Volkswagen Golf / Golf GTI / Golf Variant. Service manual - part 851

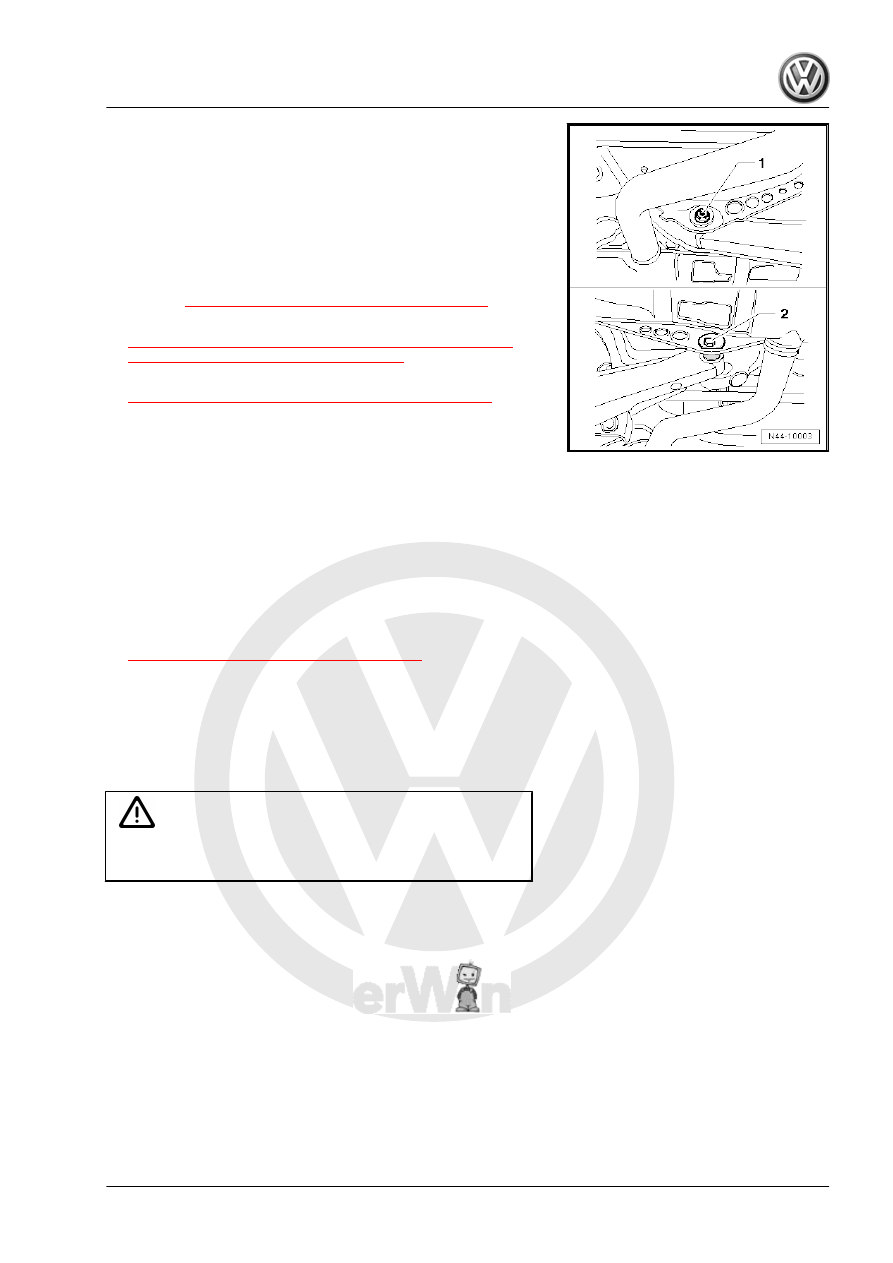

– Mark the position of the eccentric screw -2- in relation to the

subframe, for example using a felt-tip pen.

– Unscrew the nut -1- and remove the bolt -2-.

– Remove lower transverse link.

Installing

Install in reverse order of removal while noting the following:

Tightening Specifications

♦ Refer to

⇒ “5.1 Overview - Transverse Link”, page 181

♦ Refer to

⇒ “2.4 Left/Right Rear Level Control System Sensor G76 /

G77 , Removing and Installing”, page 282

♦ Refer to

⇒ “1.1 Wheel Bolt Tightening Specifications”, page 286

♦ Rear exhaust system. Refer to ⇒ Rep. Gr. 26 ; Exhaust Pipes/

Mufflers; Overview - Muffler .

• Observe the mark made for the eccentric screw -2- in relation

to the subframe.

• Only fasten the transverse link in the curb weight position.

• For vehicles with a level control system sensor, perform the

basic setting for the wheel damping electronics using the Ve‐

hicle Diagnostic Tester.

• For vehicles with a level control system sensor, perform a

headlamp basic setting. Refer to ⇒ Electrical Equipment; Rep.

Gr. 94 ; Headlamp; Headlamp, Adjusting .

– Perform an axle alignment. Refer to

⇒ “3.5 Axle Alignment Procedure”, page 302

5.5

Tie Rod, Removing and Installing

Special tools and workshop equipment required

♦ Torque Wrench 1331 5-50Nm - VAG1331-

♦ Torque Wrench 1332 40-200Nm - VAG1332-

Caution

This procedure contains mandatory replaceable parts. Refer

to component overview prior to starting procedure.

Mandatory Replacement Parts

♦ Bolt - Stabilizer Bar to Subframe

♦ Bolt- Tie Rod to Wheel Bearing Housing

♦ Bolt - Tie Rod to Subframe

♦ Nut - Tie Rod to Subframe

Removing

– Loosen the wheel bolts.

– Raise the vehicle.

– Remove the wheel.