Toyota Corolla (2004+). Manual - part 101

16-3

COOLING

- COOLING SYSTEM (April, 2003)

160C5-04

INSPECTION

1.

THERMOSTAT

HINT:

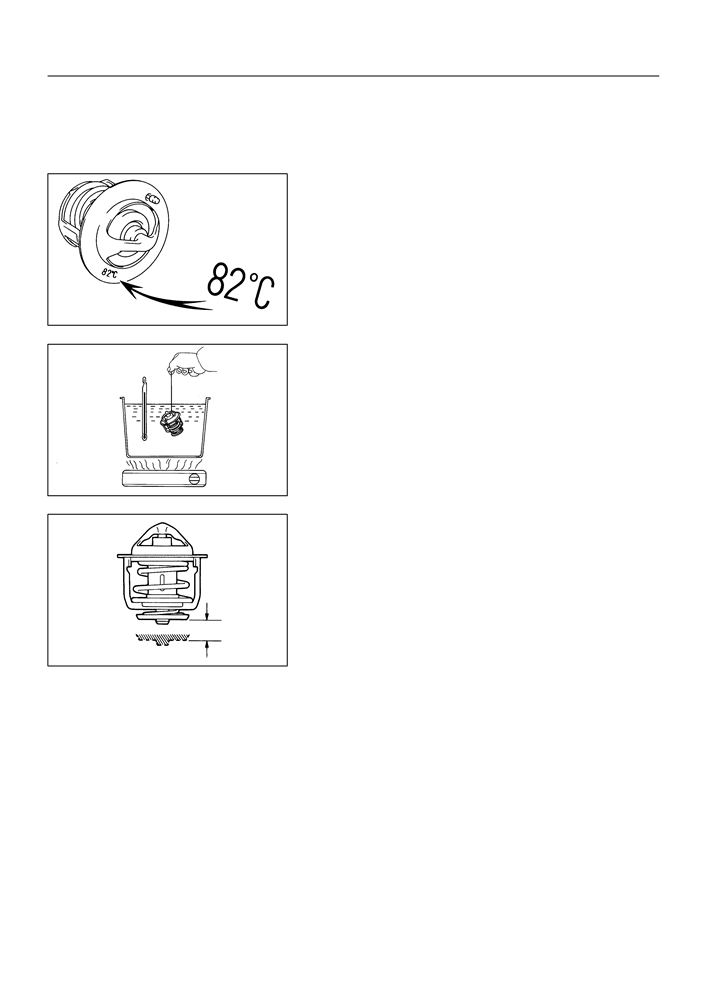

The thermostat is numbered with the valve opening tempera-

ture.

P13560

(a) Immerse the thermostat in water and gradually heat the

water.

(b) Check the valve opening temperature.

Valve opening temperature:

80 to 84 _C (176 to 183 _F)

HINT:

If the valve opening temperature is not as specified, replace the

thermostat.

P00436

(c)

Check the valve lift.

Valve lift: 10 mm (0.39 in.) or more at 95

_C (203_F)

HINT:

If the valve lift is not as specified, replace the thermostat.

(d) Check that the valve is fully closed when the thermostat

is at low temperatures (below 77_C (171_F)).

HINT:

If not closed, replace the thermostat.

P24125

2.

RADIATOR CAP SUB-ASSY

NOTICE:

F

If the radiator cap has contaminations, always rinse

it with water.

F

Before using a radiator cap tester, wet the relief valve

and pressure valve with engine coolant or water.

F

When performing step (a) and (b) below, keep the tes-

ter at an angle of over 30

_ above the horizontal.

