Snowmobile Arctic Cat (2006 year). Instruction - part 18

68

MAINTENANCE

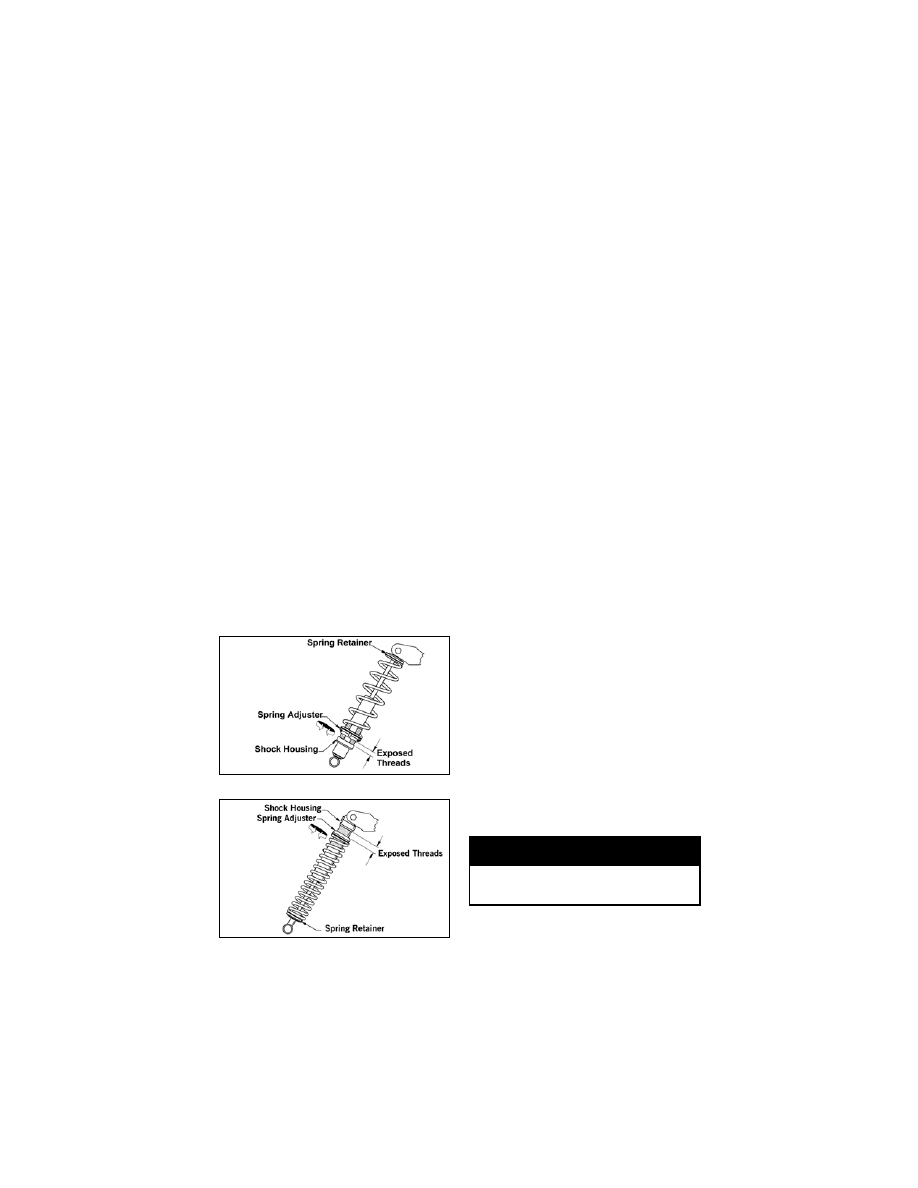

The front shock springs are individ-

ually adjustable for the terrain con-

ditions and driving style of the

operator. The spring adjuster has

been set at the factory so the correct

amount of threads are exposed

between the spring adjuster and the

shock housing as an initial setting.

Additional ski pressure can be

obtained by tightening the spring

t e n s i o n ; s k i p r e s s u r e c a n b e

decreased by relaxing spring ten-

sion.

N OT E : E q u a l a d j u s t m e n t s

should be maintained on both

sides of the snowmobile.

To adjust spring tension, rotate the

entire spring in whichever direction

is desired. If after adjusting spring

tension you note the snowmobile

front end wants to pitch, relax the

spring tension on the side that is

pitching. If both sides are pitching,

relax the spring tension on both

sides.

NOTE: The spring adjuster will

normally rotate with the spring.

734-501B

734-500B

Adjusting Front Shocks (Fox Air

Shocks)

NOTE: It is recommended to

monitor the air pressure in the air

shocks once every month.

NOTE: Adjusting air shocks

may be done by the snowmobile

owner if qualified to do so. If the

owner does not feel qualified,

take the snowmobile to an autho-

r i z e d A rc t i c C a t S n ow m o b i l e

dealer for this service. This ser-

v i c e i s a t t h e d i s c r e t i o n a n d

e x p e n s e o f t h e s n o w m o b i l e

owner.

The air shocks are individually

adjustable for the terrain conditions

and driving style of the operator.

The shocks are preset at 3.5 kg/cm

2

(50 psi) as an initial setting (4.2 kg/

cm

2

(60 psi) on the M-7 LE); how-

ever, it is possible to “fine tune” the

shocks to match the operator ’s

weight, riding style, and terrain con-

ditions.

NOTE: Care should be taken to

h a v e e q u a l p r e s s u r e i n t h e

s h o ck s b e fo r e o p e r a t i n g t h e

snowmobile.

To increase or decrease air pressure,

use the following procedure.

NOTE: When adjusting air pres-

sure, all weight must be removed

from the front suspension, and

the shock absorbers must be fully

extended.

NOTE: Adding air pressure will

increase the air spring force;

r e d u c i n g a i r p r e s s u r e w i l l

decrease air spring force.

1. Remove the air valve cap from

the shock.

! WARNING

Do not exceed 105 kg/cm

2

(150

psi) in the shock.