Volkswagen Golf / Golf GTI / Golf Variant. Service manual - part 598

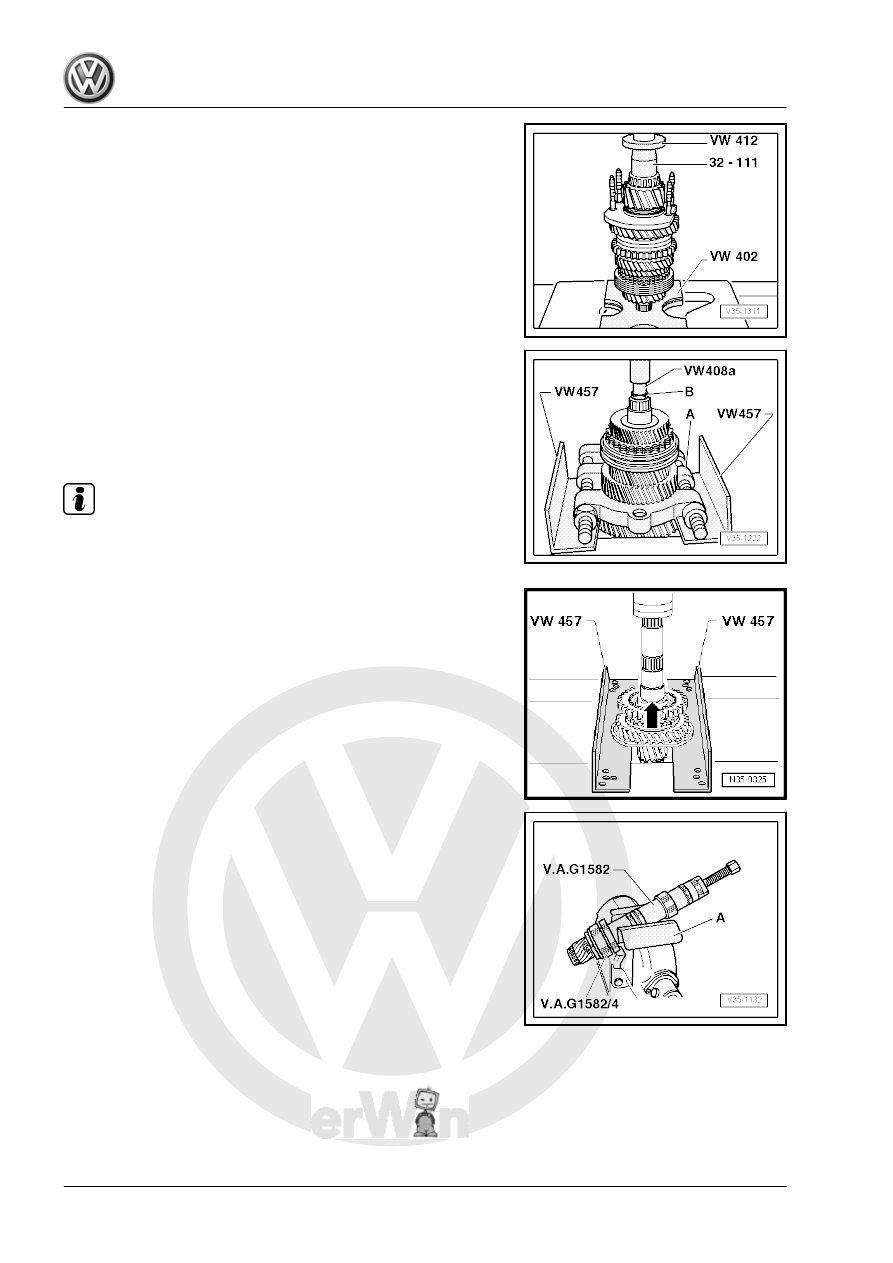

Installing the Inner Race/Small Tapered Roller Bearing

Removing the 3rd/4th Gear Synchronizer Hub/Locking Collar,

2nd Gear Wheel, 3rd and 4th Gear with Output Shaft Needle

Bearing Sleeve

A - Puller - Quick Action Separating Tool - 22-115mm - Kukko

17/2- , for example.

B - M10 x 20, 17 mm Hex Bolt

Note

Support the separating tool so that the 1st/2nd gear locking collar

does not come off as well.

Removing the Locking Collar with the Synchronizer Hub and

Bearing Mount

– Remove the locking ring -arrow- beforehand.

Removing the Inner Race/Large Tapered Roller Bearing

-A- vise protectors

– Before installing puller, insert a M10 x 20 bolt into the hole in

the output shaft.