Lotus Elise / Lotus Exige. Instruction - part 99

Lotus Service Notes Section PL

Page 10

Demist:

As the control is turned clockwise from

the face level vents symbol towards the

footwell symbol, the stepper motor turns the

rotary flap to progressively open the wind-

screen vents. The rod connecting the rotary

flap to the footwell flap is arranged to close

the footwell vents in opposite proportion, until

at the screen symbol, all airflow is directed to

the windscreen. Select a warm temperature

setting and a suitable fan speed.

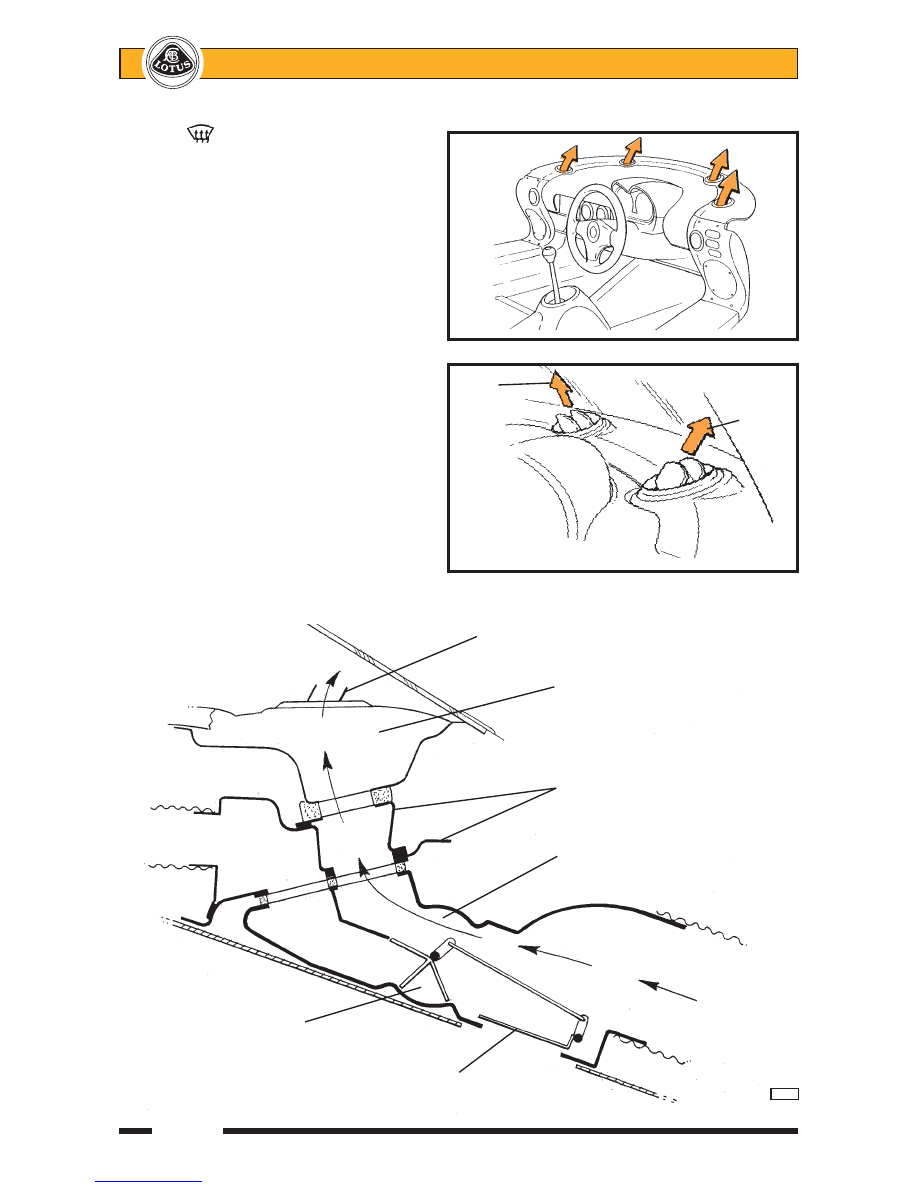

Full Defrost Performance

For maximum defrost performance, turn

the distribution knob fully clockwise and se-

lect maximum temperature and fan speed. On

cars with adjustable windscreen vents, direct

the centre pair of screen vents slightly rear-

wards, and the end pair of vents forwards as

shown in the illustration.

Ventilation Shut-Off

To close off the ventilation, which may

be desirable in heavy traffic to reduce the in-

duction of fumes into the car, turn off the fan,

turn the distribution control fully

counterclockwise to the face level vent posi-

tion, and instructionly shut off each of the face

level vents.

FULL DEFROST

PERFORMANCE

ohs98

Inner

Outer

vent

vent

direction

direction

Windscreen vent

Demist duct in

fascia top panel

Scuttle baffle panel

Windscreen port open

From

climate

Face level port closed

chamber

Footwell flap closed

p102c