Volkswagen Golf / Golf GTI / Golf Variant. Service manual - part 513

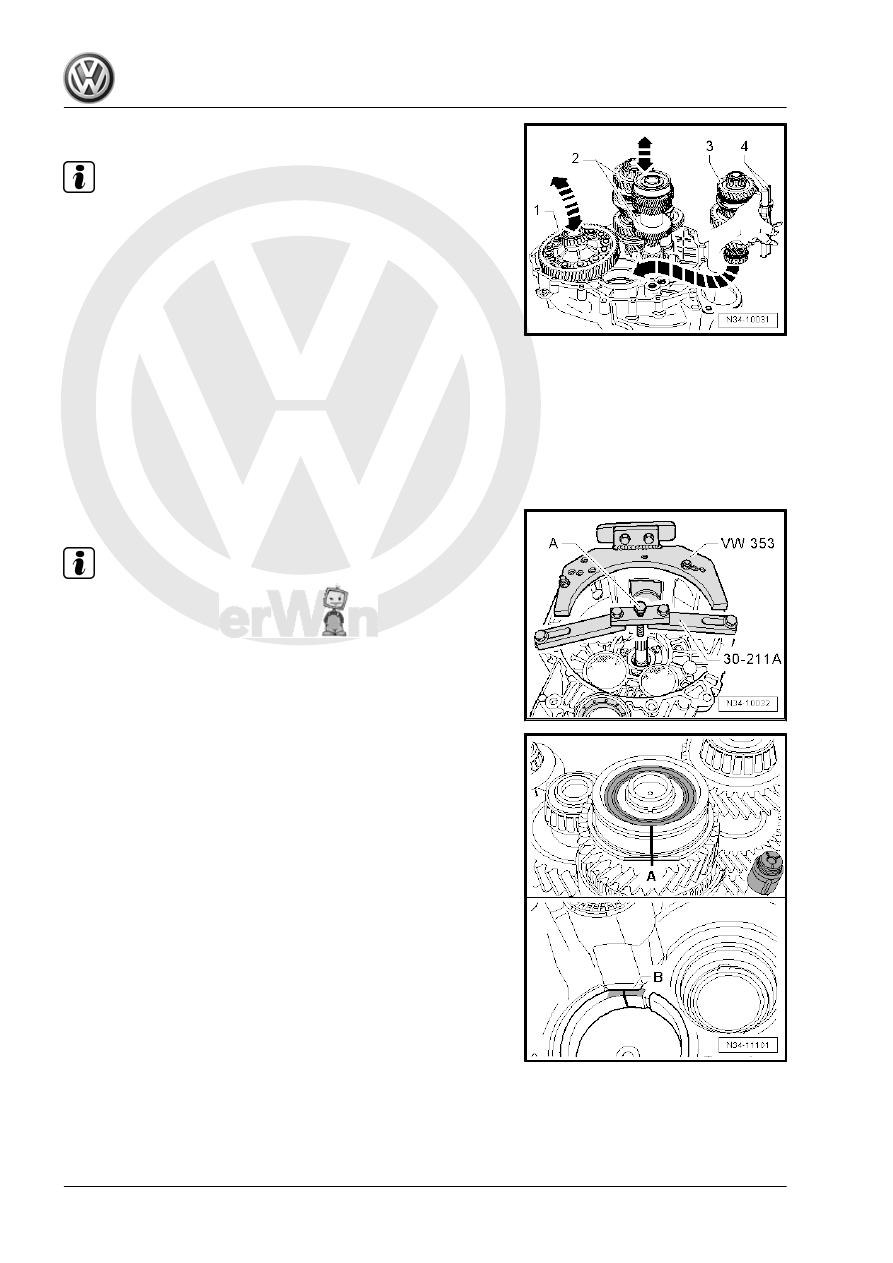

– Then install the differential -1-.

Note

A second technician is needed to help install the shafts into the

clutch housing.

– Hold 1st through 4th gear output shaft -3- with the shift lever

rods -4- in the right hand as illustrated.

– Lift the differential slightly with your left hand.

– Have the second technician lift the input shaft, the 5th/6th gear

output shaft -2- together with the reverse shaft slightly at the

same time.

– Install the 1st through 4th gear output shaft in direction of

-arrow-.

• Places of input shaft, output shafts and final drive gear/differ‐

ential must engage.

– Place the shafts and the differential in their bearing seats with

a second technician.

– Secure the -30-211A- for the input shaft to the clutch housing.

Note

The clutch housing is shown in the illustration rotated 180°.

– Install the bolt -A- just far enough until the input shaft starts to

lift.

The Grooved Ball Bearing/Input Shaft Only Fits In One Position

In the Transmission Housing.

There is a flattened area on the grooved ball bearing and the

bearing mount.

• The flattened sides -A- on the grooved ball bearing and on the

bearing mount -B- must align in the transmission housing.

– Mark this flat side with color.

– Transfer the markings to the upper area of the grooved ball

bearing and to the upper area of the transmission housing

bearing mount (⇒ next figure).

– Heat the transmission housing in the area near the bearing

seat for the grooved ball bearing/input shaft to approximately

100 °C (212 °F) for approximately 10 minutes using a Hot Air

Blower , for example, -VAG1416- .