Volkswagen Golf / Golf GTI / Golf Variant. Service manual - part 690

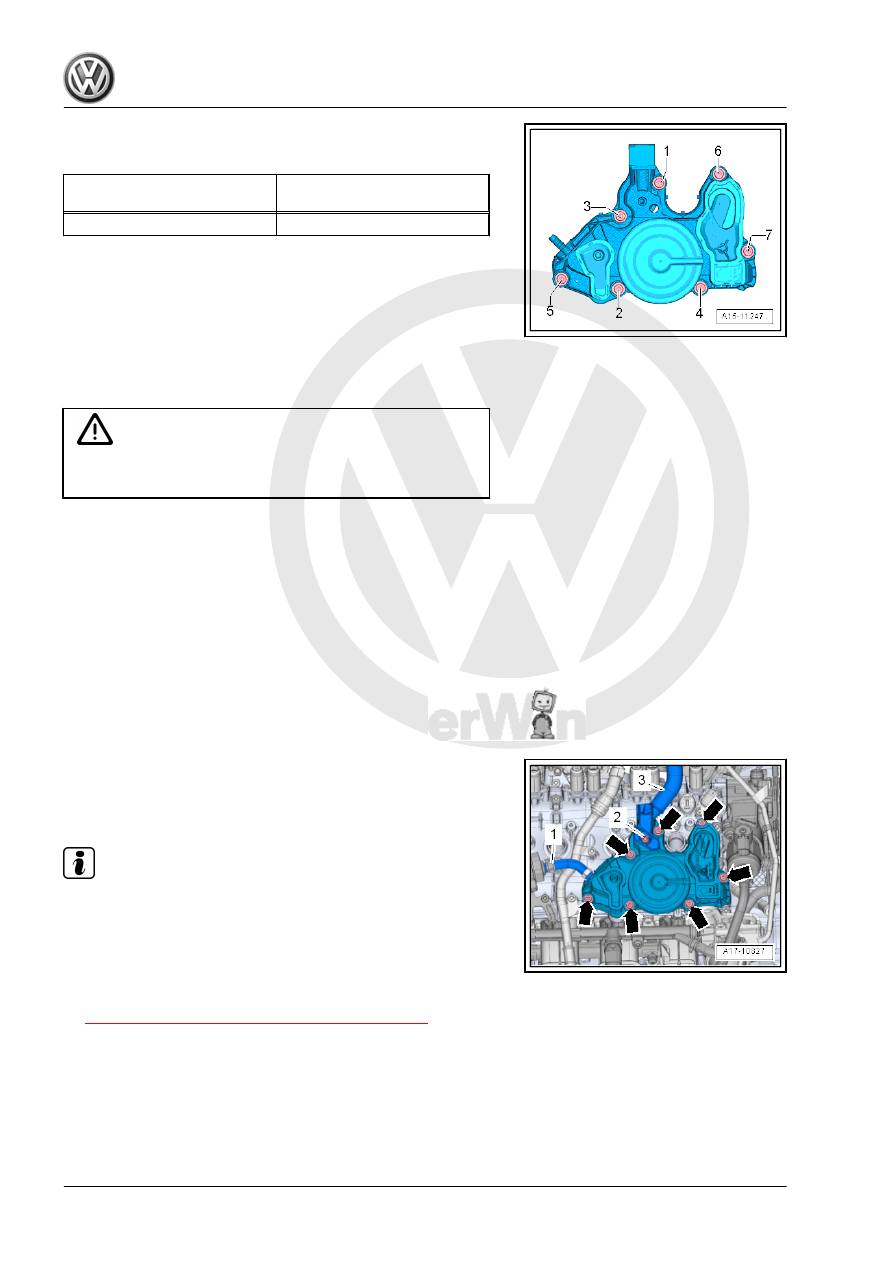

Oil Separator - Tightening Sequence

– Tighten the bolts in the sequence -1 through 7-.

Bolts

Tightening Sequence and Tor‐

que Specification

-1 through 7-

9 Nm.

3.2

Oil Separator, Removing and Installing

Removing

Caution

This procedure contains mandatory replaceable parts. Refer

to component overview prior to starting procedure.

Mandatory Replacement Parts

♦ Seal - Oil Separator

♦ Seals - Oil Separator to Crankcase Hose

– Disconnect the ignition coil sensors connectors and remove

them from the ignition coils at the same time.

– Remove the ignition coils bolts “3, 4”, and remove the ignition

coils.

– Loosen the hose clamp -1- and remove the hose from EVAP

Canister Purge Regulator Valve 1 - N80- .

– Remove bolt -2- and then remove crankcase ventilation hose

-3- from oil separator.

– Remove the bolts -arrows- and the oil separator.

Installing

Install in reverse order of removal. Note the following:

Note

♦

Always replace gasket and seals.

♦

Secure hose connections with standard production clamps.

Refer to the Parts Catalog.

Tightening Specifications

♦ Refer to