16-4

COOLING

- COOLING SYSTEM (April, 2003)

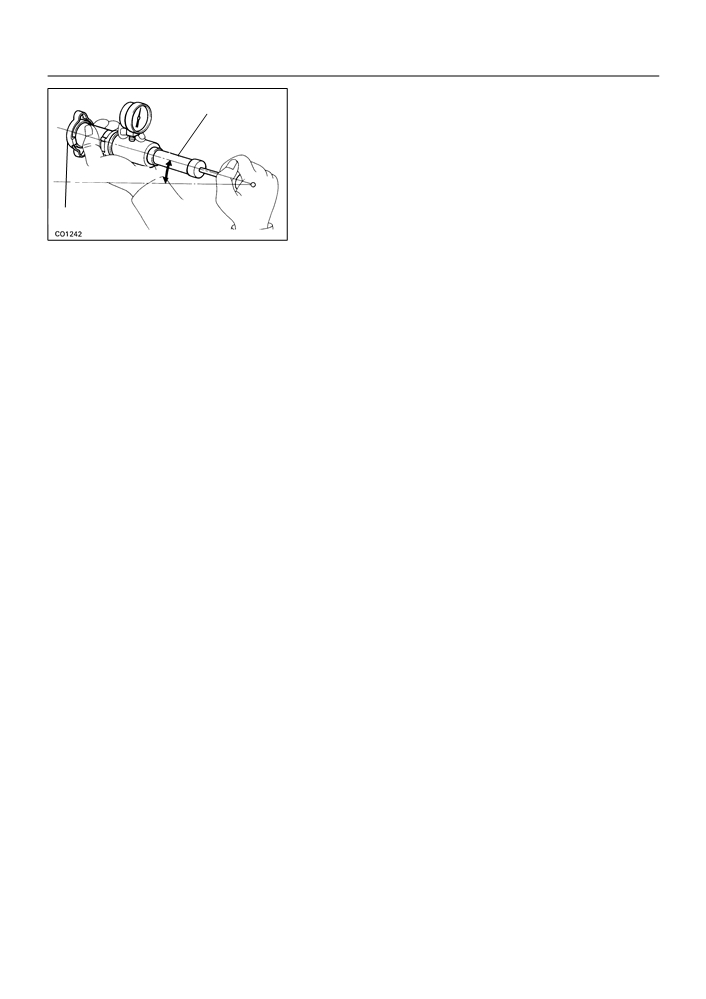

(a) Using a radiator cap tester, slowly pump the tester and

Radiator Cap Tester

check that air is coming from the vacuum valve.

Pump speed: 1 push / 3 seconds or more

NOTICE:

Push the pump at a constant speed.

30_ or more

If air is not coming from the vacuum valve, replace the radiator

cap.

Radiator Cap

(b) Pump the tester and measure the relief valve opening

Z00570

pressure.

Pump speed: 1 push within 1 second

NOTICE:

The above pump speed is for the first pump only (in order

to close the vacuum valve). After the first pump, the pump

speed can be reduced.

Standard opening pressure:

74 to 103 kPa (0.75 to 1.05 kgf/cm 2, 10.7 to 14.9 psi)

Minimum opening pressure:

59 kPa (0.6 kgf/cm 2, 8.5 psi)

HINT:

Use the tester’s maximum reading as the opening pressure.

If the opening pressure is less than minimum, replace the radia-

tor cap.

16-1

COOLING

- COOLING SYSTEM (April, 2003)

COOLING SYSTEM (April, 2003)

160NX-02

ON-VEHICLE INSPECTION

1.

INSPECT COOLING SYSTEM FOR LEAKS

Radiator Cap Tester

CAUTION:

To avoid the danger of being burned, do not remove the ra-

diator cap while the engine and radiator are still hot, as fluid

and steam can be blown out under pressure.

(a) Fill the radiator with coolant and attach a radiator cap tes-

ter.

(b) Warm up the engine.

A65935

(c)

Pump it to 118 kPa (1.2 kgf/cm2, 17.1 psi), and check that

the pressure does not drop.

HINT:

If the pressure drops, check the hoses, radiator or water pump

for leaks. If no external leaks are found, check the heater core,

cylinder block and head.

