Suzki Burgman AN400. Manual - part 78

8-34 ELECTRICAL SYSTEM

BATTERY

SPECIFICATIONS

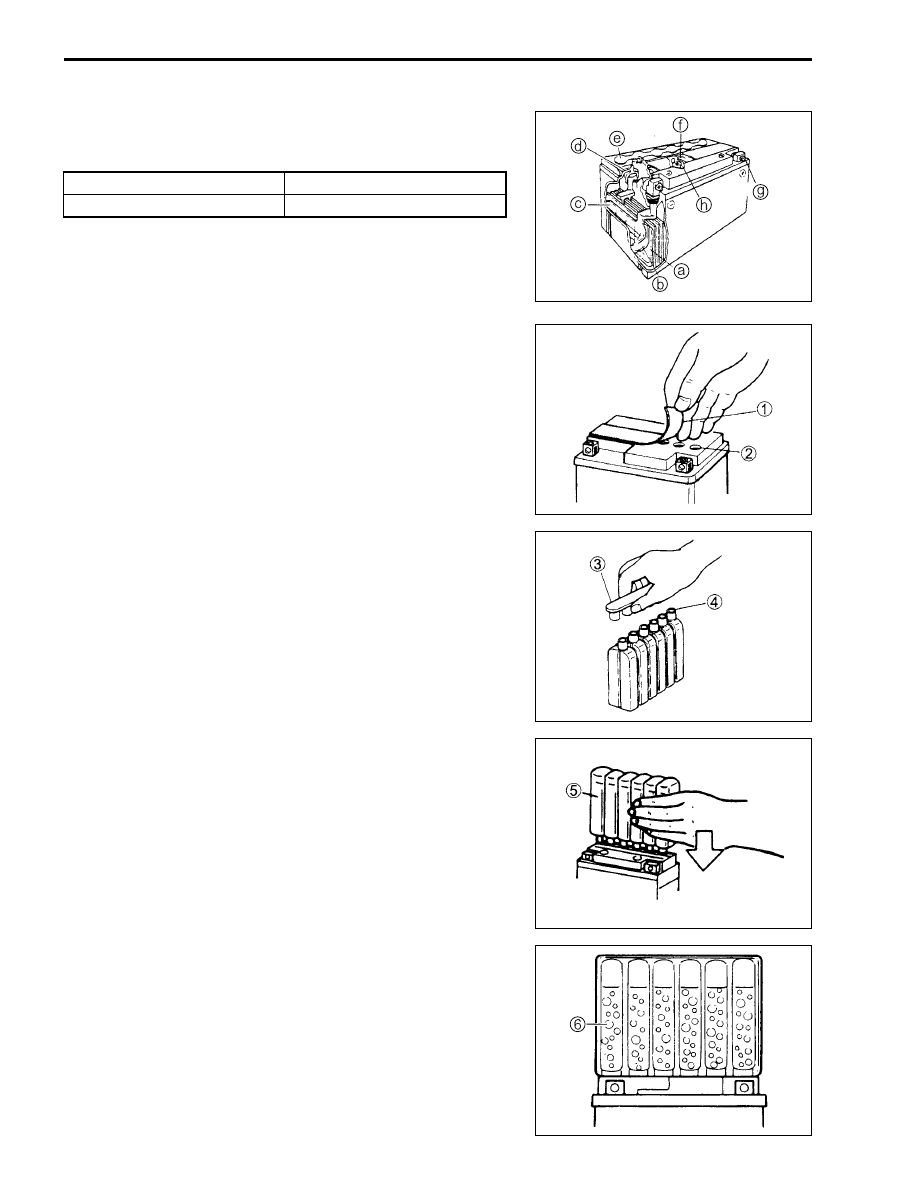

a

Anode plates

e

Stopper

b

Separator (fiberglass plate)

f

Filter

c

Cathode plates

g

Terminal

d

Upper cover breather

h

Safety valve

INITIAL CHARGING

FILLING ELECTROLYTE

• Remove the aluminum tape

1

sealing the battery electrolyte

filler holes

2

.

• Remove the caps

3

.

NOTE:

* After filling the electrolyte completely, use the removed caps

3

as the sealed caps of battery filler holes.

* Do not remove or pierce the sealed areas

4

of the electrolyte

container.

• Insert the nozzles of the electrolyte container

5

into the bat-

tery’s electrolyte filler holes, holding the container firmly so

that it does not fall. Take precaution not to allow any of the

fluid to spill.

• Make sure air bubbles

6

are coming up each electrolyte con-

tainer, and leave in this position for about more than 20 min-

utes.

Type designation

FT12A-BS

Capacity

12 V, 36 kC (10 Ah)/10 HR