Volkswagen Golf / Golf GTI / Golf Variant. Service manual - part 797

Removing

– Place sufficient lint-free cloths in the area of the engine and

transmission.

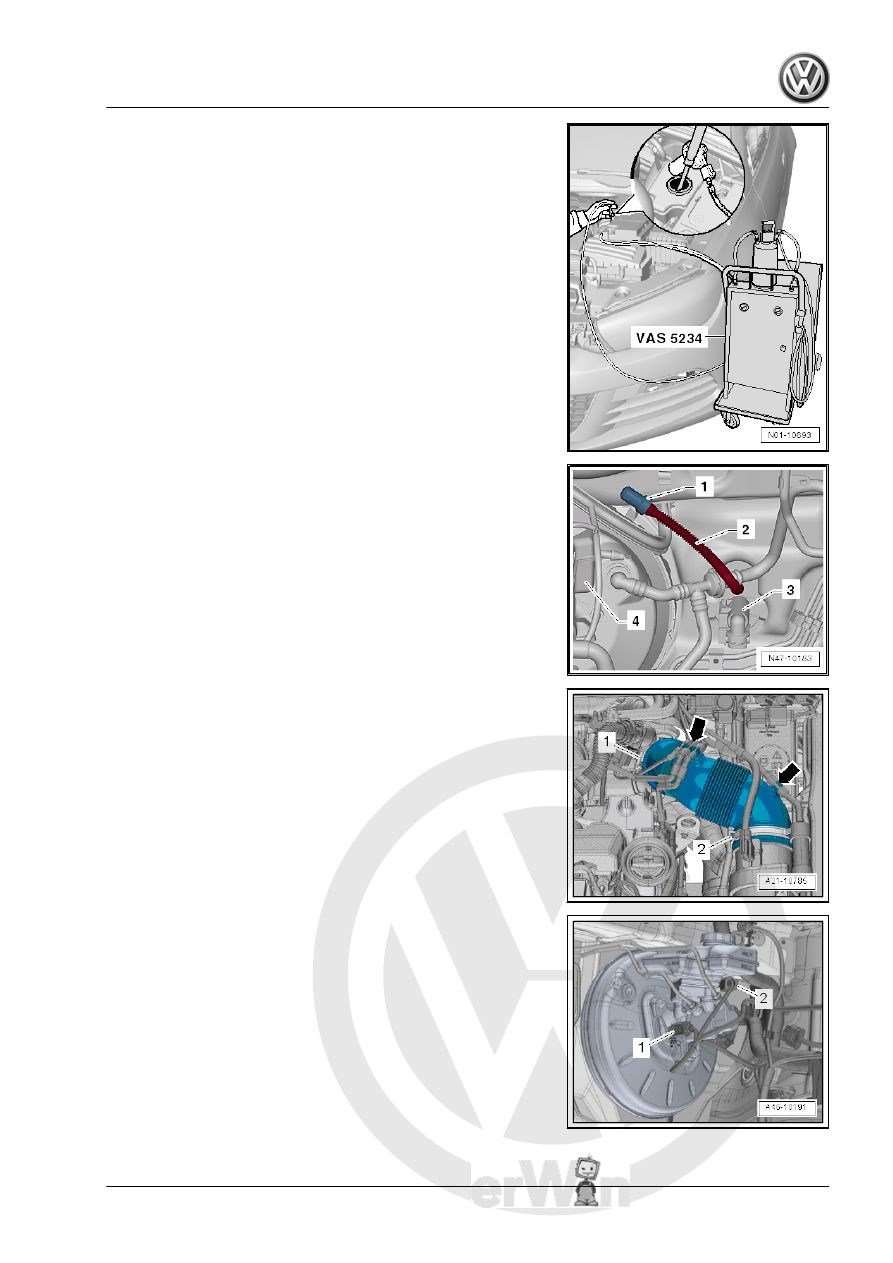

– Extract as much brake fluid as possible from the brake fluid

reservoir with the Brake Charger/Bleeder Unit - VAS5234- .

Vehicles with Manual Transmission

– Remove the supply hose -2- for the clutch master cylinder

-3- from the brake fluid reservoir -4-.

– Seal the supply hose -2- for the clutch master cylinder -3- using

Sealing Tool - T10249- -1- or Engine Bung Set - VAS6122- .

– Tie up the return hose -2-.

Vehicles with Diesel Engine and 2.0L Gasoline Engine

– Remove the engine cover. Refer to ⇒ Engine Mechanical,

Fuel Injection and Ignition; Rep. Gr. 10 ; Engine Cover; Engine

Cover, Removing and Installing . or ⇒ Engine Mechanical,

Fuel Injection and Glow Plug; Rep. Gr. 10 ; Engine Cover;

Engine Cover, Removing and Installing

– Loosen hose clamps and remove the air guide hose and air

filter housing. Refer to ⇒ Engine Mechanical, Fuel Injection

and Ignition; Rep. Gr. 24 ; Air Filter; Air Filter Housing, Re‐

moving and Installing .

Continuation for All Vehicles

– Release the connection -2- for the Brake Fluid Level Warning

Switch - F34- and remove.