2.

CHECK ENGINE COOLANT LEVEL AT RESERVOIR

(a) The engine coolant level should be between the ”LOW” and ”FULL” line.

HINT:

If low, check for leaks and add ”Toyota Long Life Coolant” or equivalent up to the ”FULL” line.

3.

CHECK ENGINE COOLANT QUALITY

(a) Remove the radiator cap.

CAUTION:

To avoid the danger of being burned, do not remove the radiator cap while the engine and radiator

are still hot, as fluid and steam can be blown out under pressure.

(b) Check if there is any excessive deposits of rust or scale around the radiator cap and radiator filler hole;

the coolant should be free from oil.

HINT:

If excessively dirty, replace the coolant.

(c)

Reinstall the radiator cap.

16-2

COOLING

- COOLING SYSTEM (April, 2003)

4.

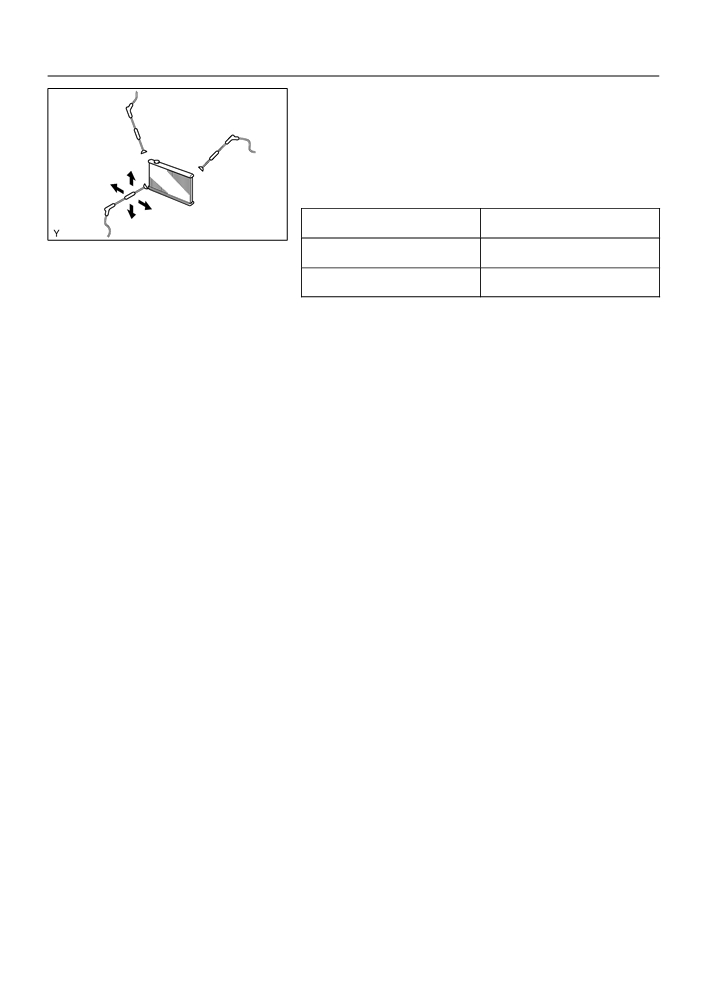

INSPECT FINS BLOCKAGE

(a) If fins are clogged, wash them with water or a steam

cleaner and dry with compressed air.

NOTICE:

F

If the distance between the steam cleaner and core is

too close, there is a possibility of damaging the fins,

so keep the following injection distance.

Injection Pressures

Injection Distance

kPa (kgf/cm2, psi)

mm (in.)

A73603

2,942 to 4,903

300 (11.811)

(30 to 50, 427 to 711)

4,903 to 7,845

500 (19.685)

(50 to 80, 711 to 1,138)

F

If the fins are bent, straighten them with a screwdriver

or pliers.

F

Be careful not pour water directly onto electronic

components.

