Suzki Burgman AN400. Manual - part 42

5-6 FUEL SYSTEM AND THROTTLE BODY

REASSEMBLY AND INSTALLATION

• Reassemble and installation the fuel tank in the reverse order

of removal and disassembly.

• Pay attention to the following points:

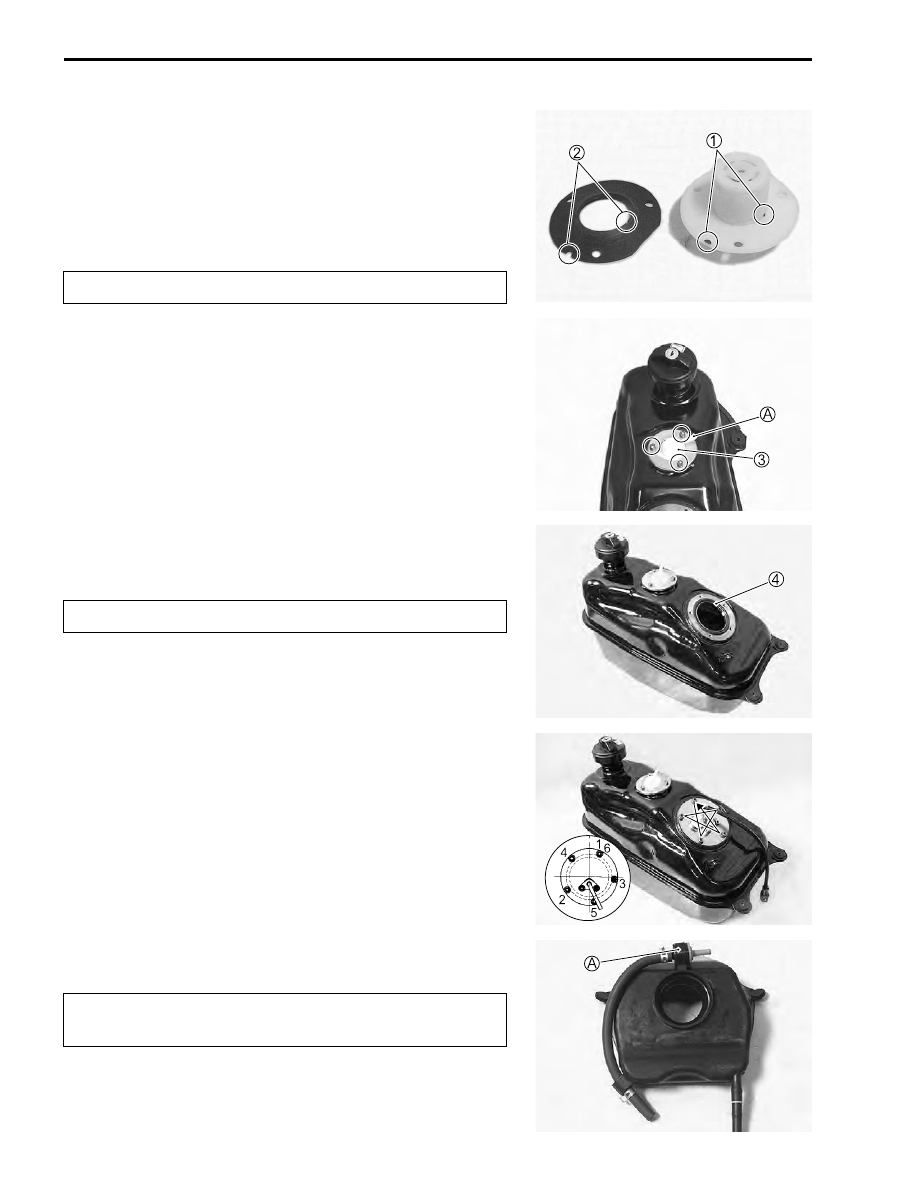

• Align the protrusion

1

of the fuel cut valve with the cutaway

2

of the gasket.

#

• Install the fuel cut valve

3

.

NOTE:

Install the fuel cut valve so that its hose fitting joint

A

faces the

right side of the vehicle.

• Tighten the fuel cut valve bolt to the specified torque.

%

Fuel cut valve bolt: 3.5 N·m (0.35 kgf-m, 2.5 lb-ft)

• Apply thin coat of the engine oil to the O-ring

4

.

• Install the O-ring to the fuel tank.

#

• When installing the fuel pump assembly, first tighten all the

fuel pump assembly mounting bolts lightly in the ascending

order of numbers, and then tighten them to the specified

torque in the above tightening order.

%

Fuel pump mounting bolt: 4.5 N·m (0.45 kgf-m, 3.3 lb-ft)

• Install the FTPC valve.

#

Replace the gasket with a new one.

Replace the O-ring with a new one.

Connect the hose to the black part

A

of the FTPC

valve.