Carrier 30AWH004HB / 30AWH006HB / 30AWH008HB / 30AWH012HB. Service Manual - page 2

17

30AW

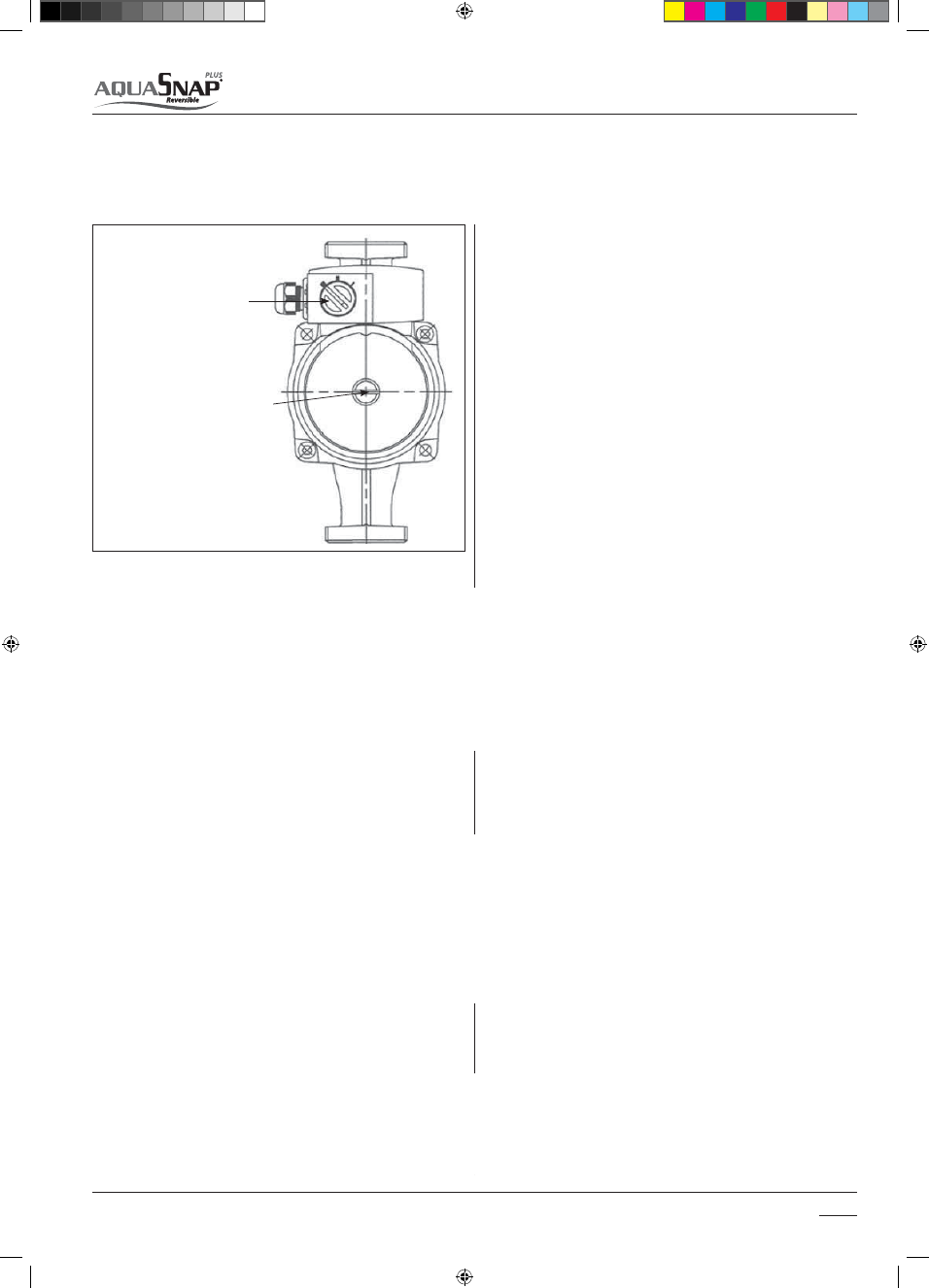

3.3.6 Circulating water Pump (only H version)

Water flow setting

Anti-seizing pump

Speed selector

Shaft protection plug

Pumps have a manual speed selector (3 speed settings) which allow for

adjustment of speed to match the requirements of the system.

The 30AWH__H units are equipped with protection against the seizing

of the pump motor shaft. To allow this function, do not empty the

system or disconnect the power during long periods of inactivity.

In any case, if the pump rotor shaft seizes after a long period of

inactivity, the user must do the following to unblock it:

Pump has to be selected in order to provide nominal water flow at

expected water loop pressure loss.

Centrifugal Pump Curves.

Water loop pressure loss estimation at nominal water flow is needed to

define water pump size.

Pump Speed Setting procedure:

The best speed setting will provide adequate circulation and provide

UIFDPSSFDUøPXBOESFUVSOUFNQFSBUVSFEJòFSFOUJBMT5IJTXJMMBDIJFWF

NBYJNVNFDPOPNZBOEFóDJFODZ

Set the speed selector to minimum (one)

1.

Open all thermostatic or manual radiator valves to maximum

2.

Set any room thermostatic controls to maximum

3.

Start up system and pump should start

4.

8BJU_NJOTBOENFBTVSFXBUFSUFNQFSBUVSFEJòFSFOUJBM

5.

(leaving water temperature-entering water temperature)

8BUFS5FNQFSBUVSF%JòFSFOUJBMTIPVMECF¡$JG8BUFSEFMUB

6.

temperature is more than 6°C select a higher pump speed An

BMUFSOBUJWFTPMVUJPOJTNFBTVSFXBUFSQSFTTVSFEJòFSFOUJBMCFUXFFO

unit water IN-OUT pipes and select pump speed to match the unit

nominal water flow (see unit available static pressure curves).

- Disconnect the power

- Remove the front panel

- Unscrew the shaft-protection plug on the back of the pump

- Insert a screwdriver in the slot and turn the rotor shaft

- Remount the protection plug

- Reconnect the power

3.3.7 External water pump selection (X and NX version)

Pump Speed Setting procedure is the same used for 30AWH---H version.

"OBMUFSOBUJWFTPMVUJPOJTNFBTVSFXBUFSQSFTTVSFEJòFSFOUJBMCFGPSFBOE

after external water pump and select pump speed to match the unit

nominal water flow (see water pump curves)

Installation

3

14-03-2011 14:41:26