Snowmobile Polaris 340 Edge / 550 LX (2008 year). Instruction - part 19

76

MAINTENANCE

Lubrication

Jackshaft Bearing

The jackshaft bearing on your model may be equipped with a grease fit-

ting, but this component is greased for life at the factory. Additional

lubrication is not required.

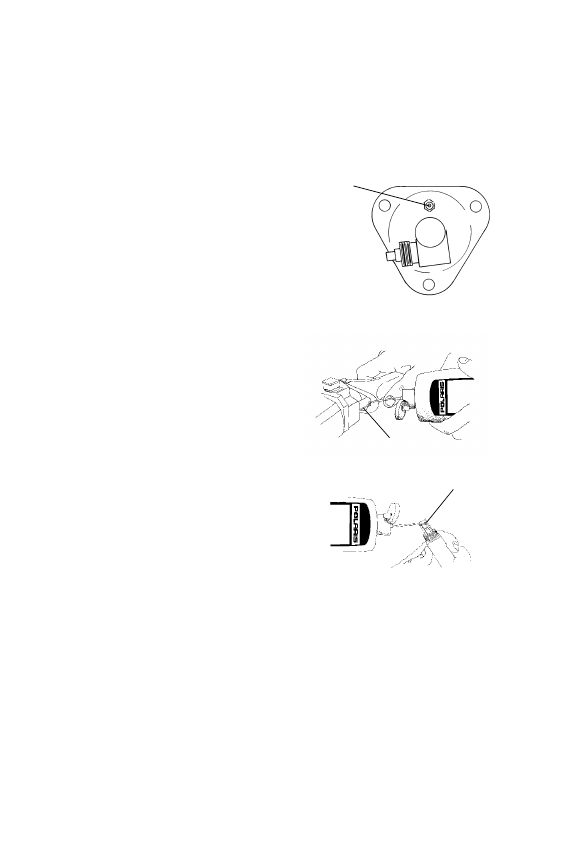

Driveshaft Bearing

Inject grease into the fitting on the

speedometer sensor housing until

grease purges from the seal on the

inside of the tunnel. This should

take approximately two pumps. Do

not use more than four pumps.

Throttle Cable

Lubricate the throttle cable lightly

with grease or oil. With the engine

off, turn the handlebars to the left

and lubricate liberally as shown.

Choke and Choke Cable

Lubricate the choke slide and cables

lightly with oil or grease. Before

turning the engine off, operate the

choke intermittently to draw mois-

ture out of the choke plunger area

and reduce the possibility of the

choke becoming frozen.

+

+

+