Lotus Elise / Lotus Exige. Instruction - part 66

Lotus Service Notes Section KH

Page 9

exchanger to the heater water return pipe. This device transfers heat from the engine coolant to the oil after a

cold start, and conversely, in conditions of high oil temperature transfers heat from the oil to the coolant.

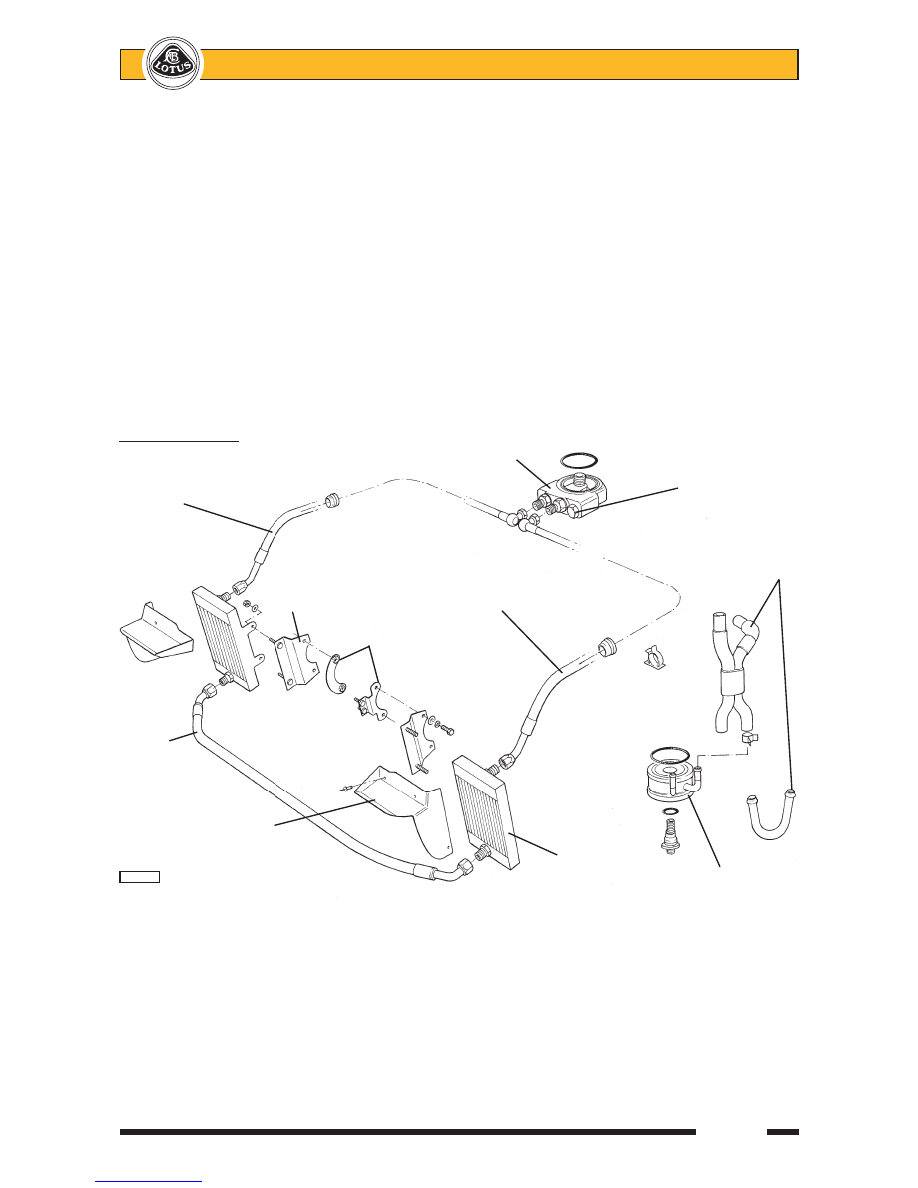

Front Mounted Air/Oil Coolers

On cars so fitted, front mounted oil/air radiators are mounted ahead of each front wheel arch and fed with

air from intakes either side of the main engine radiator intake in the body nose. 'Single oil cooler’ cars are

equipped with an oil cooler ahead of only the LH front wheel, but use the same hoses as twin oil cooler cars,

with a joiner union attached to a bracket in place of the symetrically opposite RH cooler.

On all cars with front mounted oil cooler(s), the oil/water heat exchanger is replaced by a sandwich plate

incorporating oil take-off feed and return unions, with the redundant coolant hoses interconnected by a 'U' pipe.

A thermostat incorporated into the sandwich plate begins to open at 72ºC, and is fully open at 80ºC. When

open, oil is directed from the sandwich plate via a flexible hose within the RH sill panel, over the front wheel

arch liner to the top connection on the RH oil cooler (or joiner union on single oil cooler cars). From an outlet

union at the bottom front of the cooler (or joiner union), another hose runs beneath the crash structure to the

bottom of the LH cooler, from the top of which oil is returned via a third hose, running through the LH sill, back

to the return union on the sandwich plate.

Each cooler is secured by a two stud bracket to the side of the crash structure, and positioned immedi-

ately ahead of the engine radiator mounting panel side extensions, which incorporate airflow apertures and

additional deflector panels on their front surfaces. Louvres in the wheelarch liner front sections allow air to

exhaust from the coolers into the wheelarches.

Oil Cooler Layout

Oil cooler

sandwich plate

Cooler feed hose

Oil cooler

in RH sill

thermostat

Heat exchanger

Cooler

hoses or by-pass

mounting

Cooler return hose

plate

in LH sill

Nut plates

Cooler

inter-

connection

hose

Air deflector

panel

LH oil

pl4603mt

cooler

Oil/water

heat exchanger