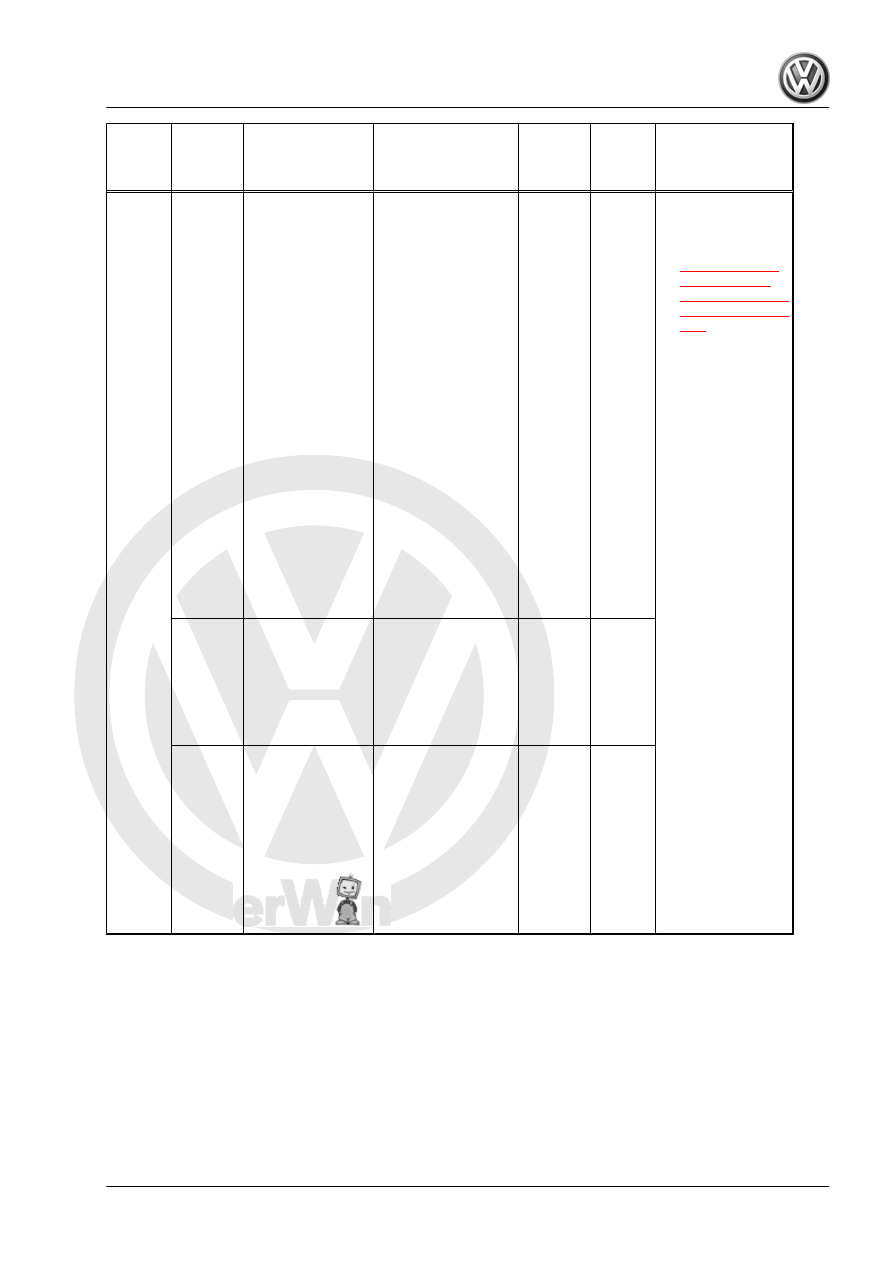

Volkswagen Golf / Golf GTI / Golf Variant. Service manual - part 151

DTC /

Descrip‐

tion

Monitor

Strategy

Descrip‐

tion

Malfunction Crite‐

ria and Threshold

Value

Secondary Parame‐

ters with Enable

Conditions

Monitor‐

ing Time

Length

MIL Il‐

lum.

Component Diag‐

nostic Procedure

P0366

Cam‐

shaft

Position

Sensor

"B" Cir‐

cuit

Range/

Per‐

for‐

mance

Bank 1

Camshaft

Position

(CMP)

Exhaust

Sensor

rationality

check

• Ratio between

measured seg‐

ment time ratio

and specified

camshaft angle

ratio > 2.75 [-]

• Or

• Ratio between

measured seg‐

ment time ratio

and specified

camshaft angle

ratio < 0.36 [-]

• Or

• Offset between

camshaft and

crankshaft <

-24.00° CRK

• Or

• Offset between

camshaft and

crankshaft >

49.00° CRK

• Engine speed

400 – 8,160 rpm

• 990.00°

CRK

• Contin‐

uous

• 2

DCY

– Check the Cam‐

shaft Position

Sensor 3 -

G300- . Refer to

Camshaft

Position

(CMP)

Exhaust

Sensor

signal ac‐

tivity

check

• Segment time

value < 50 [µs]

• Engine speed

400 – 8,160 rpm

• 1440.00°

CRK

• Continu‐

ous

• 2

DCY

Camshaft

Position /

Crank‐

shaft Po‐

sition

(CMP/

CKP) Ex‐

haust

Sensor

out of

range

• Offset between

camshaft and

crankshaft <

-24.00° CRK

• Or

• Offset between

camshaft and

crankshaft >

49.00° CRK

• Engine synchro‐

nization via

crankshaft and

camshaft not fin‐

ished

• Or

• Engine synchro‐

nization via

crankshaft and

camshaft lost

• 450.00°

CRK

• Once /

DCY"

• 2

DCY

GTI 2014 ➤

Generic Scan Tool - Edition 04.2015

3. Diagnosis and Testing

277