Volkswagen Golf Variant / Jetta. Manual - part 438

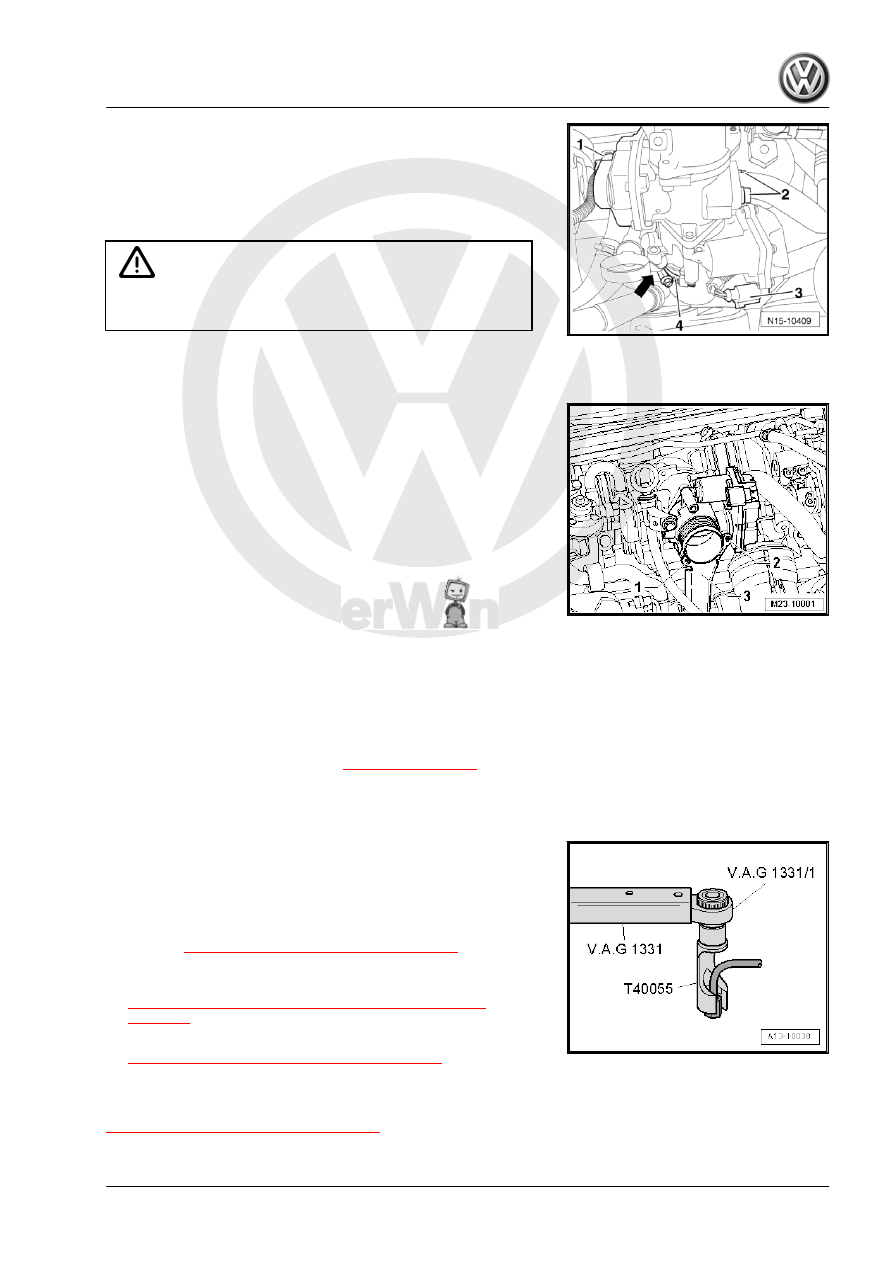

Throttle Valve Control Module - J338- -3-.

– Loosen the clamp -4- and remove the charge air hose.

– Remove the oil dipstick bracket -arrow-.

– Disconnect the connecting pipe -2-.

Caution

Make sure the connecting pipe decoupling element does not

bend or stretch. Cracks could develop.

– Remove the bolts -1 and 2- from the Throttle Valve Control

Module - J338- and remove the bracket.

– Remove the intake manifold bolts with a Socket - Xzn 8 -

T40159- in a diagonal sequence working from the outside

toward the inside.

– Remove intake manifold.

Installing:

Install in reverse order of removal. Note the following:

• Always replace the seals.

• When installing the high pressure line or fuel lines, make sure

no dirt enters the fuel system.

• Only remove the plugs right before installing the fuel lines.

• Do not change the angles of the high pressure lines

• Make sure the line connections are secure.

• Do not interchange the supply line and the return line.

– Tighten the intake manifold bolts in a diagonal sequence start‐

ing from the inside toward the outside:

• Tightening specification -item 2-

– Tighten the high pressure line union nuts hand-tight.

– Make sure the high pressure line is without tension.

– Tighten the high pressure line using the Torque Wrench 1331

5-50Nm - VAG1331- with Torque Wrench 1331 Insert - Re‐

versible Ratchet - VAG1331/1- and Union Nut Socket -

T40055- .

Tightening Specifications:

• Refer to

⇒ “3.3 Overview - Fuel System”, page 311

. Overview

- Fuel System

• Overview - Intake Manifold with Attachments. Refer to

⇒ “3.12 Overview - Intake Manifold with Attachments”,

.

– Fill the fuel system. Refer to

⇒ “3.9 Fuel System, Filling/Bleeding”, page 328

3.14

Overview - Air Filter

⇒ “3.14.1 Overview - Air Filter”, page 335

3.14.1

Overview - Air Filter

3. Diesel Direct Injection System

335