Lotus Elise / Lotus Exige. Instruction - part 97

Lotus Service Notes Section PL

Page 2

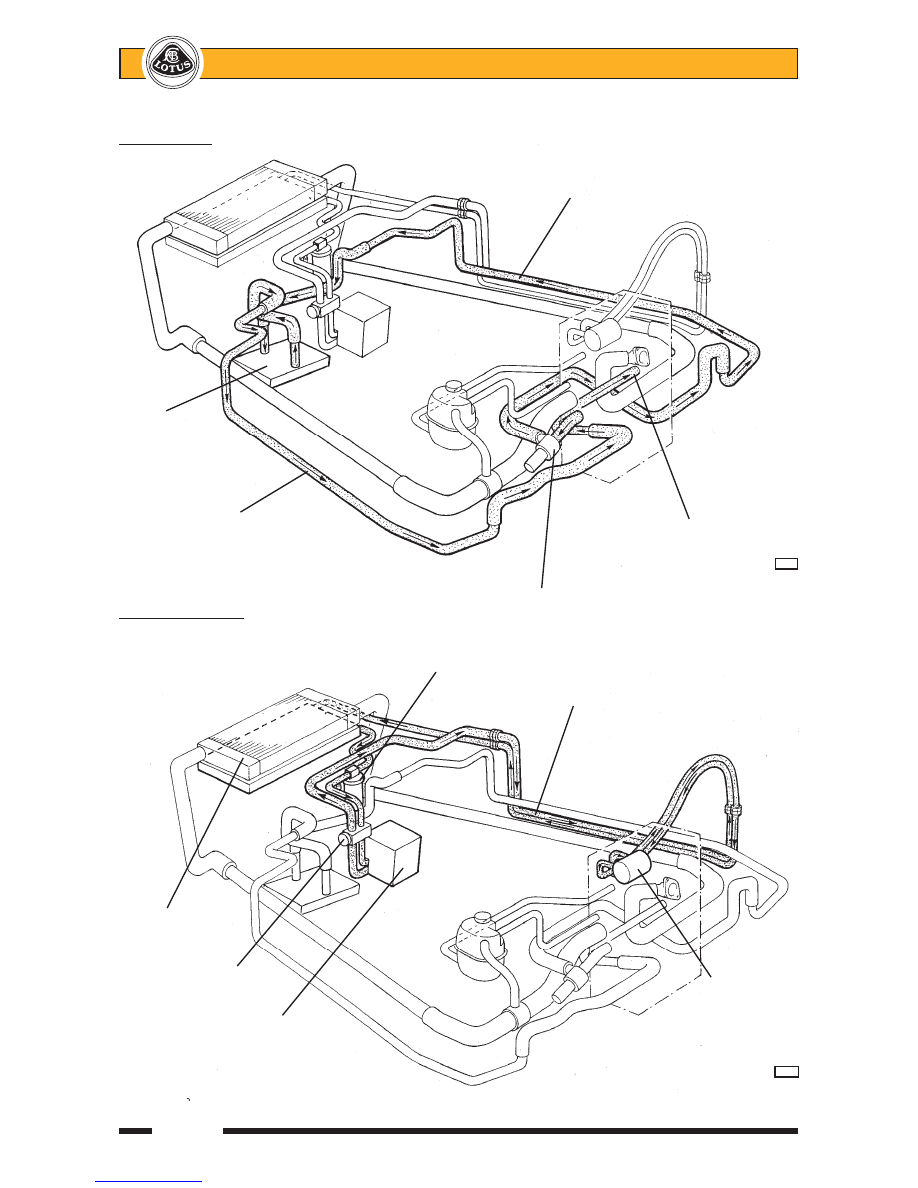

Heater Circuit

Water feed pipe along outside

of RH chassis siderail

Heater

matrix

Water return pipe

along outside of

Water return to

LH chassis siderail

engine side of

thermostat

p77c

Coolant re-circulation pump

Refrigerant Circuit

Receiver-drier

Feed & return pipes

along outside of RH

chassis siderail

Condenser

Expansion valve

Compressor

Evaporator casing

p78c