Ford Mondeo (petrol engines). Manual - part 74

comb” or compressed air to clean the

condenser.

Warning: Wear eye protection

when using compressed air!

(d) Check that the drain tube from the front

of the evaporator is clear - note that it is

normal to have clear fluid (water) dripping

from this while the system is in operation,

to the extent that quite a large puddle can

be left under the vehicle when it is parked.

2 It’s a good idea to operate the system for

about 30 minutes at least once a month,

particularly during the winter. Long term

non-use can cause hardening, and

subsequent failure, of the seals.

3 Because of the complexity of the air

conditioning system and the special

equipment necessary to service it, in-depth

fault diagnosis and repairs are not included in

this manual. For more complete information

on the air conditioning system, refer to the

Haynes Automotive Heating and Air

Conditioning Manual.

4 The most common cause of poor cooling is

simply a low system refrigerant charge. If a

noticeable drop in cool air output occurs, the

following quick check will help you determine

if the refrigerant level is low.

5 Warm the engine up to normal operating

temperature.

6 Place the air conditioning temperature

selector at the coldest setting, and put the

blower at the highest setting. Open the doors

- to make sure the air conditioning system

doesn’t cycle off as soon as it cools the

passenger compartment.

7 With the compressor engaged - the clutch

will make an audible click, and the centre of

the clutch will rotate - feel the inlet and outlet

pipes at the compressor. One side should be

cold, and one hot. If there’s no perceptible

difference between the two pipes, there’s

something wrong with the compressor or the

system. It might be a low charge - it might be

something else. Take the vehicle to a dealer

service department or an automotive air

conditioning specialist.

