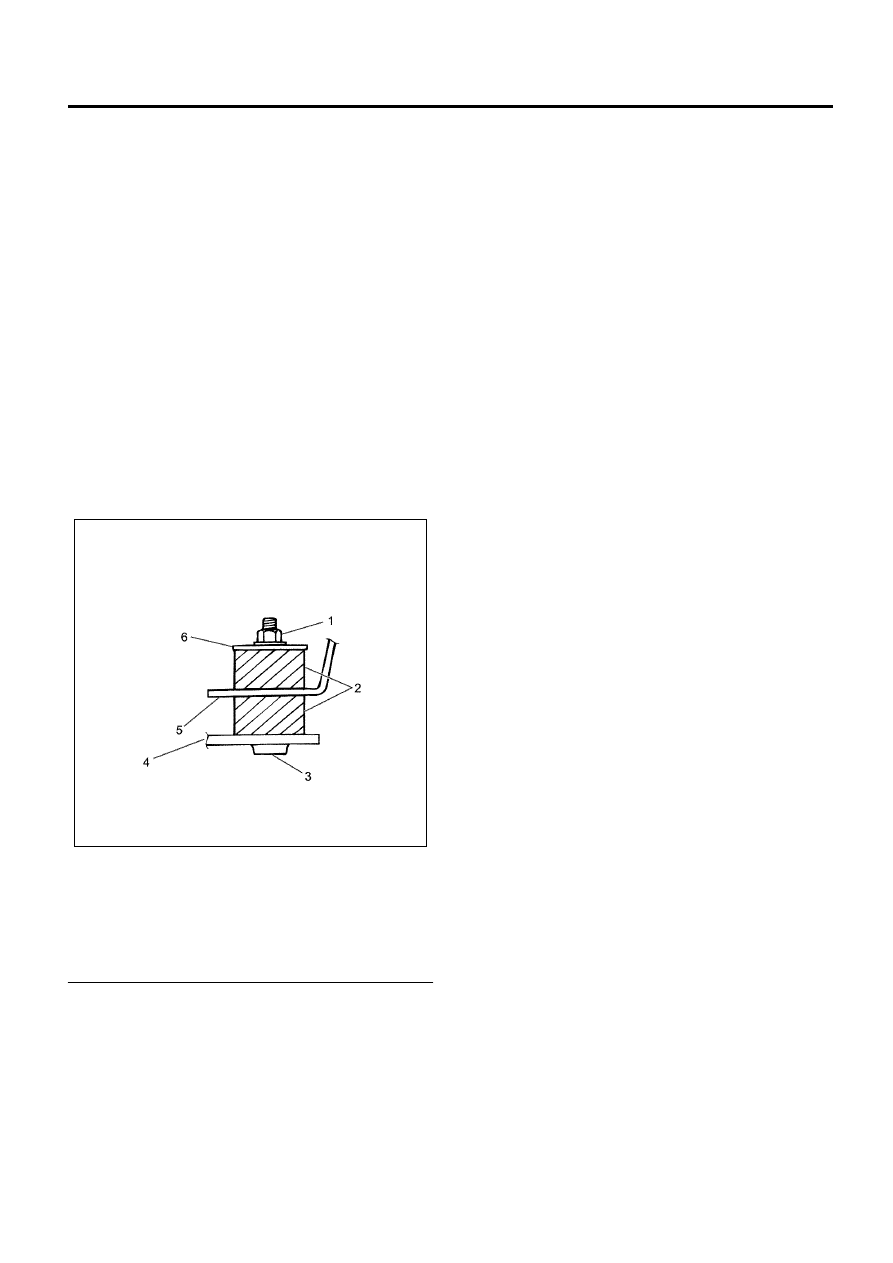

Installation

1. Ensure that no damage occurs to the radiator core

because of the fan blade. Mount the brackets on

the left and right sides of the radiator on the frame

according to the figure.

Tighten:

Bolts to 55 N

⋅m (5.6 kg⋅m / 41 lb⋅ft)

Legend

1. Flange Nut

2. Rubber

3. Stud Bolt

4. Frame

5. Bracket on The Radiator Side

6. Washer

2. Mount the reserve tank hose of the coolant on the

radiator.

3. Mount the radiator lower hose.

4. Mount the radiator upper hose.

• Fill the cooling water.

5. Install the 2 transmission oil pipes on the

underside of the radiator.

6. Install the intake pipe from the turbocharger and

inter-cooler (left side).

7. Install the intake pipe from the intake manifold and

inter-cooler (right side).

Reference

Cooling water injection procedure (in case of changing

the cooling water completely)

• Confirm that the engine has cooled.

• Open the radiator cap and the reserve tank cap.

• Pour the cooling water up to the filler neck.

• Pour the cooling water up to the “MAX” line in the

reserve tank.

• Close the radiator cap and the reserve tank cap

and start the engine. Stop the engine after running

for about 2 to 3 minutes at the idling rpm. Open the

radiator cap again and replenish if the water level

is low.

WARNING:

DO NOT LOOSEN OR REMOVE THE RADIATOR

CAP WHEN THE TEMPERATURE OF THE COOLING

WATER IS HIGH. STEAM OR BOILING WATER WILL

GUSH OUT AND YOU MAY BE BURNT. TO OPEN

THE RADIATOR CAP, COVER THE CAP WITH A

THICK CLOTH WHEN THE COOLING WATER IS

COOL, RELEASE THE PRESSURE BY SLOWLY

TURNING THE CAP, AND THEN REMOVE THE CAP.

• After tightening the radiator cap, warm up the

engine by running it at about 2000 rpm. Also,

adjust the temperature of the heater to maximum

temperature and circulate the cooling water even

in the heater water conduit system.

• When the pointer of the thermometer crosses the

median and the thermostat has activated, run at

idling rpm for another 5 minutes, then stop the

engine and leave it as-is.

• After the engine has cooled down sufficiently,

check the water level in the filler neck part and

replenish if necessary. If the level is extremely low,

check for leaks in the cooling water conduit system

and reserve tank hose.

N6A6247E