Volkswagen Golf / Golf GTI / Golf Variant. Service manual - part 627

– Remove the Transmission Support - 3282- from the transmis‐

sion.

– Replace all the bolts from the left subframe mount.

– Install all the new bolt first hand-tight.

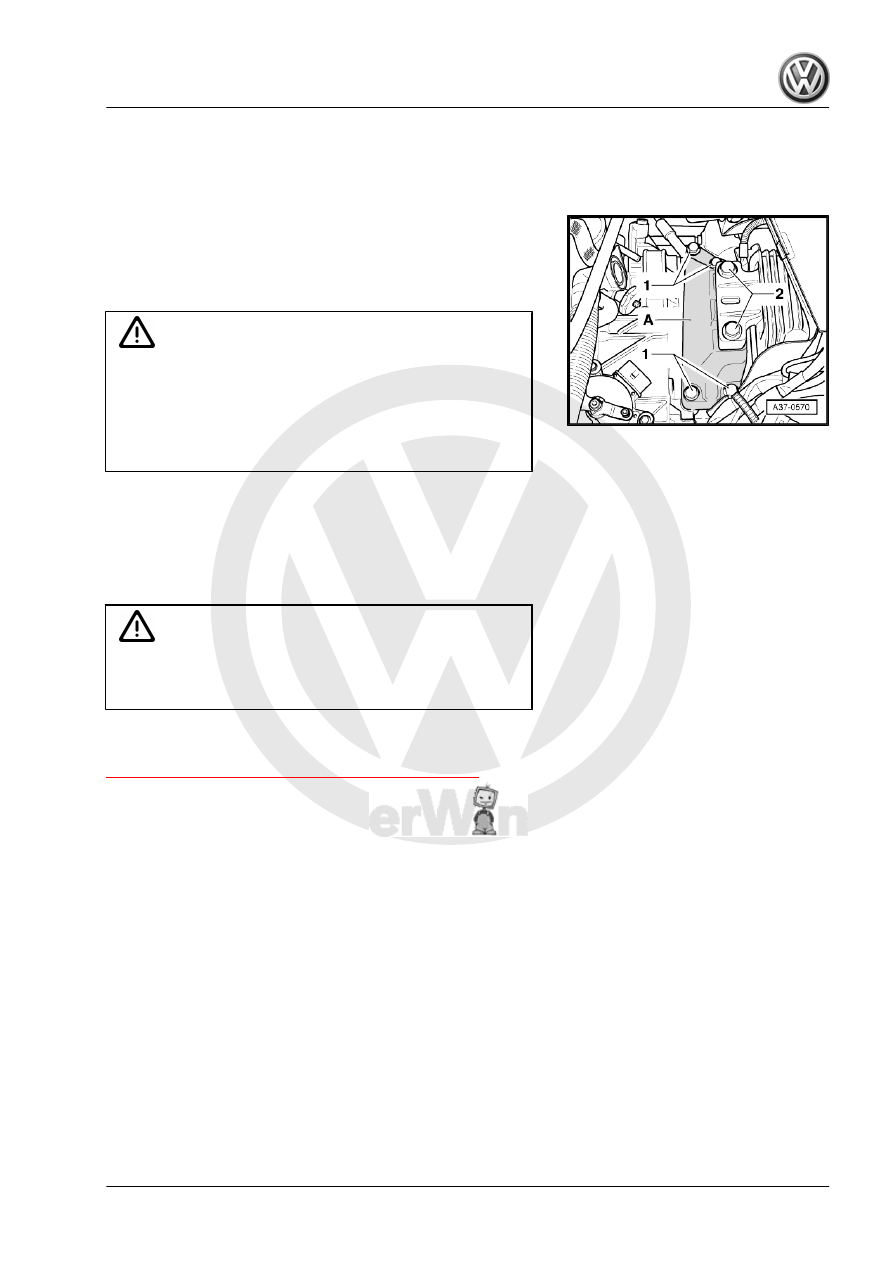

First tighten the bolts -1- when installing the transmission bracket

-A-.

– Align the engine/transmission in its installed position. Lift until

the transmission bracket is touching the transmission mount

completely.

Caution

Risk of damaging threads in transmission bracket by inserting

bolts crooked.

♦ Before installing bolts -2-, transmission bracket and trans‐

mission mount support arm must be absolutely parallel to

each other. If necessary, lift the back of the transmission

with Engine and Transmission Jack .

Adjust the »old fit« between both bolts using a screwdriver when

tightening the transmission bracket to the transmission mount

bolts -2-.

– Check the subframe mount adjustment. If required, adjust.

Refer to ⇒ Engine Mechanical, Fuel Injection and Ignition;

Rep. Gr. 10 ; Subframe Mount; Subframe Mount, Adjusting .

WARNING

Only remove Engine Support Bridge - 10-222A- when all the

left and right subframe mount bolts are tightened to the tight‐

ening specification.

Tightening specification of the transmission on the engine and the

left subframe mount. Refer to

⇒ “3.3 Transmission Tightening Specifications”, page 66

– Install the pendulum support. Refer to ⇒ Engine Mechanical,

Fuel Injection and Ignition; Rep. Gr. 10 ; Subframe Mount;

Overview - Subframe Mount .

– Install the drive axles. Refer to ⇒ Suspension, Wheels, Steer‐

ing; Rep. Gr. 40 ; Drive Axle; Drive Axle, Removing and

Installing .

– Install the heat shield over the right drive axle, if removed. Re‐

fer to ⇒ Suspension, Wheels, Steering; Rep. Gr. 40 ; Drive

Axle; Drive Axle Heat Shield, Removing and Installing .

– Align the exhaust system free of tension. Refer to ⇒ Engine

Mechanical, Fuel Injection and Ignition; Rep. Gr. 26 ; Exhaust

Pipes/Mufflers; Exhaust System, Installing without Tension .

– Install starter. Refer to ⇒ Electrical Equipment; Rep. Gr. 27 ;

Starter; Starter, Removing and Installing .