Suzki Burgman AN400. Manual - part 76

8-26 ELECTRICAL SYSTEM

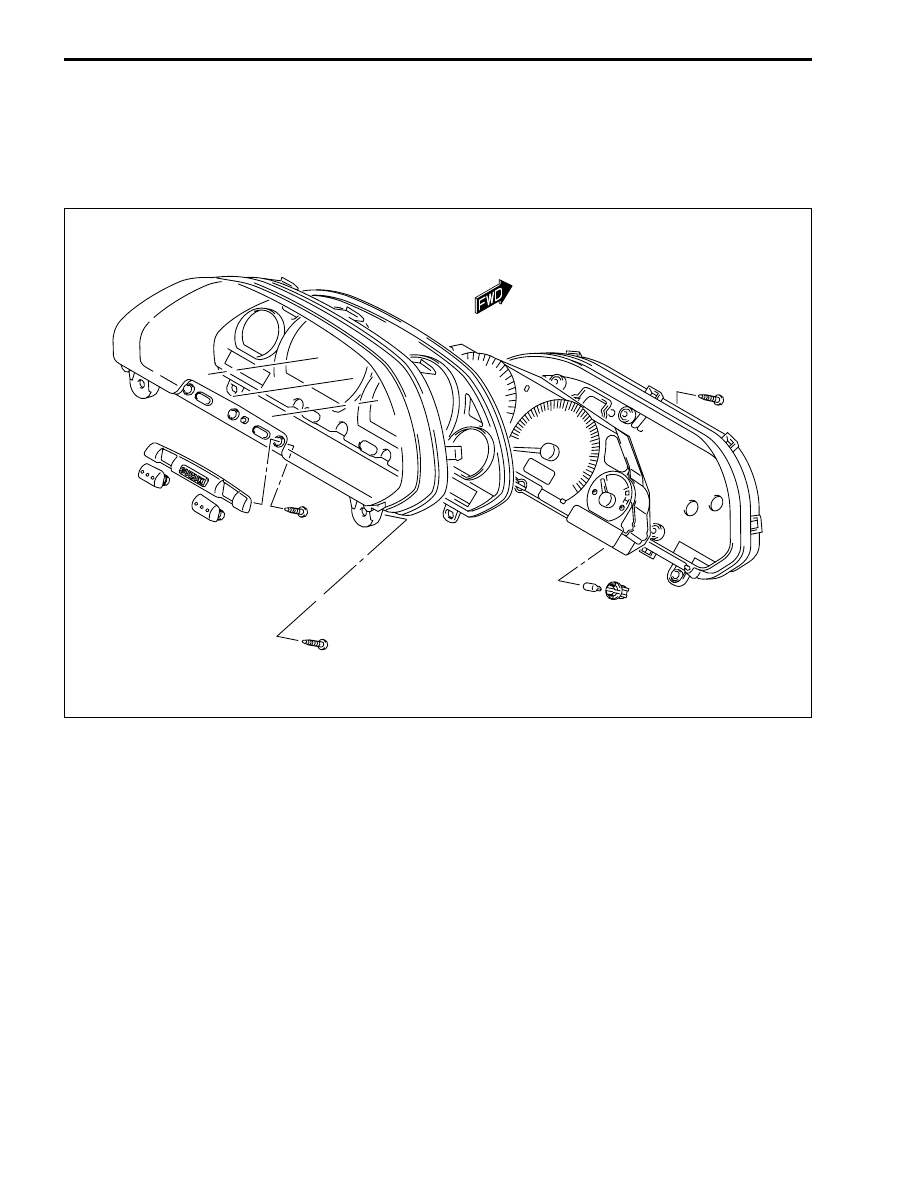

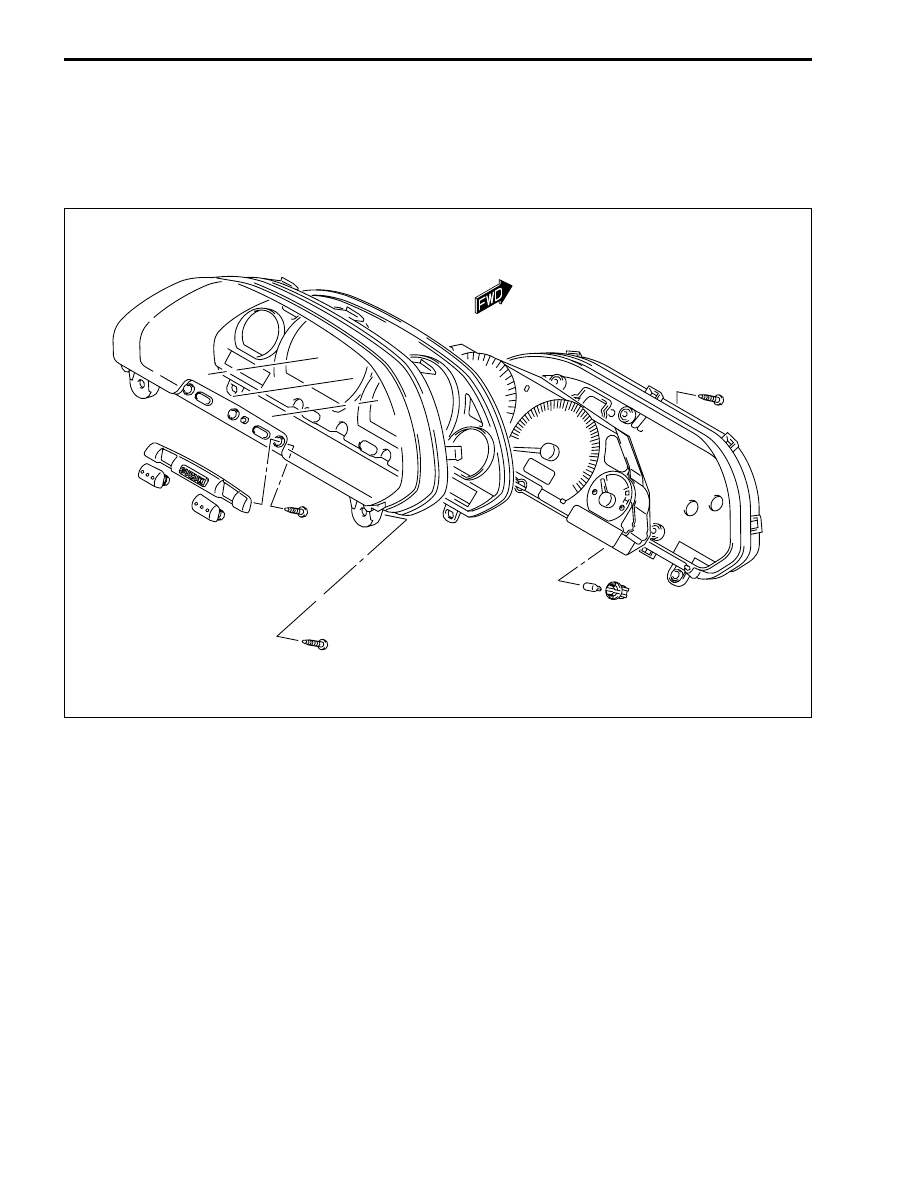

COMBINATION METER

REMOVAL AND DISASSEMBLY

• Remove the front meter panel. (

!

7-13)

• Disassembly the combination meter, as shown.

|

|

|

8-26 ELECTRICAL SYSTEM COMBINATION METER REMOVAL AND DISASSEMBLY • Remove the front meter panel. ( ! 7-13) • Disassembly the combination meter, as shown. |