Volkswagen Golf / Golf GTI / Golf Variant. Service manual - part 623

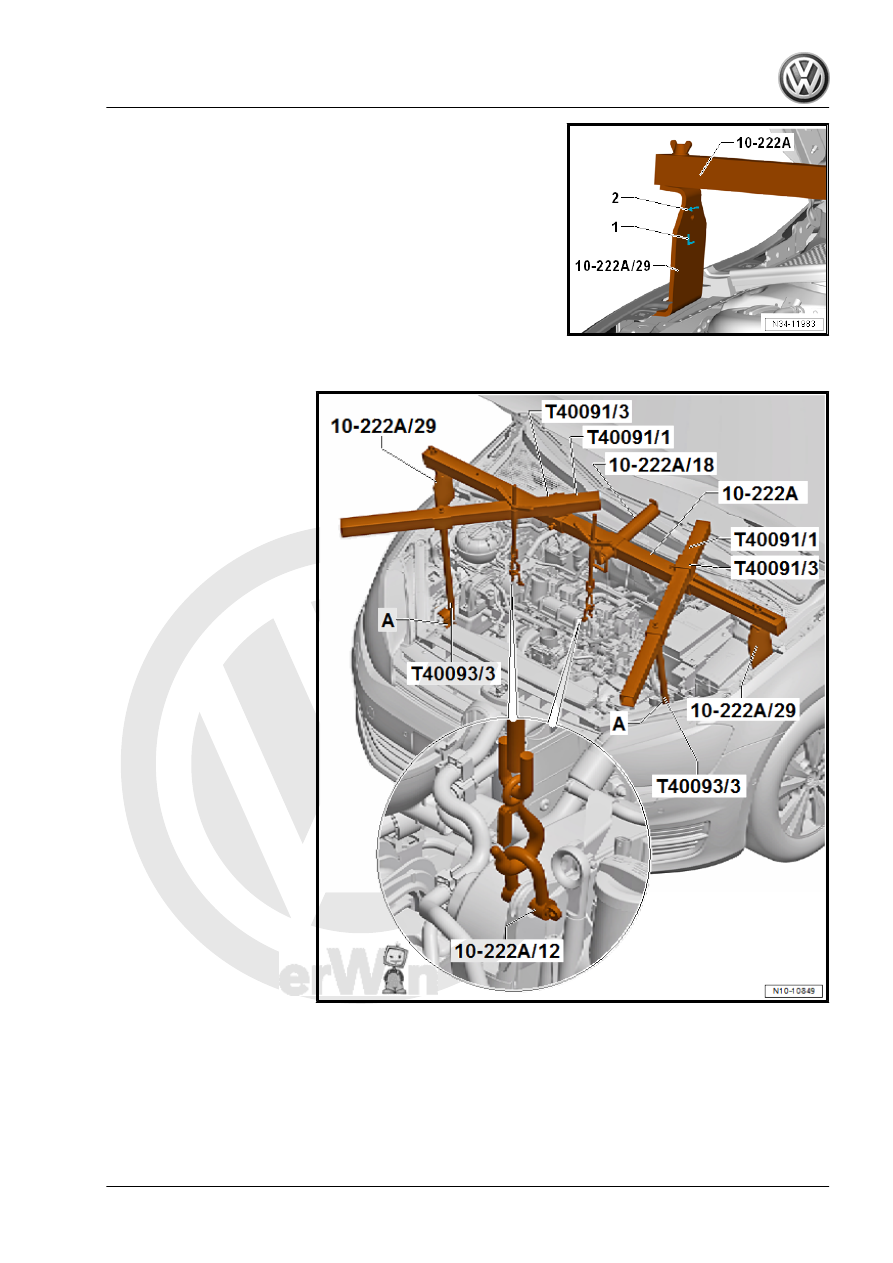

• The arrow -2- on the Engine Support Bridge - Engine Support

29 - 10-222A/29- always points in the direction of travel.

• The Engine Support Bridge - Engine Support 29 - 10-222A/29-

on the load-bearing components of the fender bolting edge.

Assemble the Engine Support Bridge - 10-222A- as follows:

– Slide the Engine Support Bridge - Engine Support 18 -

10-222A/18- and two Engine Support - Basic Set Movable

Joint - T40091/3- onto the Engine Support Bridge - 10-222A- .

– Install the Square Pipe - T40091/1- in the Engine Support -

Basic Set - Movable Joint - T40091/3- .

– Push the Engine Support Bridge - Spindle - 10 - 222 A /11- on

the square pipe -T40091/1-