Content .. 1776 1777 1778 1779 ..

Nissan Qashqai (2007-2010). Manual - part 1778

LAN

MAIN LINE BETWEEN TCM AND BCM CIRCUIT

LAN-1137

< COMPONENT DIAGNOSIS >

[CAN SYSTEM (TYPE 78)]

C

D

E

F

G

H

I

J

K

L

B

A

O

P

N

MAIN LINE BETWEEN TCM AND BCM CIRCUIT

Diagnosis Procedure

INFOID:0000000001058230

INSPECTION PROCEDURE

1.

CHECK CONNECTOR

1.

Turn the ignition switch OFF.

2.

Disconnect the battery cable from the negative terminal.

3.

Check the following terminals and connectors for damage, bend and loose connection (connector side

and harness side).

-

Harness connector E105

-

Harness connector M77

Is the inspection result normal?

YES

>> GO TO 2.

NO

>> Repair the terminal and connector.

2.

CHECK HARNESS CONTINUITY (OPEN CIRCUIT)

1.

Disconnect the following harness connectors.

-

Harness connector F121 and E7

-

Harness connector E105 and M77

2.

Check the continuity between the harness connectors.

Is the inspection result normal?

YES

>> GO TO 3.

NO

>> Repair the main line between the harness connectors E7 and E105.

3.

CHECK HARNESS CONTINUITY (OPEN CIRCUIT)

1.

Disconnect the connector of BCM.

2.

Check the continuity between the harness connector and the BCM harness connector.

Is the inspection result normal?

YES (Present error)>>Check CAN system type decision again.

YES (Past error)>>Error was detected in the main line between the TCM and the BCM.

NO

>> Repair the main line between the harness connector M77 and the BCM.

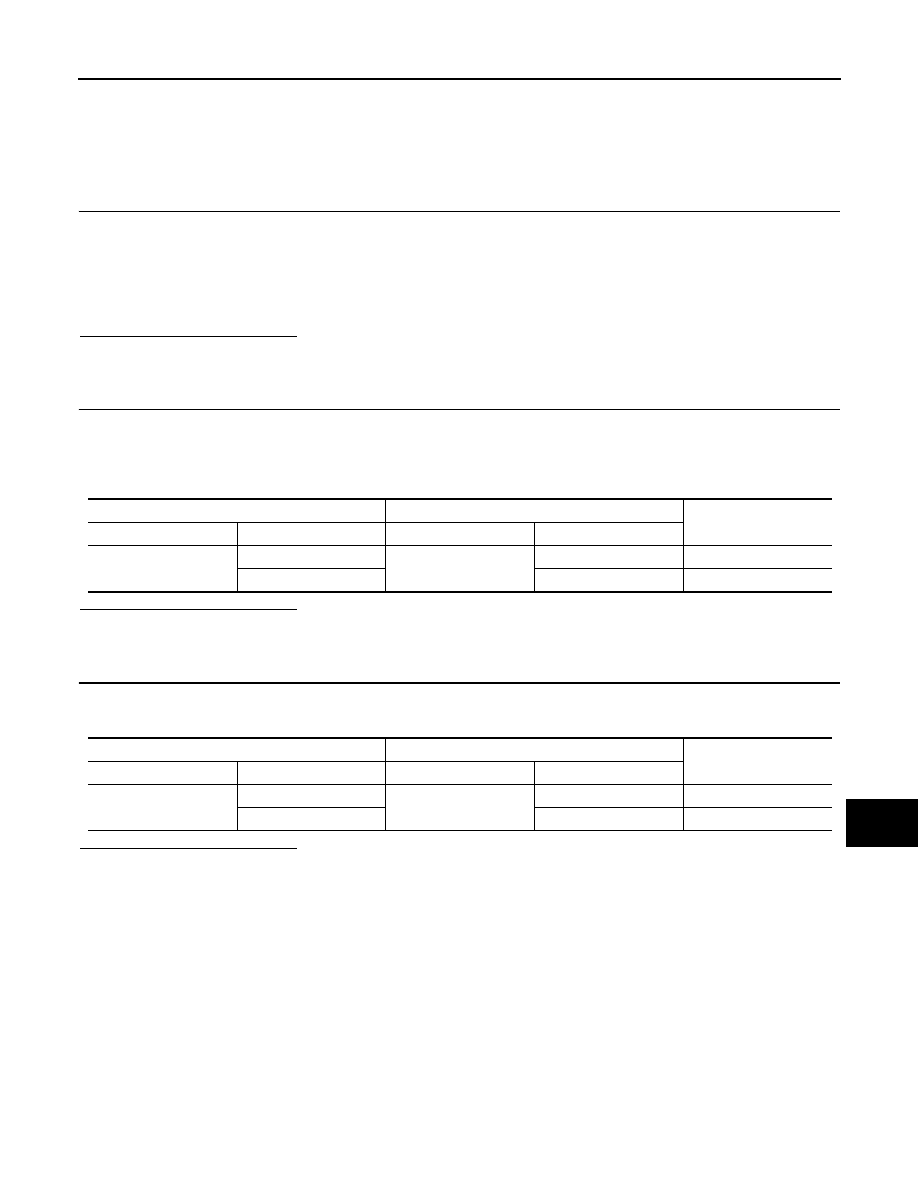

Harness connector

Harness connector

Continuity

Connector No.

Terminal No.

Connector No.

Terminal No.

E7

2

E105

52

Existed

1

51

Existed

Harness connector

BCM harness connector

Continuity

Connector No.

Terminal No.

Connector No.

Terminal No.

M77

52

M65

19

Existed

51

20

Existed