Snowmobile Polaris Two Stroke (2007 year). Instruction - part 28

5.5

ENGINE

5

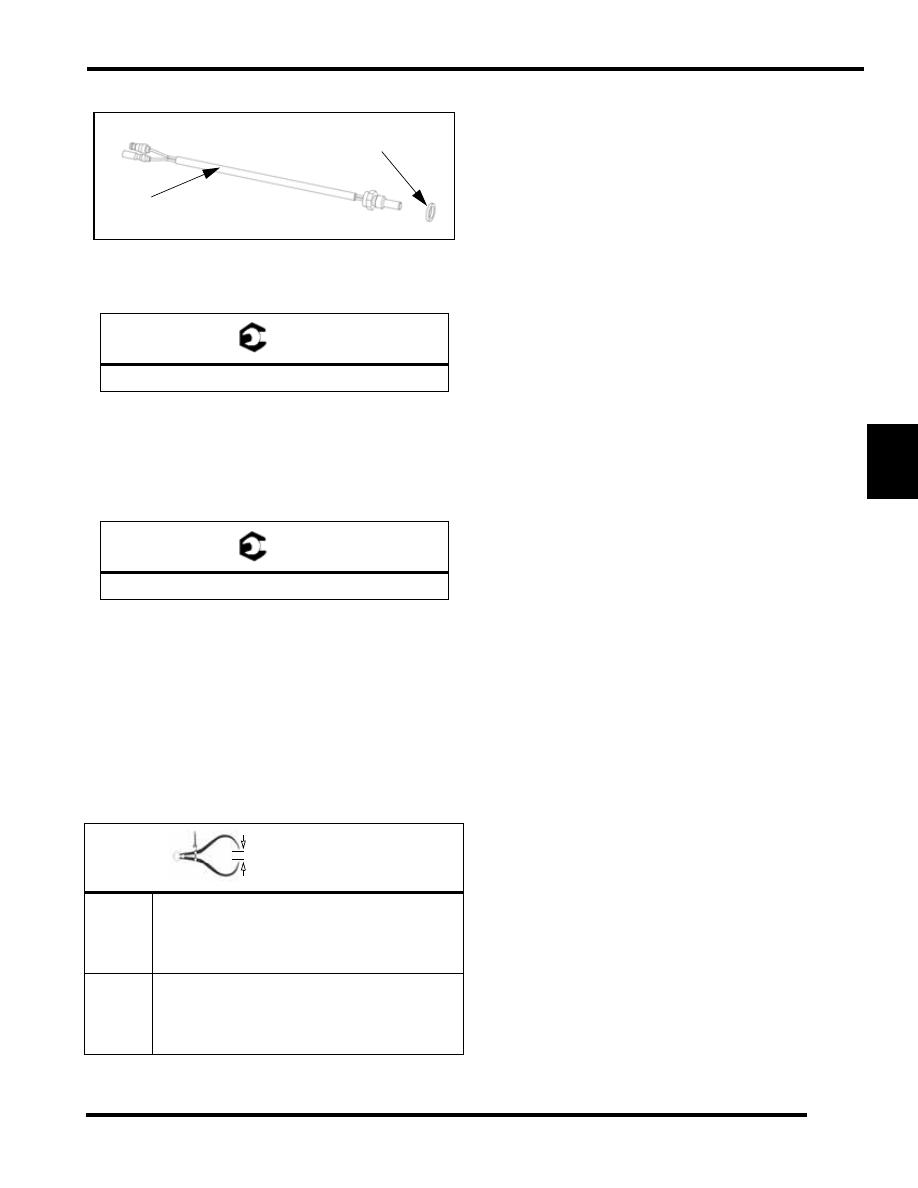

Water Temperature Sensor Replacement

1.

Remove the sensor (1) from the cylinder head.

2.

Replace the washer (2) and torque the sensor to

specification.

Engine Mount Replacement

1.

Use the correct Engine Mount Socket (PN PS-45384 or

2871989).

2.

Replace the old motor mount if necessary with new and

torque new motor mount to specification.

Cylinder Stud Installation

If you are replacing the crankcase on the 500, 600 HO, 600 CFI

or 700 CFI Liberty engines, the new cases will come with the

cylinder studs not installed, you will need to assemble the

cylinder studs to a determined length.

You will need to thread in the Dri-Lok treated portion of the stud

into the case to a determined length below. After stud assembly

remove the Dri-Lok residue from the case assembly before

assembly.

= T

Temperature Sensor: 18 ft-lb (24 N-m)

= T

28 ft.lb (37.9 N-m)

= In. / mm.

600 CFI

700 CFI

Long Studs Height (Exhaust side) = 4.13"

(105mm)

Small Stud Height (Intake side) = 2.16"

(55mm)

500/600

HO

Long Studs Height (Exhaust side) = 3.66"

(93mm)

Small Stud Height (Intake side) = 2.16"

(55mm)

1

2