Snowmobile Polaris 340 Edge / 550 LX (2008 year). Instruction - part 21

84

MAINTENANCE

Exhaust System

Check the exhaust system for wear or damage at approximately 2000

miles (3200 km). To inspect, allow the engine and exhaust system to

cool completely. Open the hood and inspect the muffler and pipes for

cracks or damage. Check for weak or missing retaining springs or

damper/support grommets.

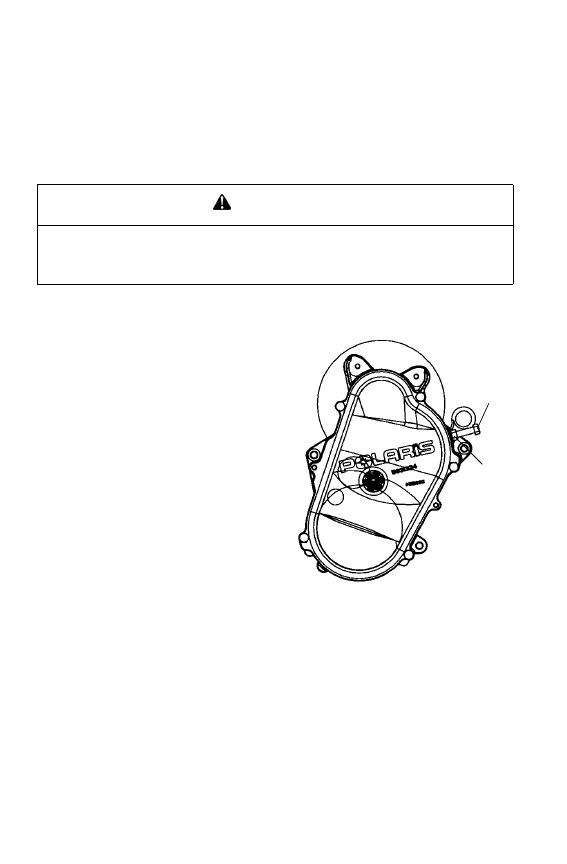

Drive Chain Tension

Check drive chain tension

weekly and before each long trip.

To obtain correct chain tension:

1. Rotate the driven clutch

counterclockwise to move all

chain slack to the tensioner

side. Lock the brake lever

lock, or have an assistant

hold the brake lever firmly.

2. Loosen the adjuster bolt jam

nut (1).

3. Finger tighten the adjuster

bolt (2) until it can no longer

be adjusted by hand, then

back off 1/4 turn.

4. Tighten the jam nut while

holding the adjuster bolt.

Torque to 21 ft. lbs. (28 Nm).

5. Release the brake lever lock.

WARNING

Hot exhaust system parts can cause serious burns. Allow adequate time for

the exhaust system to cool. Never perform this procedure with the engine

running.

1

2