16-13

COOLING

- RADIATOR ASSY

RADIATOR ASSY

160CC-02

REPLACEMENT

1.

DRAIN COOLANT(See page 16-7)

2.

SEPARATE RADIATOR HOSE INLET

3.

SEPARATE RADIATOR HOSE OUTLET

4.

SEPARATE OIL COOLER INLET TUBE NO.1

5.

SEPARATE OIL COOLER OUTLET TUBE NO.1

6.

REMOVE RADIATOR ASSY

(a) Disconnect the fan motor connector.

(b) Disconnect two clamps for wire-harness from fan-shroud.

(c)

Remove the two fan mount bolts.

(d) Remove the fan w/motor.

7.

ADD COOLANT (See page 16-7)

8.

CHECK ENGINE COOLANT LEAK (See page 16-7)

16-11

COOLING

- THERMOSTAT

THERMOSTAT

160CB-01

REPLACEMENT

1.

REMOVE ENGINE UNDER COVER RH

2.

DRAIN COOLANT (See page 16-7)

3.

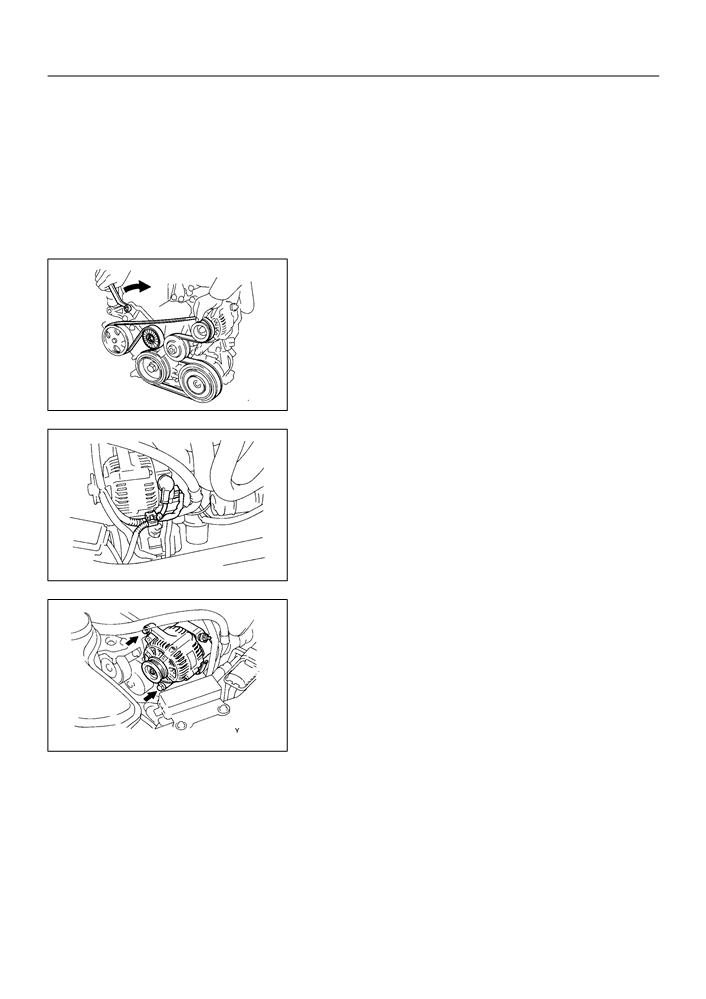

REMOVE FAN AND GENERATOR V BELT

(See page 14-4)

B00145

4.

REMOVE GENERATOR ASSY

(a) Disconnect the wire clamp from the wire clip on the recti-

fire end frame.

(b) Remove the rubber cap and nut, and disconnect the alter-

nator wire.

(c)

Disconnect the alternator connector.

B00143

(d) Remove the 2 bolts and alternator.

B00147

5.

REMOVE WATER INLET

6.

