Isuzu engine 4j series. Service manual - part 52

6A1 – 76 4JB1/4JB1T/4JB1TC/4JG2 - ENGINE

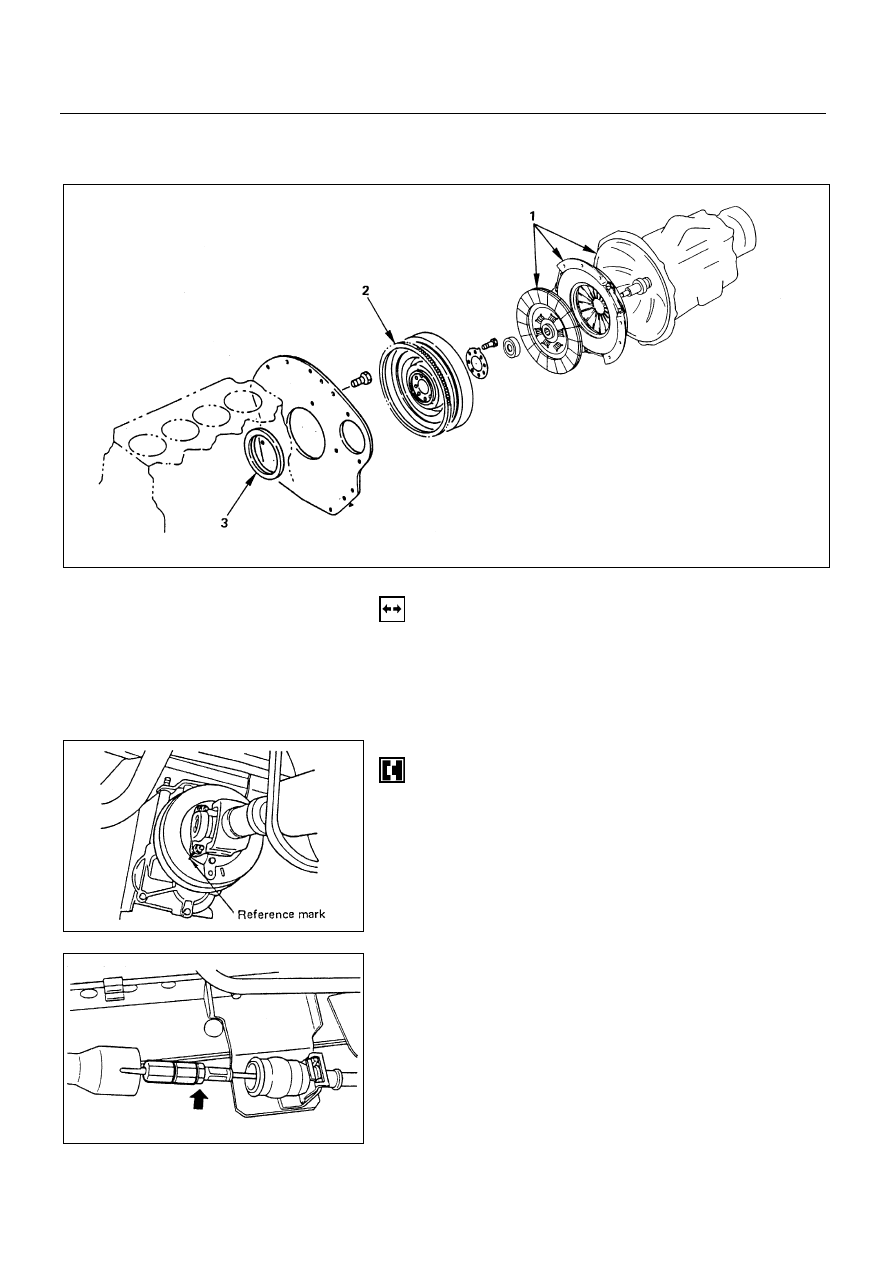

CRANKSHAFT REAR OIL SEAL (Gear & Belt Drive Type)

REMOVAL

Preparation:

•

Disconnect battery ground cable

1. Transmission and Clutch Assembly

•

Raise vehicle and support with suitable safely.

1) Transmission

!

Transmission

•

Reference mark the flange yoke to the parking brake

drum.

•

Disconnect the propeller shaft at flange yoke.

•

Put aside the propeller shaft and tie it to the frame so

that it does not interface with servicing work.

"

Parking Brake Cable

•

Move the joint cover.

•

Disconnect the joint bolt.

•

Remove the clip then disconnect the cable from the

bracket.

6A1-76-1.tif

6A1-76-2.tif

6A1-76-3.tif

Removal steps

1. Transmission and clutch Assembly

2. Flywheel

3. Rear oil seal

Installation steps

To install, follow the removal steps in the

reverse order.