Snowmobile Polaris Two Stroke (2007 year). Instruction - part 71

11.21

BATTERY & ELECTRICAL SYSTEMS

11

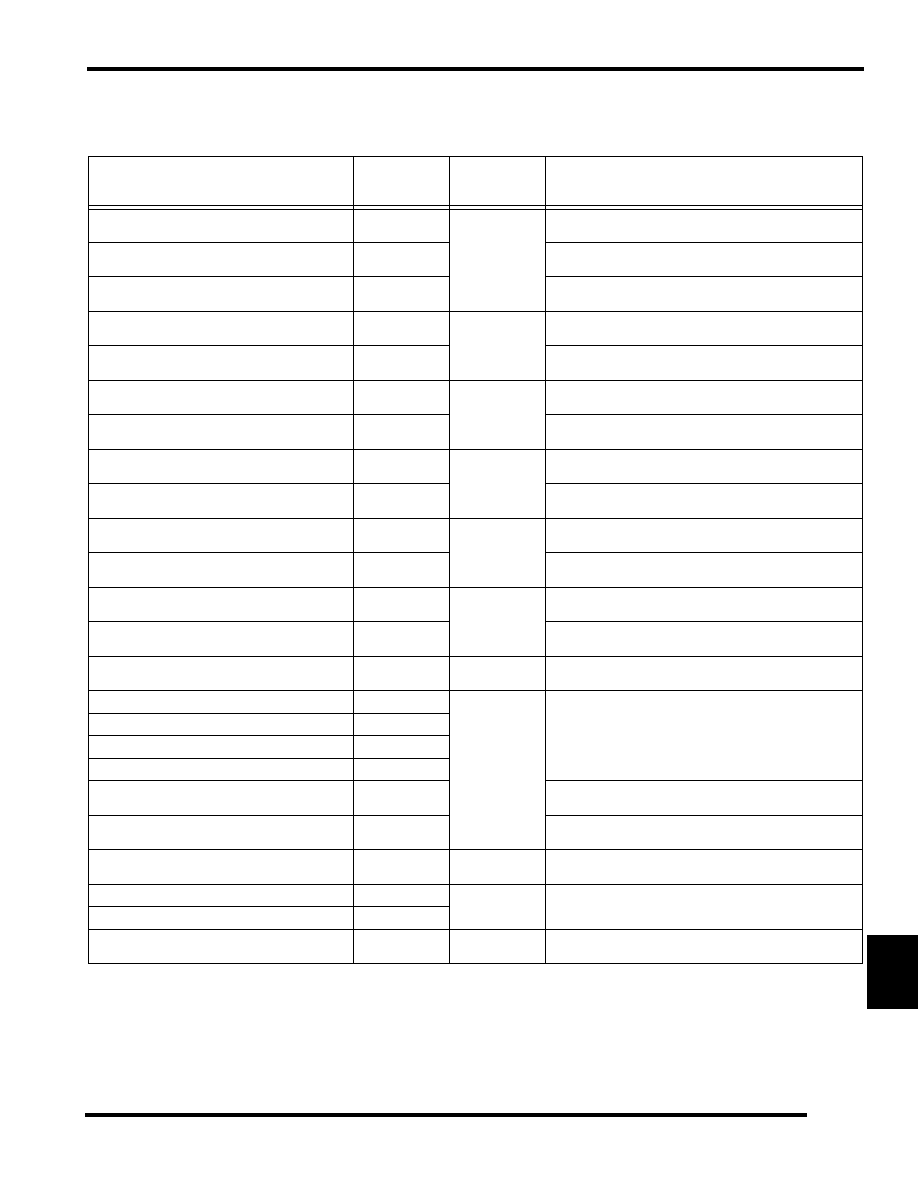

Diagnostic Trouble Codes (DTCs)

2007 CFI Diagnostic Trouble Codes

T

ROUBLE

C

ODE

P-C

ODE

MFD B

LINK

C

ODE

D

ESCRIPTION

Throttle Position Sensor Unrealistic Transition

P0120

1

TPS signal changes too rapidly to be correct. Can be caused by faulty

connections or a faulty TPS.

Throttle Position Sensor Voltage High

P0123

TPS signal is above 4.39 Vdc. Can be caused by a faulty wire

connection or faulty TPS.

Throttle Position Sensor Voltage Low

P0122

TPS signal is below 0.7 Vdc. Can be caused by a faulty wire

connection or faulty TPS.

Engine Coolant Temperature Sensor Voltage High

P0118

2

Sensor signal is above 4.8 Vdc. Can be caused by a faulty wire

connection or faulty temperature sensor.

Engine Coolant Temperature Sensor Voltage Low

P0117

Sensor signal is below 0.1 Vdc. Can be caused by a faulty wire

connection or faulty temperature sensor.

Intake Air Temperature Circuit Voltage High

P0113

3

Sensor signal is above 4.9 Vdc. Can be caused by a faulty wire

connection or faulty TBAP.

Intake Air Temperature Circuit Voltage Low

P0112

Sensor signal is below 0.19 Vdc. Can be caused by a faulty wire

connection or faulty TBAP.

Barometric Pressure Sensor Voltage High

P0108

4

Sensor signal is above 3.23 Vdc. Can be caused by a faulty wire

connection or faulty TBAP.

Barometric Pressure Sensor Voltage Low

P0107

Sensor signal is below 1.25 Vdc. Can be caused by a faulty wire

connection of faulty TBAP.

Exhaust Temperature Sensor Circuit Voltage High

P0546

5

Sensor signal is above 4.9 Vdc for at least 2 minutes and the engine

has been running at or above 3000 RPM.

Exhaust Temperature Sensor Circuit Voltage Low

P0545

Sensor signal is below 0.06 Vdc for at least 2 minutes and the engine

has been running at or above 3000 RPM.

Detonation Sensor Circuit Voltage High

P0328

6

Engine speed is above 6000 RPM and the sensor signal is above 4.3

Vdc for at least 2 seconds.

Detonation Sensor Circuit Voltage Low

P0327

Engine speed is above 6000 RPM and the sensor signal is below 1.23

Vdc for at least 2 seconds.

Exhaust Valve Solenoid Circuit Malfunction

P1477

8

Solenoid control circuit is OPEN. Can be caused by faulty wiring,

solenoid, or ECU.

MAG Part Load Injector Circuit Open

P0261

7

OPEN circuit or short to ground. Can be caused by faulty wiring,

injector, stator or ECU.

MAG Full Load Injector Circuit Open

P1261

PTO Part Load Injector Circuit Open

P0264

PTO Full Load Injector Circuit Open

P1264

Fuel Injector Voltage Too High

P2148

Engine is running, but the injector voltage is above the acceptable

limit. Can be caused by faulty wiring, ECU or stator.

Fuel Injector Voltage Too Low

P2147

Engine is running, but the injector voltage is below the acceptable

limit. Can be caused by faulty wiring, ECU or stator.

Vehicle Speed Sensor No Signal

P0500

Steady LED

Sensor has given a speed that is not possible with given engine

conditions. Can be caused by a faulty sensor, wiring or ECU.

MAG Ignition Coil Circuit Malfunction

P0351

9

Failure within the primary circuit. Can be caused by faulty wiring,

ignition coil, or ECU.

PTO Ignition Coil Circuit Malfunction

P0352

5 Tooth CPS Signal Missing

P0335

10

Engine is running, but there is no signal from the 5 tooth CPS. Can

be caused by a faulty stator, wiring or ECU.