Volkswagen Golf / Golf GTI / Golf Variant. Service manual - part 664

14 - O-Ring

❑ Coat with coolant

❑ Replace after removing

15 - Connection

❑ For coolant hose

16 - Bolt

❑ 9 Nm

17 - Mount

❑ For engine cover

18 - Engine Lifting Eye

19 - Bolt

❑ 8 Nm + 90° turn

❑ Replace after removing

20 - Partition Plate

21 - Ball Pin

❑ For engine cover

22 - Engine Lifting Eye

23 - Bolt

❑ 8 Nm + 90° turn

❑ Replace after removing

24 - Alignment Pin

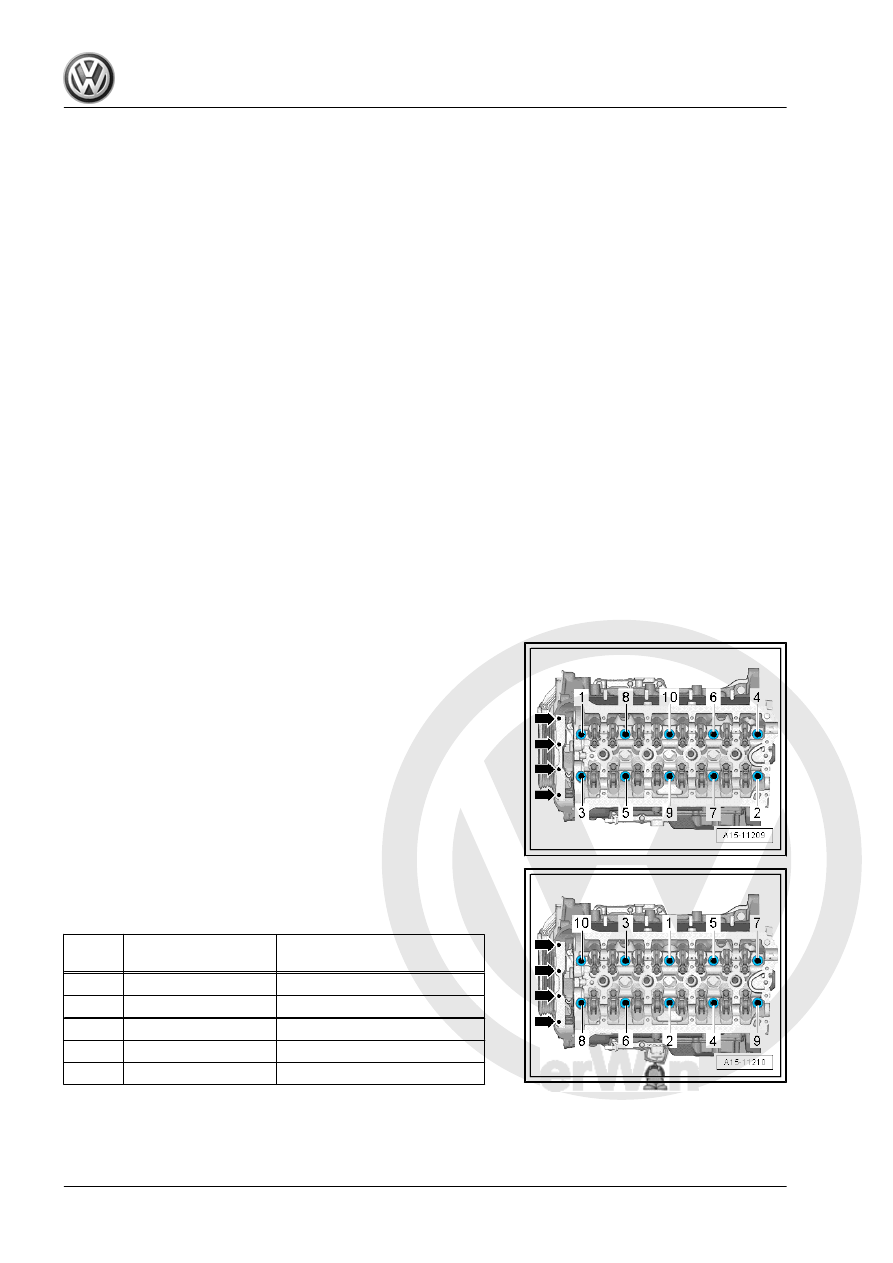

Loosening Cylinder Head

– Remove the bolts -arrows-.

– Loosen the cylinder head bolts in the sequence -1 to 10-.

Cylinder Head Tightening Sequence

– Tighten the cylinder head bolts in the sequence -1 to 10- as

follows.

Step

Bolts

Tightening Specification/Addi‐

tional Turn

1.

-1- through -10-

40 Nm

2.

-1- through -10-

Turn an additional 90°.

3.

-1- through -10-

Turn an additional 90°.

4.

Bolts -arrows-

4 Nm

5.

Bolts -arrows-

Turn an additional 90°.