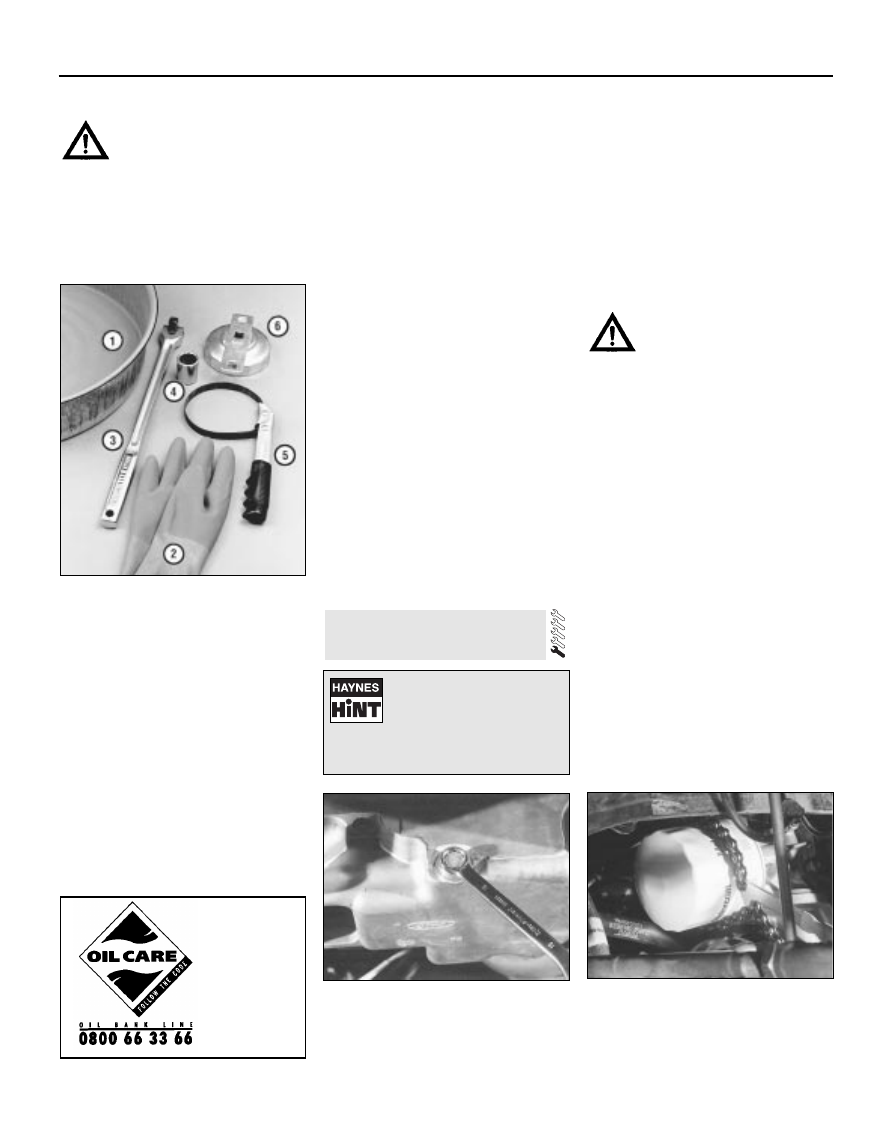

1 Make sure that you have all the necessary

tools before you begin this procedure (see

illustration). You should also have plenty of

rags or newspapers handy, for mopping up

any spills.

2 To avoid any possibility of scalding, and to

protect yourself from possible skin irritants

and other harmful contaminants in used

engine oils, it is advisable to wear gloves

when carrying out this work.

3 Access to the underside of the vehicle is

greatly improved if the vehicle can be lifted on

a hoist, driven onto ramps, or supported by

axle stands.

Warning: Do not work under a

vehicle which is supported only

by an hydraulic or scissors-type

jack, or by bricks, blocks of

wood, etc.

4 If this is your first oil change, get under the

vehicle and familiarise yourself with the

position of the engine oil drain plug, which is

located at the rear of the sump. The engine

and exhaust components will be warm during

the actual work, so try to anticipate any

potential problems while the engine and

accessories are cool.

5 The oil should preferably be changed when

the engine is still fully warmed-up to normal

operating temperature, just after a run (the

needle on the temperature gauge should be in

the “Normal” sector of the gauge); warm oil

and sludge will flow out more easily. Park the

vehicle on firm, level ground, apply the

handbrake firmly, then select 1st or reverse

gear (manual transmission) or the “P” position

(automatic transmission). Open the bonnet

and remove the engine oil filler cap from the

cylinder head cover, then remove the oil level

dipstick from its tube (see Section 3).

6 Raise the front of the vehicle, and support it

securely on axle stands. Remove the front

right-hand roadwheel to provide access to the

oil filter; if the additional working clearance is

required, remove also the auxiliary drivebelt

cover (two fasteners).

15 Engine oil and filter change

1•16

15.1 These tools are required when

changing the engine oil and filter

1 Drain pan - It should be fairly shallow in

depth, but wide to prevent spills

2 Rubber gloves - When removing the drain

plug and filter, it is inevitable that you will get

oil on your hands (the gloves will prevent

burns from hot oil)

3 Breaker bar - Sometimes the oil drain plug

is pretty tight, and a long breaker bar is

needed to loosen it

4 Socket - To be used with the breaker bar

or a ratchet (must be the correct size to fit the

drain plug)

5 Filter wrench - This is a metal band-type

wrench, which requires clearance around the

filter to be effective

6 Filter wrench - This type fits on the

bottom of the filter, and can be turned with a

ratchet or breaker bar (different size wrenches

are available for different types of filters)

15.7 Use the correct-size spanner or

socket to remove the oil drain plug and

avoid rounding it off

15.9 Since the oil filter is usually on very

tight, you’ll need a special wrench for

removal. DO NOT use the wrench to

tighten the new filter. Pack rag under the

filter before removal to minimise the mess

Every 10 000 miles

Frequent oil changes are the

best preventive maintenance

the home mechanic can give

the engine, because ageing

oil becomes diluted and contaminated,

which leads to premature engine wear.

Note: It is

antisocial and

illegal to dump

oil down the

drain. To find

the location of

your local oil

recycling bank,

call this

number free.