Volkswagen Golf / Golf GTI / Golf Variant. Service manual - part 493

2.2.3

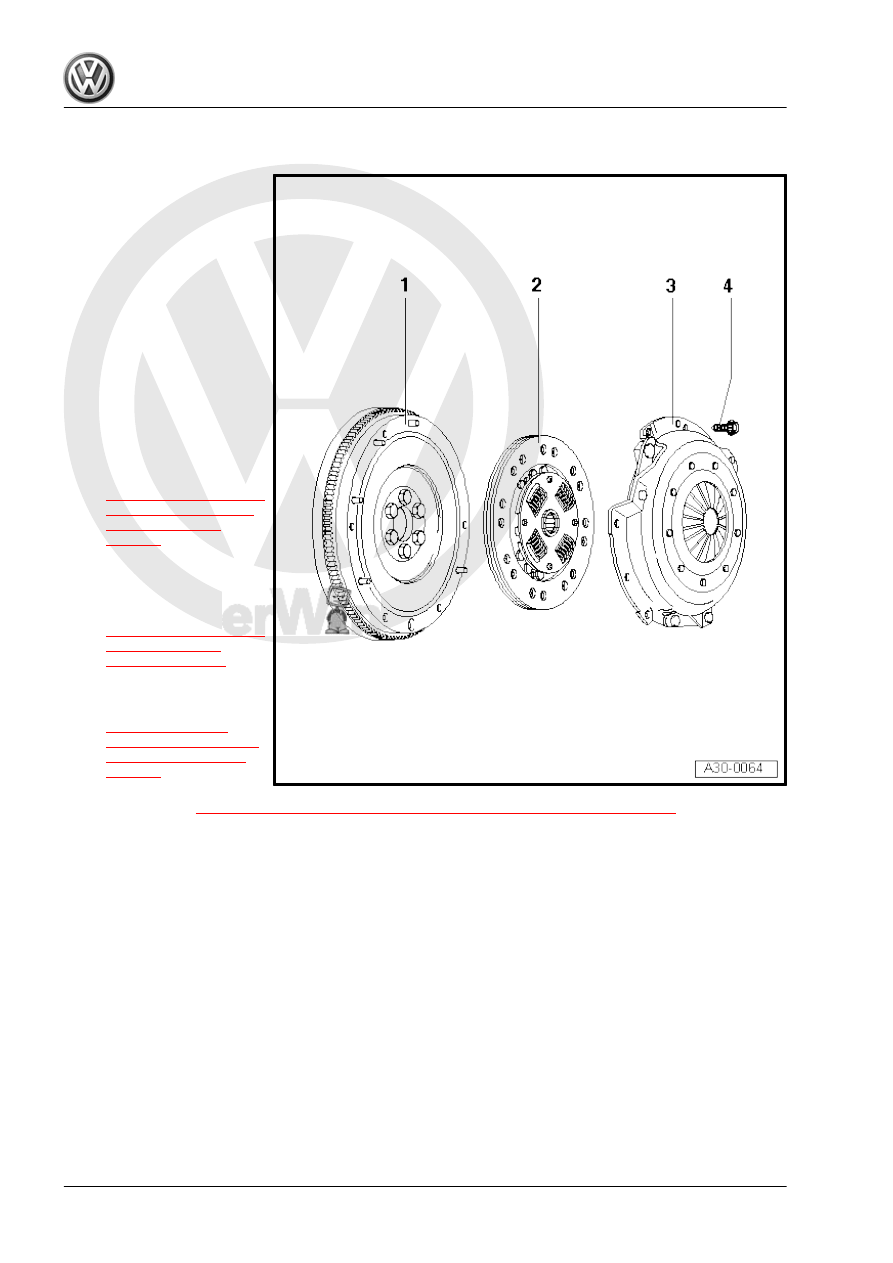

Overview - Clutch, with Single Flywheel

1 - Flywheel

❑ Make sure it fits secure‐

ly on the centering pins

❑ Keep the clutch lining

contact surface free of

grooves, oil and grease

❑ Removing and instal‐

ling. Refer to ⇒ Engine

Mechanical, Fuel Injec‐

tion and Ignition; Rep.

Gr. 13 ; Cylinder Block,

Transmission Side; Fly‐

wheel, Removing and

Installing .

2 - Clutch Plate

❑ Allocation. Refer to the

Parts Catalog.

❑ Centering. Refer to

3 - Pressure Plate

❑ Check the ends of the

diaphragm spring. Refer

to

❑ Checking the spring

connections and rivet

connections. Refer to

❑ Removing and instal‐

ling. Refer to

⇒ “2.3.3 Clutch, Removing and Installing, with Single Flywheel”, page 52

4 - Bolt

❑ M6: 13 Nm

❑ M7: 20 Nm

❑ Loosen and tighten in small steps and in diagonal sequence.

❑ Allocation. Refer to the Parts Catalog.