Volkswagen Golf / Golf GTI / Golf Variant. Service manual - part 678

Note

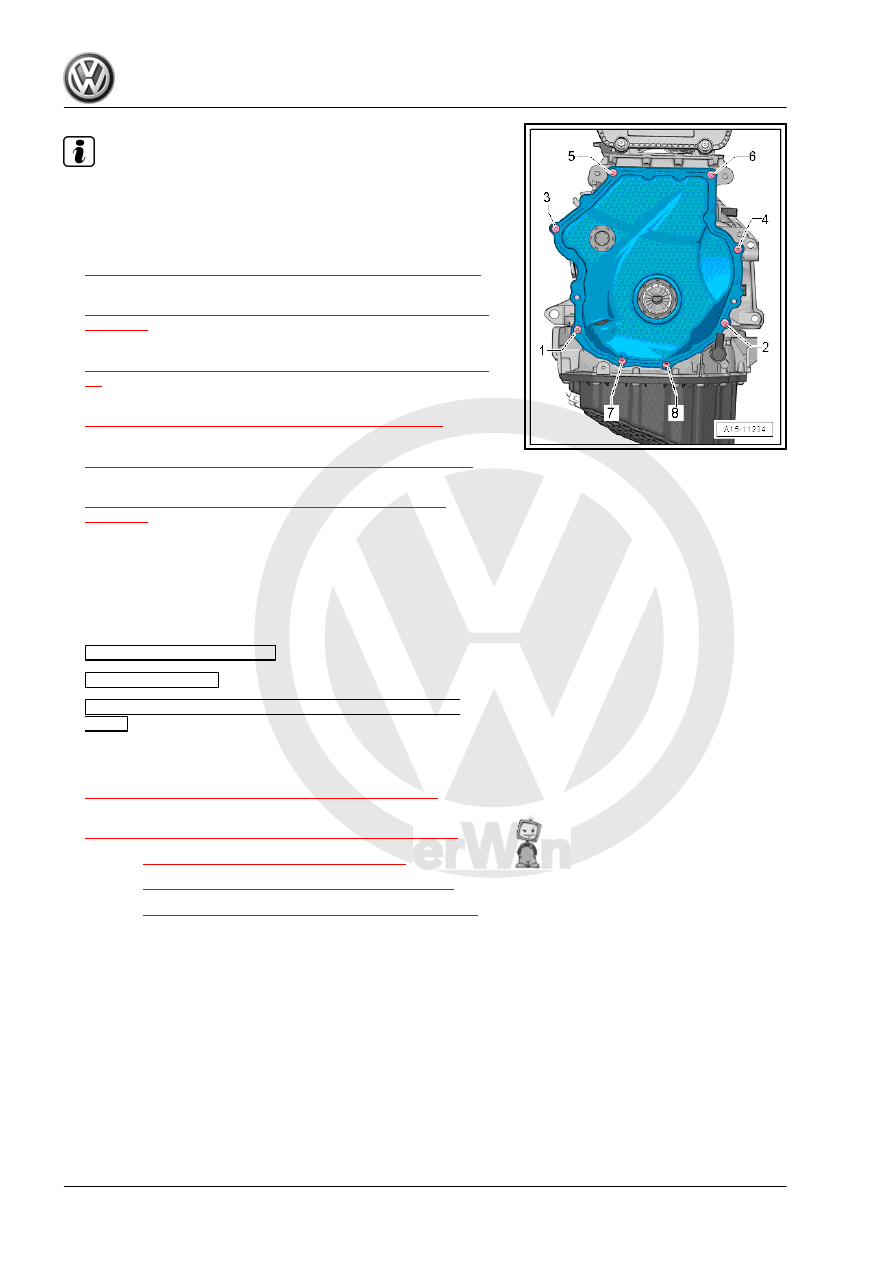

Tighten the bolts -1 and 4- with an additional turn after installing

the vibration damper. The bolts must be removed again to install

the vibration damper.

– Install the vibration damper. Refer to

⇒ “1.4 Vibration Damper, Removing and Installing”, page 47

– Install the upper timing chain cover. Refer to

⇒ “2.2.1 Upper Timing Chain Cover, Removing and Installing”,

– Install the ribbed belt tensioning damper. Refer to

⇒ “1.3 Ribbed Belt Tensioner, Removing and Installing”, page

– Install the ribbed belt. Refer to

⇒ “1.2 Ribbed Belt, Removing and Installing”, page 46

.

– Install the vacuum pump. Refer to

⇒ “1.4 Vacuum Pump, Removing and Installing”, page 100

– Install the high pressure pump. Refer to

⇒ “7.2 High Pressure Pump, Removing and Installing”,

The rest of the installation is performed in reverse order of re‐

moval, noting the following:

– After performing work on the chain drive the adaptation value

in the Engine Control Module (ECM) must be adapted. To do

this turn on the ignition and select the following menu items on

the Vehicle Diagnostic Tester :

♦

01 - Engine Electronics

♦

Guided Functions

♦

01 - Adaptation After Repair Work on the Chain

Drive

Tightening Specifications

♦ Refer to

⇒ “3.1 Overview - Camshaft Timing Chain”, page 114

.

♦ Refer to

⇒ “3.2 Overview - Balance Shaft Drive Chain”, page 116

♦ Refer to

⇒ “4.1 Overview - Valvetrain”, page 133

♦ Refer to

⇒ “3.1 Overview - Air Filter Housing”, page 293

.

♦ Refer to

⇒ “7.1 Overview - High Pressure Pump”, page 325

♦ Refer to ⇒ Body Exterior; Rep. Gr. 66 ; Noise Insulation;

Overview - Noise Insulation .

4.2.2

Camshaft, Removing and Installing, En‐

gine Codes CNTA, CXCA, CXCB

Special tools and workshop equipment required

♦ Central Valve Assembly Tool - T10352-

♦ Counterhold - Vibration Damper - T10355-

♦ Chain Tensioner Lever - T40243-

♦ Tensioner Locking Tool - T40267-