Volkswagen Golf Variant / Jetta. Manual - part 380

the cylinder head cover correctly.

Note

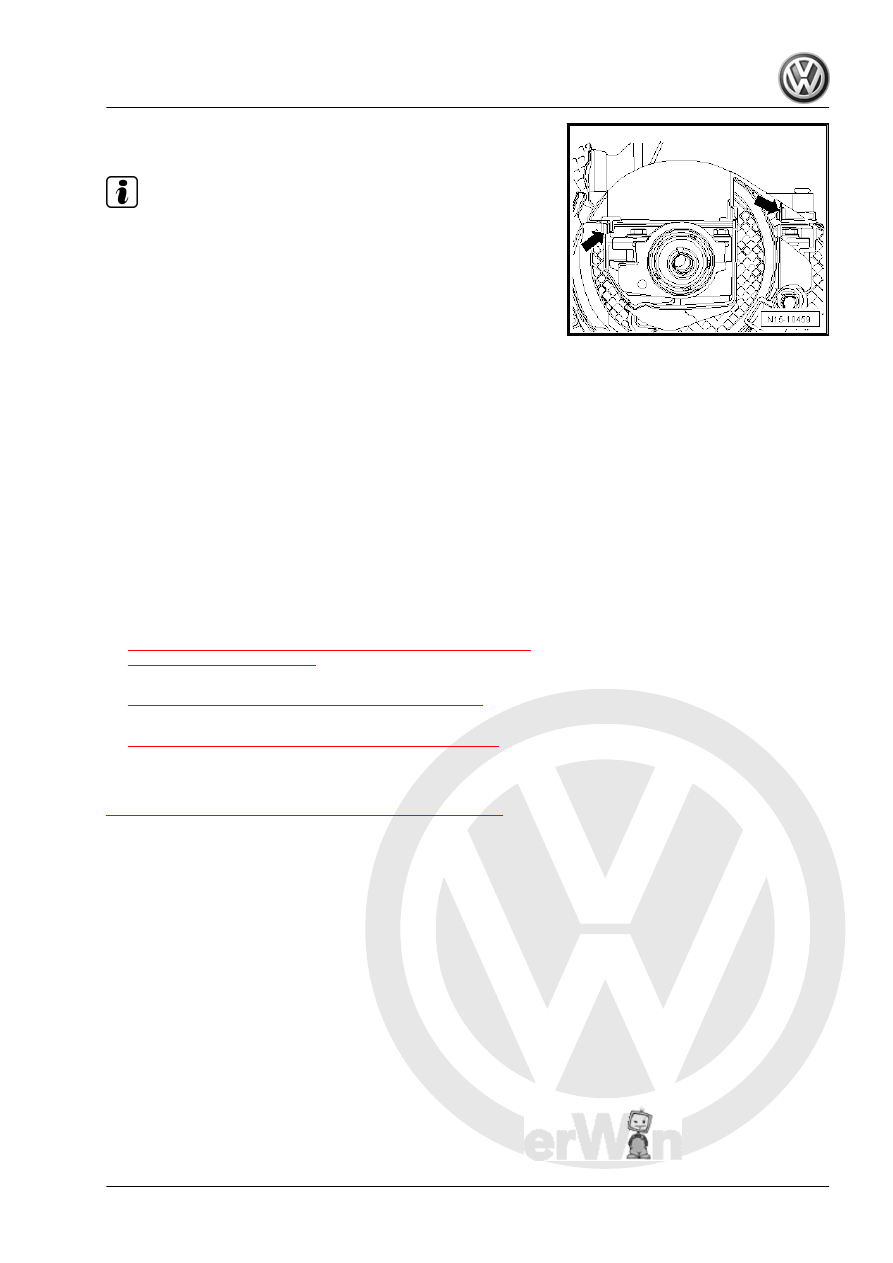

The camshaft is removed here for clarity.

– Press the toothed belt guard upper section near the clips

-arrows- against the cylinder head cover until the clips engage

with each other. Use a screwdriver to press the guard if nec‐

essary.

– Check the clearance between the hub and the toothed belt

guard upper section.

– Install the right front wheel housing liner. Refer to ⇒ Body

Exterior; Rep. Gr. 66 ; Wheel Housing Liner .

50 ; Noise Insulation .

Further assembly is performed in the reverse order of the remov‐

al. Note the following:

• Route the fuel hoses without kinks.

• Check the fuel hoses for secure fit.

• Do not interchange the supply and return lines (the return line

is blue or has a blue marking, the supply line is white or has a

white marking).

• Clip the fuel hoses back into the retainers.

– Install the Auxiliary Fuel Pump - V393- . Refer to

⇒ “6.6 Auxiliary Fuel Pump V393 (Inline Fuel Pump), Remov‐

.

– Install the fuel filter. Refer to

⇒ “6.3 Fuel Filter, Removing and Installing”, page 251

.

– Install the engine cover. Refer to

⇒ “1.4 Engine Cover, Removing and Installing”, page 90

.

1.7

Cylinder Head, Removing and Installing

⇒ “1.7.1 Cylinder Head, Removing and Installing”, page 103

.

1.7.1

Cylinder Head, Removing and Installing

Special tools and workshop equipment required

♦ Guide Tool - Cylinder Head - 3070-

♦ Diesel Injection Pump Locking Pin - 3359-

♦ Crankshaft Stop - T10050-

♦ Counterhold - Camshaft Gear - T10051-

♦ Puller - Camshaft Sprocket - T10052-

♦ Socket - Xzn 10 - T10385-

♦ Torque Wrench 1331 5-50Nm - VAG1331-

♦ Torque Wrench 1332 40-200Nm - VAG1332-

♦ Shop Crane - Drip Tray - VAS6208-

♦ Engine Bung Set - VAS6122- (not illustrated)

1. Cylinder Head

103