Snowmobile Polaris Two Stroke (2007 year). Instruction - part 42

6.19

CLUTCHING

6

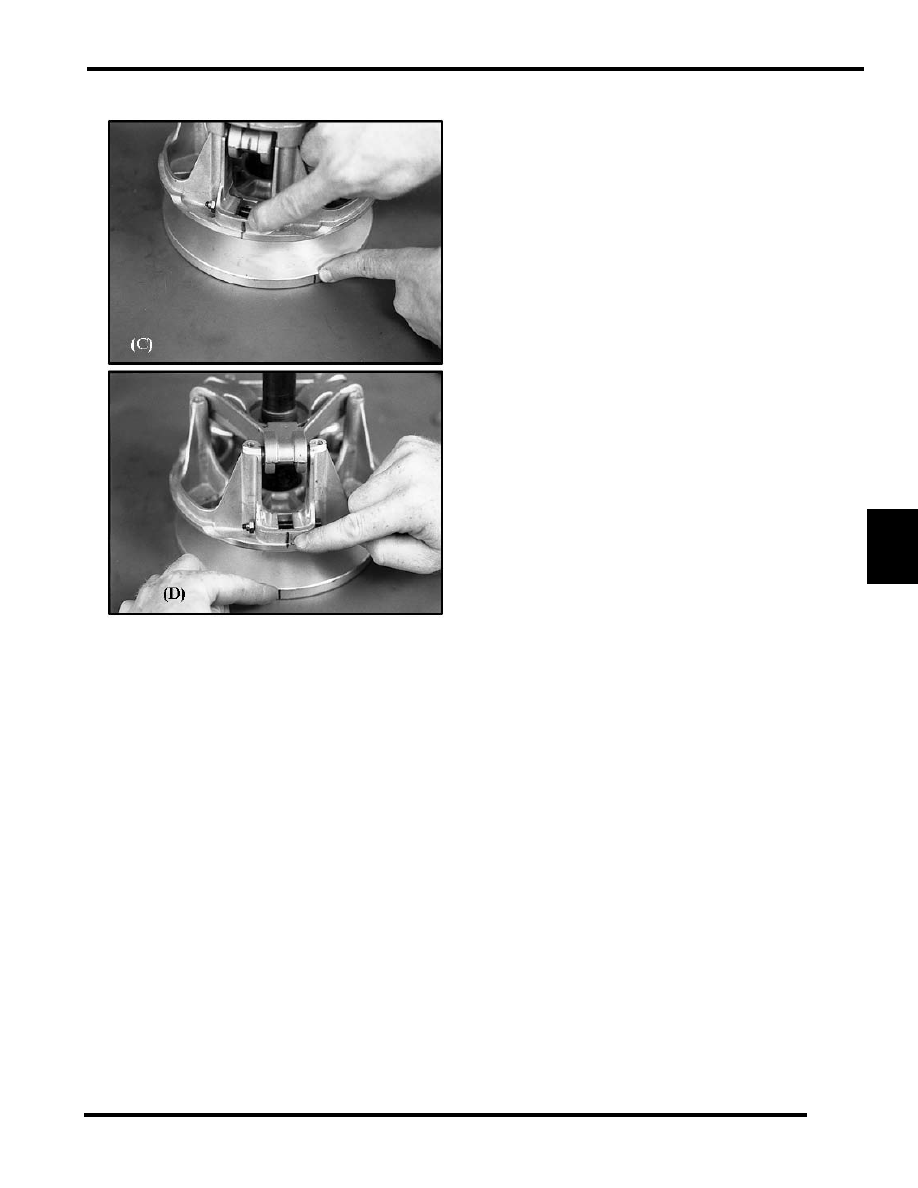

Vary the amount and thickness of spacer washers (washer

thickness may vary slightly). Re-index marked spider leg to

another tower. This can be done because spider has little effect

on overall clutch balance.

Re-indexing the spider 1/3 turn clockwise, or 1 leg, will allow

the realignment of the moveable and stationary sheaves as

previously marked (D). For EXAMPLE: 0.020" or 0.032" (0.5

- 0.8mm) washer removed - re-index spider clockwise 1/3 turn.

NOTE: Alignment marks on the sheaves should be

with in 1" (25.4mm) after final assembly and

torquing.