Nissan Qashqai (2007-2010). Manual - part 647

FAX-10

< ON-VEHICLE REPAIR >

[2WD]

FRONT WHEEL HUB AND KNUCKLE

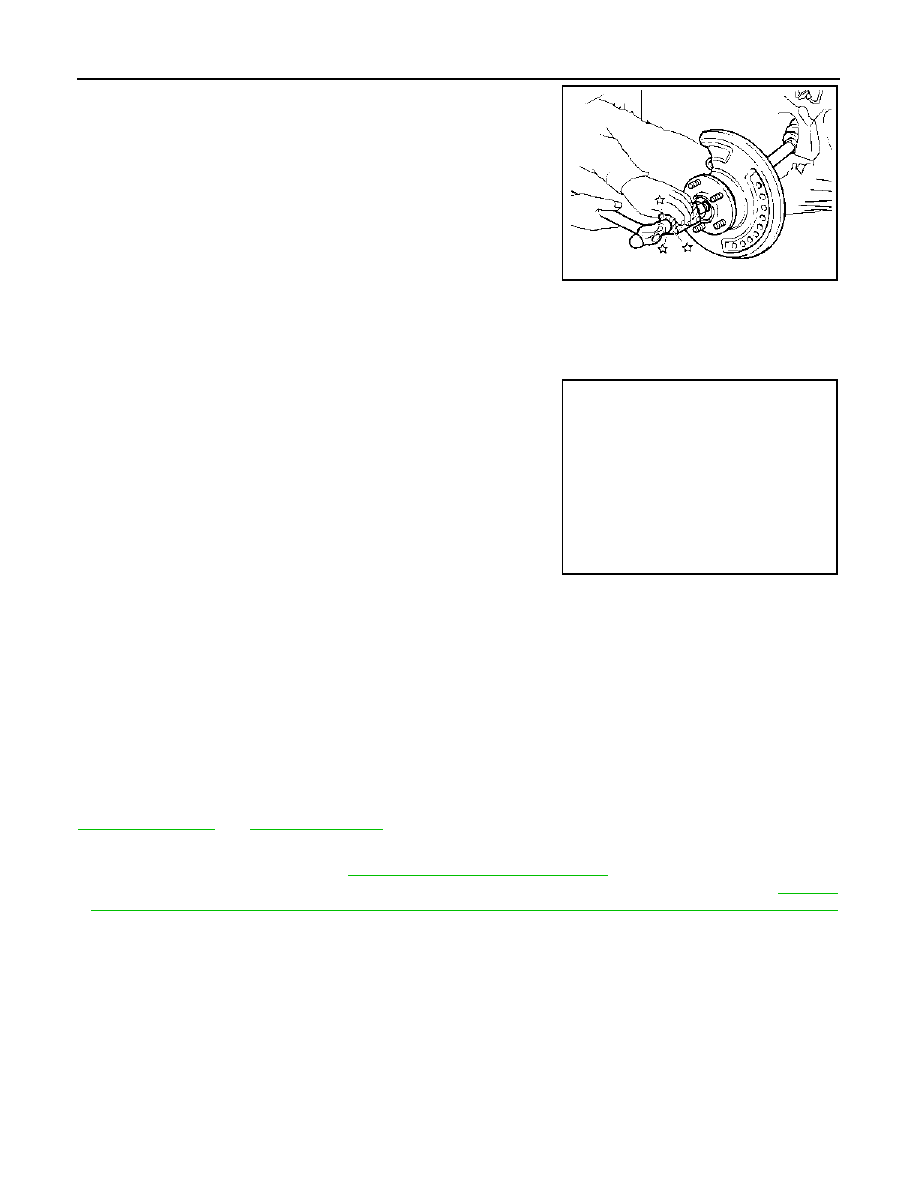

7.

Patch hub lock nut with a piece of wood. Hammer the wood to

disengage wheel hub and bearing assembly from drive shaft.

Remove the hub lock nut.

CAUTION:

• Never place drive shaft joint at an extreme angle. Also be

careful not to overextend slide joint.

• Never allow drive shaft to hang down without support for

housing (or joint sub-assembly), shaft and the other parts.

NOTE:

Use suitable puller, if wheel hub and bearing assembly and drive

shaft cannot be separated even after performing the above pro-

cedure.

8.

Remove wheel hub and bearing assembly.

Steering Knuckle

1.

Remove wheel hub and bearing assembly, and then remove splash guard.

2.

Remove cotter pin (1) of steering outer socket, and then loosen

the nut.

3.

Remove steering outer socket (2) from steering knuckle (3)

using the ball joint remover so as not to damage ball joint boot

(4).

CAUTION:

Temporarily tighten the nut to prevent damage to threads

and to prevent the ball joint remover from suddenly coming

off.

4.

Remove transverse link from steering knuckle.

5.

Remove steering knuckle from strut assembly.

6.

Remove steering knuckle form vehicle.

INSTALLATION

Note the following, and install in the reverse order of the removal.

• Under unladen conditions perform the final tightening of each parts removed when removing wheel hub and

bearing assembly and steering knuckle.

Inspection

INFOID:0000000000970483

INSPECTION AFTER REMOVAL

Check components for deformation, cracks, and other damage. Replace if there are.

Ball Joint Inspection

Check boots of transverse link and steering outer socket ball joint for breakage, axial play, and torque. Refer to

.

INSPECTION AFTER INSTALLATION

• Check the wheel alignment. Refer to

FSU-7, "Wheel Alignment Inspection"

.

• Adjust neutral position of steering angle sensor after checking the wheel alignment. Refer to

"ADJUSTMENT OF STEERING ANGLE SENSOR NEUTRAL POSITION : Special Repair Requirement"

(with ESP).

JPDIF0003ZZ

JPDIF0024ZZ