Volkswagen Golf Variant / Jetta. Manual - part 419

♦

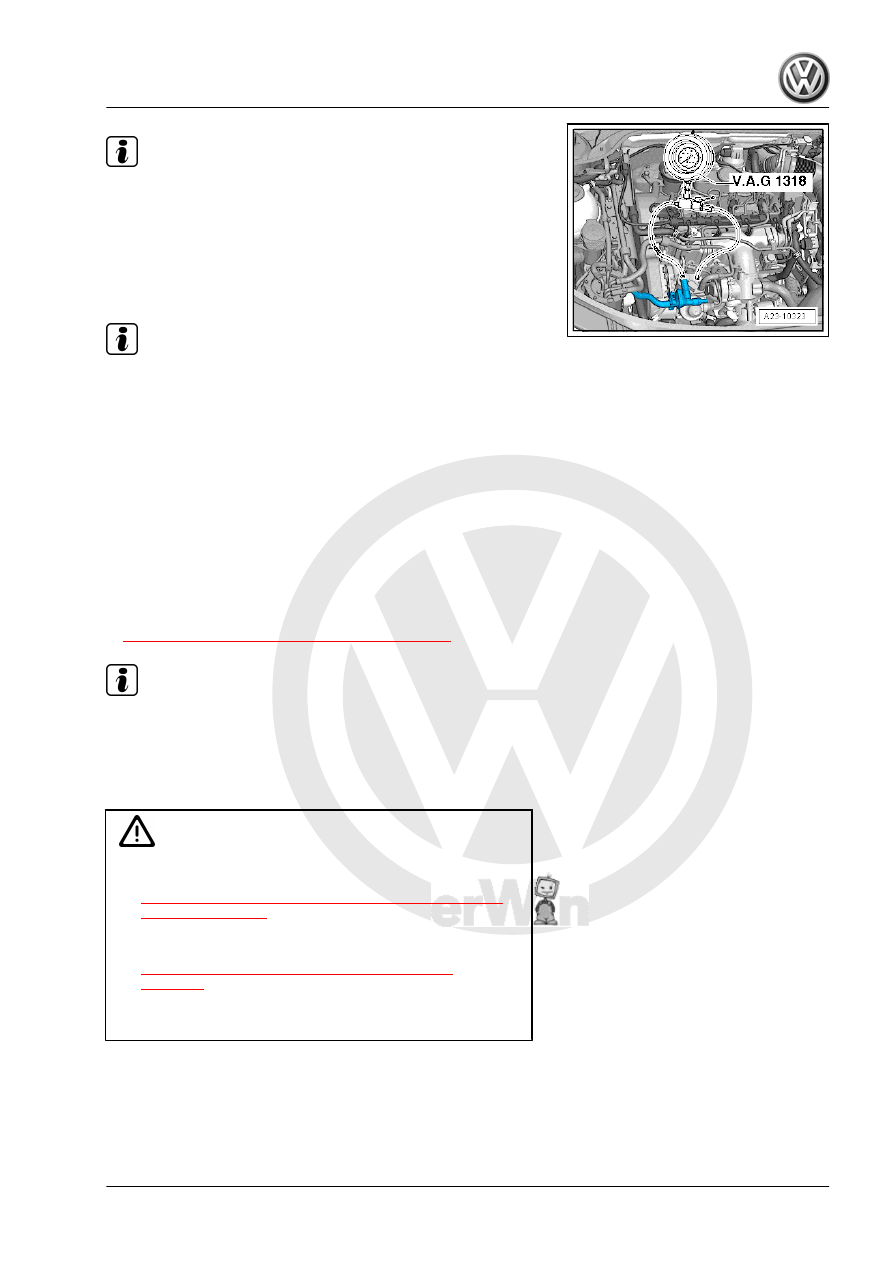

The Diesel Pressure Tester Kit - VAS6551- is switched on in

the fuel supply line.

♦

Illustration shows VAG1318, use Diesel Pressure Tester Kit -

VAS6551- .

– Connect the Vehicle Diagnostic Tester and perform the Gui‐

ded Function “Check electrical fuel pumps”.

Note

The fuel pump is now activated for 30 seconds.

– Let the fuel pumps run until the highest fuel pressure is

reached.

• Specified value: minimum 3.5 bar (50.76 psi)

If the specified value is not obtained:

Check the connection between the fuel pressure gauge and fuel

line for leaks.

Check the pressure gauge for leaks.

Check the fuel lines and their connections for leaks.

Fuel filter clogged?

Check the delivery rate of the Transfer Fuel Pump - G6- . Refer

to

⇒ “6.4.1 Fuel Delivery Rate, Checking”, page 252

Note

Check the fuel system for leaks.

6.6

Auxiliary Fuel Pump - V393- (Inline Fuel

Pump), Removing and Installing

DANGER!

♦ Observe safety precautions when working on fuel supply.

Refer to

⇒ “1 Safety Precautions when Working on Fuel Supply

♦ Pay attention to the guidelines for clean working condi‐

tions. Refer to

⇒ “2 Guidelines for Clean Working Conditions”,

Always pay attention to these instructions before and during

work.

Special tools and workshop equipment required

♦ Torque Wrench 1331 5-50Nm - VAG1331-

♦ Hose Clip Pliers - VAS6362-

6. Fuel Supply System, Servicing

259