Volkswagen Golf / Golf GTI / Golf Variant. Service manual - part 832

Tightening the Tensioning Clamp on the Smaller Diameter on the

Inner/Outer Joint

6.7

Outer CV Joint, Checking

It is necessary to disassemble the joint whenever replacing the

grease or if the ball surfaces show wear or damage.

Removing

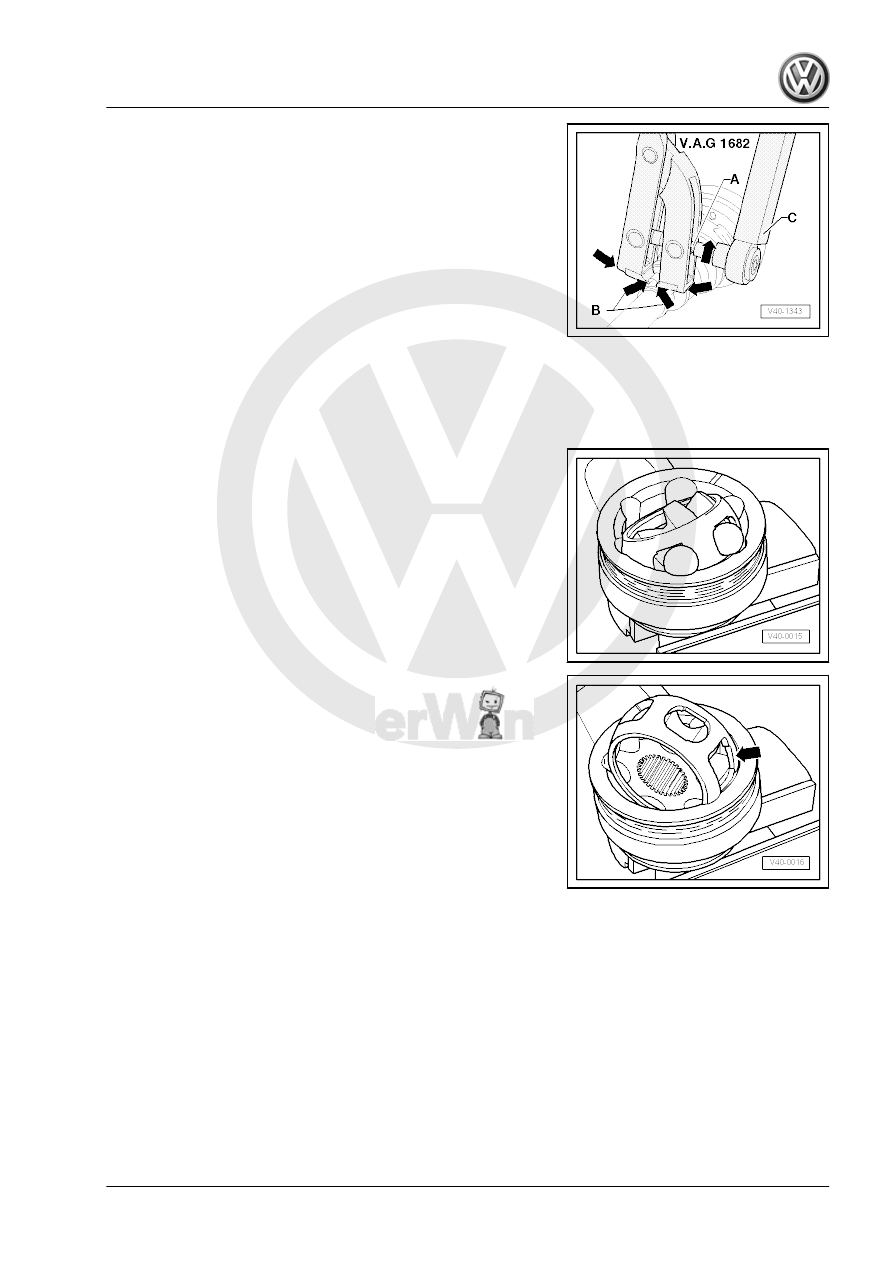

– Mark position of ball hub to ball cage and to housing before

disassembling, using electro-writer or grindstone.

– Swivel the ball hub and ball cage.

– Remove the balls one after the other.

– Turn cage until the two rectangular windows -arrow- are

aligned with the joint housing.

– Lift out cage with hub.