Volkswagen Golf / Golf GTI / Golf Variant. Service manual - part 775

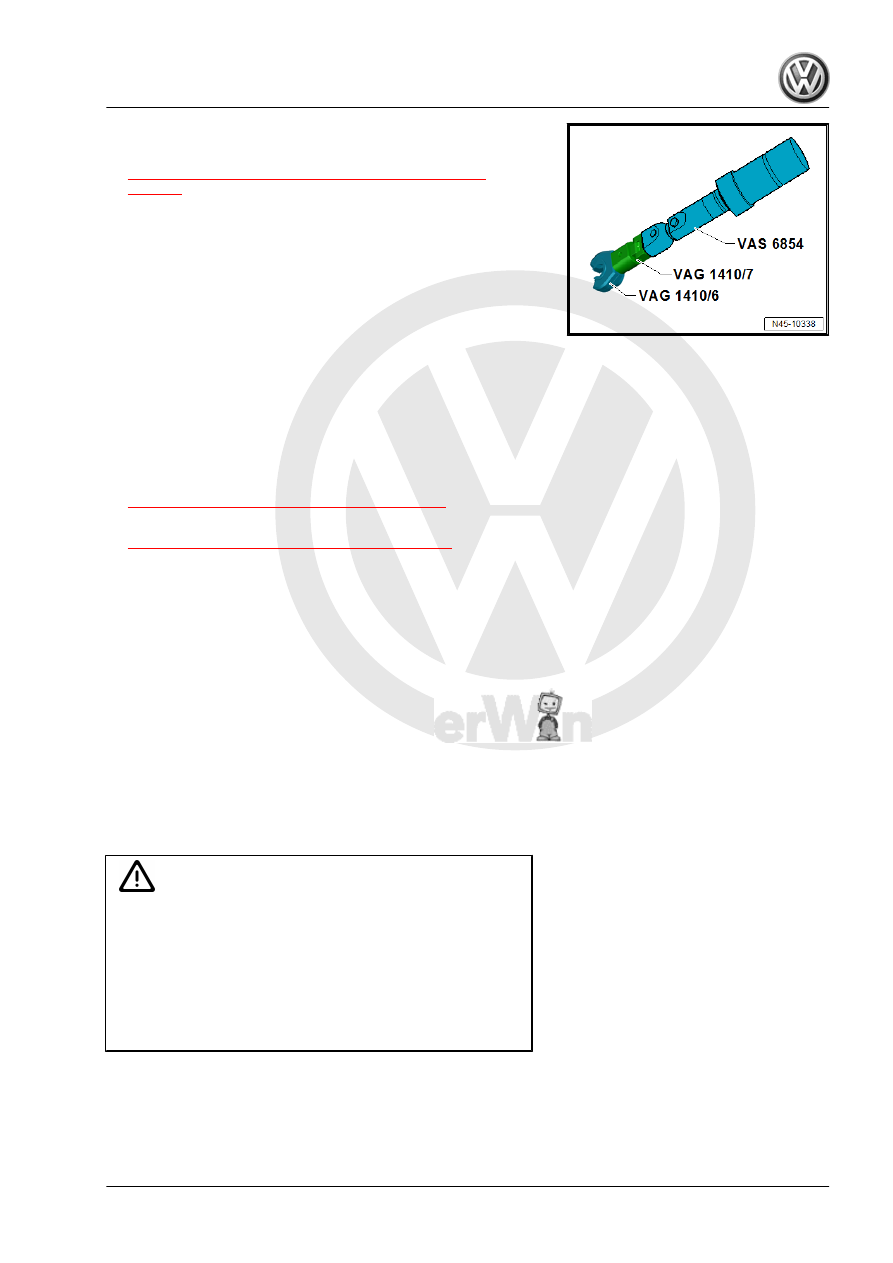

Special Tool Assembly for Tightening the Brake Lines

♦ Refer to

⇒ “3.1 Overview - Control Module and Hydraulic Unit”,

♦ Battery. Refer to ⇒ Electrical Equipment; Rep. Gr. 27 ; Bat‐

tery; Overview - Battery .

♦ Noise insulation bolts. Refer to ⇒ Body Exterior; Rep. Gr. 66 ;

Noise Insulation; Overview - Noise Insulation .

♦ Front exhaust pipe. Refer to ⇒ Rep. Gr. 26 ; Exhaust Pipes/

Mufflers; Front Exhaust Pipe, Removing and Installing .

♦ Pendulum support. Refer to ⇒ Engine Mechanical, Fuel In‐

jection and Ignition; Rep. Gr. 10 ; Subframe Mount; Overview

- Subframe Mount .

♦ Driveshaft. Refer to ⇒ Suspension, Wheels, Steering; Rep.

Gr. 40 ; Drive Axle; Overview - Drive Axle .

♦ Lower control arm. Refer to ⇒ Suspension, Wheels, Steering;

Rep. Gr. 40 ; Lower Control Arm and Ball Joint; Overview -

Lower Control Arm and Ball Joint .

♦ Front bleeder valve. Refer to

⇒ “1.1 Overview - Front Brake Caliper”, page 97

♦ Rear bleeder valves. Refer to

⇒ “2.1 Overview - Rear Brake Caliper”, page 100

3.3

Control Module, Separating from Hy‐

draulic Unit

Special tools and workshop equipment required

♦ ESD Work Surface - VAS6613-

♦ TORX

®

Insert T25

♦ If the ABS Control Module - J104- is faulty, then the control

module is to be separated from the ABS Hydraulic Unit - N55-

and only the control module replaced.

♦ If the ABS Hydraulic Unit - N55- is faulty, then replace the ABS

Hydraulic Unit - N55- together with the ABS Control Module -

J104- .

♦ To separate the ABS Control Module - J104- and the ABS Hy‐

draulic Unit - N55- the unit must be removed.

WARNING

♦ The return flow pump may also not be separated from the

ABS Hydraulic Unit - N55- .

♦ The circuit board is exposed when the ABS Control Mod‐

ule - J104- is removed.

♦ Protect the ABS Control Module - J104- from moisture and

dirt particles from getting inside.

♦ Avoid build-up of static electricity!

This build-up of static electricity can lead to malfunctions when

contacting electrical components.

– Touch a grounded object, before working on electrical equip‐

ment ESD Work Surface - VAS6613- . Do not touch directly

on the connector terminals or the electrical components.