Content .. 1189 1190 1191 1192 ..

Isuzu N-Series. Service manual - part 1191

SRS CONTROL SYSTEM 9C-11

H-7

Procedure of Trouble Diagnosis

Diagnostic Trouble Code (Self-diagnosis Code)

At first, perform “SRS system check”. “SRS system

check” is to check whether “SRS” warning lamp oper-

ates properly and confirms SRS diagnostic trouble code

(DTC) using warning lamp blinking or Tech 2.

1. Active diagnostic trouble code: Function fault cur-

rently detected. Active diagnostic trouble codes

are stored in the RAM (Random Access Memory).

(Code of current trouble)

2. History diagnostic trouble code: Function fault de-

tected after history memory had been cleared last

time. History diagnostic trouble codes are stored in

the EEPROM. (Trouble code occurred in the past)

System Diagnostic Method

System diagnostic method is a standardized method to

repair all the electric/electronic (E/E) systems. Diagnos-

tic procedure is always used to solve the problem of E/

E system and is a starting point when service is re-

quired. Procedure of diagnosis is described in the fol-

lowing steps:

1. Confirm a customer’s complaint.

• It is necessary for technicians to understand the

normal operations of the systems to confirm a

customer’s complaint.

2. Perform pre-inspection.

• Perform overall visual check.

• Review service record.

• Detect noise or abnormal odor.

• Collect the diagnostic trouble code information

for effective repair.

3. Check service information.

• This includes video, news letter, etc.

If DTC is Stored

Perform service correctly according to the specified

DTC chart.

If there is No DTC

Select symptom from the diagnostic chart according to

symptom. Complete the service following diagnostic

procedure. You may also perform inspection by refer-

ring function diagnosis.

If there is No Applicable Symptom

1. Confirm the complaint in detail.

2. Create diagnostic plan.

3. Use wiring diagram and principle of operation.

Ask for technical support when repair history is available

for similar case. Connect technician’s knowledge with

the effective usage of available service information.

If there is Intermittent (Intermittent Trouble)

The trouble situation not occurring constantly is called

intermittent (intermittent trouble). Perform the following

steps to solve the intermittent trouble.

1. Check the DTC information and SRS data.

2. Evaluate symptom and situation explained by the

customer.

3. Check the circuits or the electric system compo-

nents using check sheet or other methods.

If the Trouble is not Detected

In this case, the vehicle is judged as it operates properly.

The condition explained by the customer may be the

normal condition. Confirm the customer’s complaint

comparing with the condition of the vehicle to that of an-

other vehicle. That condition may mean an intermittent

trouble. Confirm the complaint in the situation the cus-

tomer explains before returning the vehicle to the cus-

tomer.

1. Confirm the complaint again.

If the complaint can not be fully detected or identi-

fied, the vehicle must be diagnosed again. Confirm

the complaint one more time. The complaint may

be an intermittent trouble as defined in “If there is

intermittent”, but it may also be possible that the

vehicle is normal.

P-4

P-5

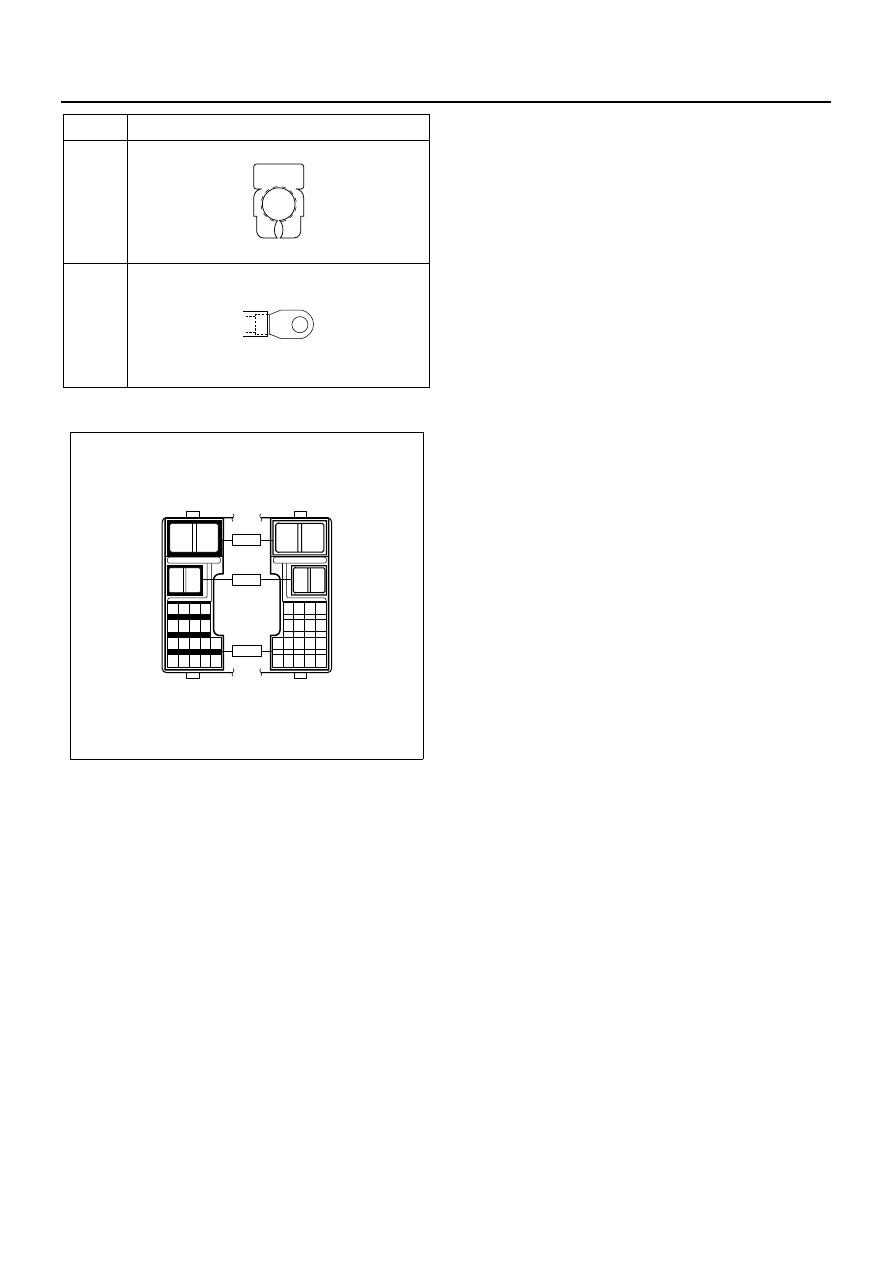

No.

Connector Face

000-004

000-002

1

2

1

2

1 2 3 4

5 6 7 8

9 10 11 12 13

14 15 16 17 18

2

1

2

1

4 3 2 1

8 7 6 5

13 12 11 10 9

18 17 16 15 14

H - 6

H - 7

H - 8

N8A5489E