Volkswagen Golf / Golf GTI / Golf Variant. Service manual - part 661

Tightening Specifications

♦ Refer to

⇒ “5.1 Overview - Piston and Connecting Rod”, page 77

5.3

Pistons and Cylinder Bore, Checking

⇒ “5.3.1 Pistons and Cylinder Bore, Checking, Engine Codes

CXBA, CXBB, CNSA and CNSB”, page 80

⇒ “5.3.2 Piston and Cylinder Bore, Checking, Engine Codes

5.3.1

Pistons and Cylinder Bore, Checking,

Engine Codes CXBA, CXBB, CNSA and

CNSB

Pistons, Checking

Special tools and workshop equipment required

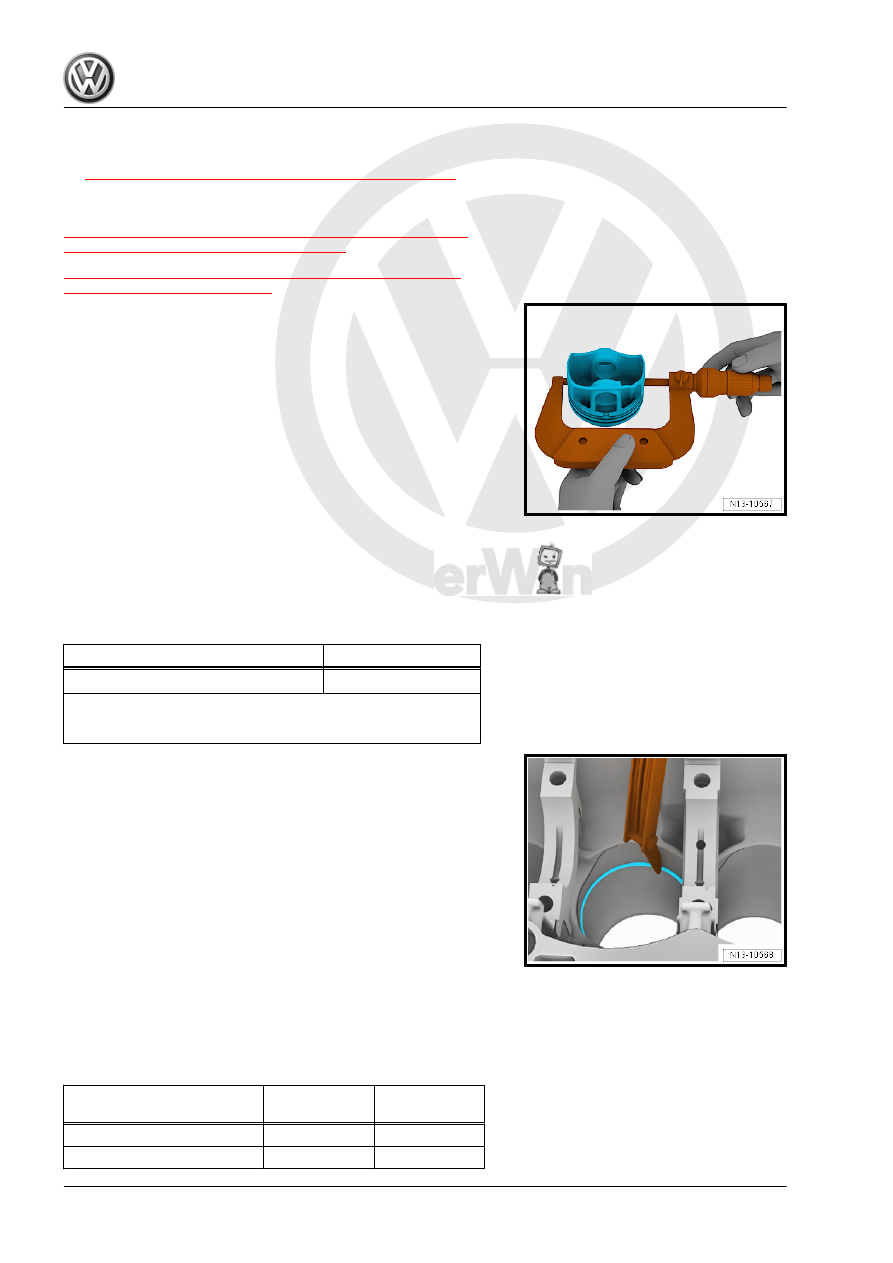

♦ Outside Micrometer - 75-100mm - VAS6071-

– Measure approximately 15 mm in from the lower edge at a 90°

angle to the piston pin axis using a micrometer.

♦ Deviation from specified size: maximum 0.04 mm

Basic Dimension

Piston Diameter

in mm

82.465

1)

•

1)

Measurements without graphite coating (thickness = 0.02

mm). The graphite coating wears off.

Checking Piston Ring Gap

Special tools and workshop equipment required

♦ Feeler Gauge

– Push piston ring squarely from above down to approximately

15 mm from bottom end of cylinder. To do this use a piston

without rings.

Piston Ring

Dimensions in mm

New

Wear Limit

Compression ring

0.20 to 0.40

0.80

Oil scraping ring

0.25 to 0.50

0.80