Volkswagen Golf / Golf GTI / Golf Variant. Service manual - part 587

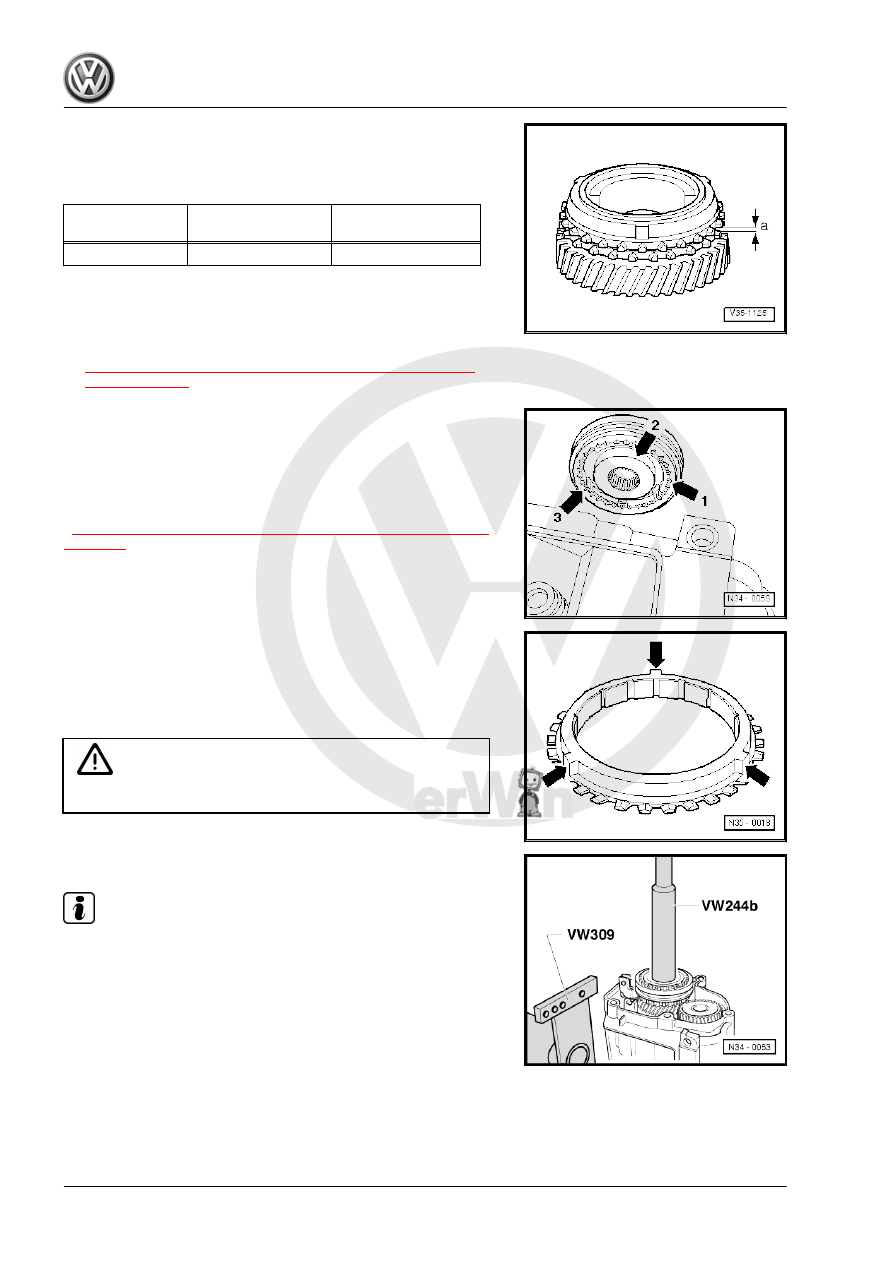

Checking 5th Gear Synchronizer Ring

– Before re-installing the gear wheel and the 5th gear synchron‐

izer ring push the synchronizer ring onto the taper of the drive

gear. Measure the gap dimension -a- with a feeler gauge.

Gap Dimension

-a-

Installation Dimen‐

sion

Wear Limit

5th Gear

1.1 to 1.7 mm

0.5 mm

– Install 5th gear wheel with needle bearing.

– Place the 5th gear synchronizer ring onto the selector gear.

– If disassembled, assemble the 5th gear synchronizer hub/

locking collar before installing. Refer to

⇒ Fig. ““5th Gear Locking Collar/Synchronizer Hub Assem‐

.

Installed Position of 5th Gear Synchronizer Hub/Locking Collar

The pointed teeth on the locking collar -arrow 1- and the high col‐

lar on the synchronizer hub -arrow 2- face the transmission hous‐

ing.

The notches -arrow 3- on the synchronizer hub must line up with

the cast locking pieces on the synchronizer ring

⇒ Fig. ““5th Gear Synchronizer Ring with Cast Locking Pieces”“ ,

lower).

5th Gear Synchronizer Ring with Cast Locking Pieces

– Cover all openings with a cloth to prevent foreign objects from

getting into the transmission.

– To install, heat the 5th gear synchronizer hub to approximately

100 °C (212 °F) with the Inductive Heater - VAS6414- .

WARNING

Wear safety gloves.

– Install the 5th gear synchronizer hub

Note

Make sure there is enough clearance when installing the syn‐

chronizer ring.