Snowmobile Polaris Two Stroke (2007 year). Instruction - part 25

4.17

FUEL DELIVERY

4

CLEANFIRE INJECTION (CFI)

Injector Replacement

The Cleanfire system utilizes 3 different color injectors. If you

are replacing an injector you must replace it with the same color

injector you remove.

The color is indicated in three ways, 1) it will be on the short wire

harness that is attached to the injector, 2) the injector will have

a colored dot on the shaft of the injector 3)it is indicated on the

label of the ECU.

If the color injector is not available you may replace all injectors

with a different color and you must program the ECU to run the

new installed color.

If it is verified that an injector needs to be replaced, you must

first find out what injector color is on the unit. You can do this

by checking the decal that is located on the top portion of the

ECU or by the color band that is next to the injector on the

harness.

1.

Bleed the fuel rail. See “Fuel Rail Bleeding” on page 4.20.

2.

Remove the seat and fuel tank. See “IQ Fuel Tank

Removal” on page 10.6.

3.

If removal of the engine is needed. See “600/700 CFI

Engine Removal” on page 5.29.

4.

Replace the injectors.

5.

Install engine. See “600/700 CFI Engine Installation” on

page 5.35.

6.

Re-flash ECU with Digital Wrench.

7.

Test run.

600/700 CFI Injector Replacement

If an injector is suspect to failure please use the following

procedure to replace injector(s) on the

CFI

engine.

Using Digital Wrench, identify which injector needs to be

replaced.

NOTE: If the injector is on the upper fuel rail, only

the air box needs to be removed to gain access to

the failed injector.

NOTE: If the injector is on the lower fuel rail, engine

removal is necessary for injector access. See “600 /

700 HO CFI ENGINE” on page 5.29.

600/700 CFI Fuel Rail/Injector(s) Removal/

Installation

NOTE: When installing replacement injector(s) keep

the red protective cap on the end of the injector to

prevent damage when installed. Follow the steps

and remove when instructed to do so.

1.

Depressurize the fuel rail. See “Fuel Rail Bleeding” on

page 4.20.

2.

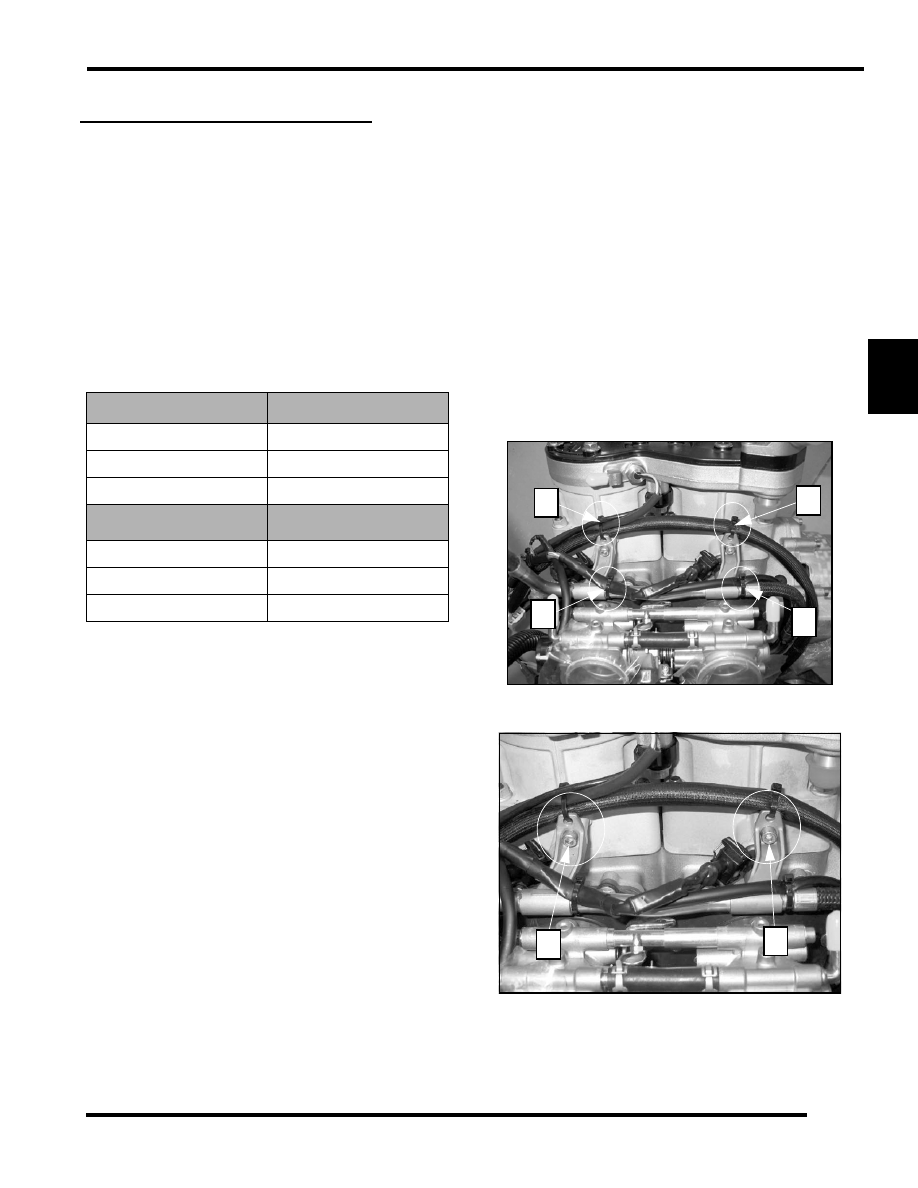

Remove the panduit straps (1-4) as shown.

3.

Remove the fuel rail by taking out the two hex bolts (5,6)

holding it to the engine.

INJECTOR

COLOR

1202853-053

Yellow

1202853-027

Blue

1202853-015

Red

INJECTOR

KITS

COLOR

2203325-053

Yellow

2203325-027

Blue

2203325-015

Red

1

4

3

2

6

5