Volkswagen Golf Variant / Jetta. Manual - part 436

take manifold.

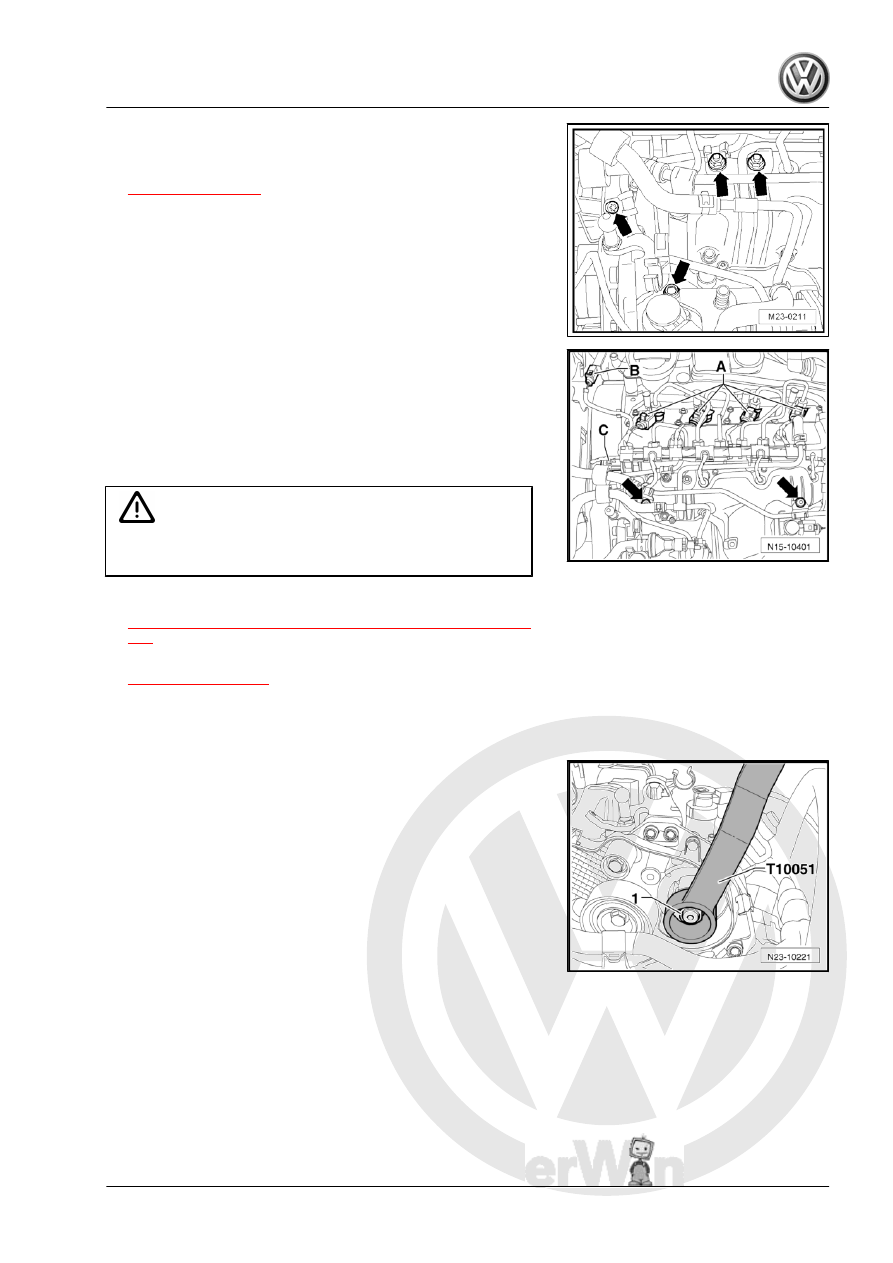

– Remove the protective strip, if equipped -item 1-

– Disconnect from the fuel injectors -A-, the Exhaust Pressure

Sensor 2 - G451- -B- and the Fuel Pressure Sensor - G247-

-C-.

– Remove the coolant line bolts -arrows- from the intake mani‐

fold and lay the line in front of the intake manifold.

– Unclip the wiring harness from the wiring guide for the glow

plugs.

Caution

Always follow the procedure »Glow Plug Connectors, Remov‐

ing and Installing«.

– Remove the glow plug connectors. Refer to

⇒ “1.3 Glow Plug Connectors, Removing and Installing”, page

– Remove the high pressure line -item 21-

between the high pressure fuel pump

and rail element (high pressure reservoir).

– Remove the toothed belt sprocket from the high pressure fuel

pump.

– Hold the high pressure fuel pump hub with the Counterhold -

Camshaft Gear - T10051- and remove the nut -1-.

3. Diesel Direct Injection System

327