REMOVE THERMOSTAT

16-12

COOLING

- THERMOSTAT

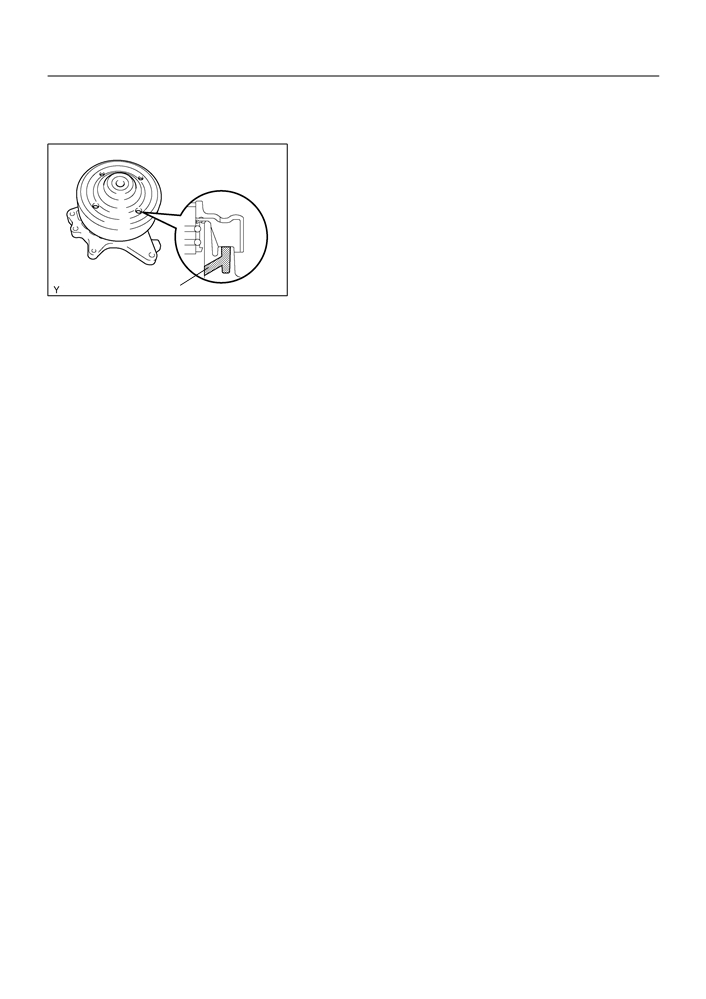

7.

INSTALL THERMOSTAT

(a) Install a new gasket to the thermostat.

10F

10F

(b) Install the thermostat with the jiggle valve upward as

shown in the illustration.

A62118

8.

INSTALL WATER INLET

Torque: 11 N m (113 kgf cm, 8 ft lbf)

9.

INSTALL GENERATOR ASSY

Torque:

12mm head 25 N m (250 kgf cm, 18 ft lbf)

14mm head 54 N m (550 kgf cm, 39 in. lbf)

10. ADD COOLANT (See page 16-7)

11. CHECK ENGINE COOLANT LEAK (See page 16-7)

16-10

COOLING

- WATER PUMP ASSY

160CA-01

INSPECTION

1.

INSPECT WATER PUMP ASSY

(a) Visually check the drain hole for coolant leakage.

Hole

B10233

16-8

COOLING

- WATER PUMP ASSY

WATER PUMP ASSY

160C9-01

REPLACEMENT

1.

REMOVE ENGINE UNDER COVER RH

2.

DRAIN COOLANT (See page 16-7)

3.

REMOVE FAN AND GENERATOR V BELT

(See page 14-4)

B00145

4.

REMOVE GENERATOR ASSY

(a) Disconnect the wire clamp from the wire clip on the recti-

fire end frame.

(b) Remove the rubber cap and nut, and disconnect the alter-

nator wire.

(c)

Disconnect the alternator connector.

B00143

(d) Remove the 2 bolts and alternator.

B00147

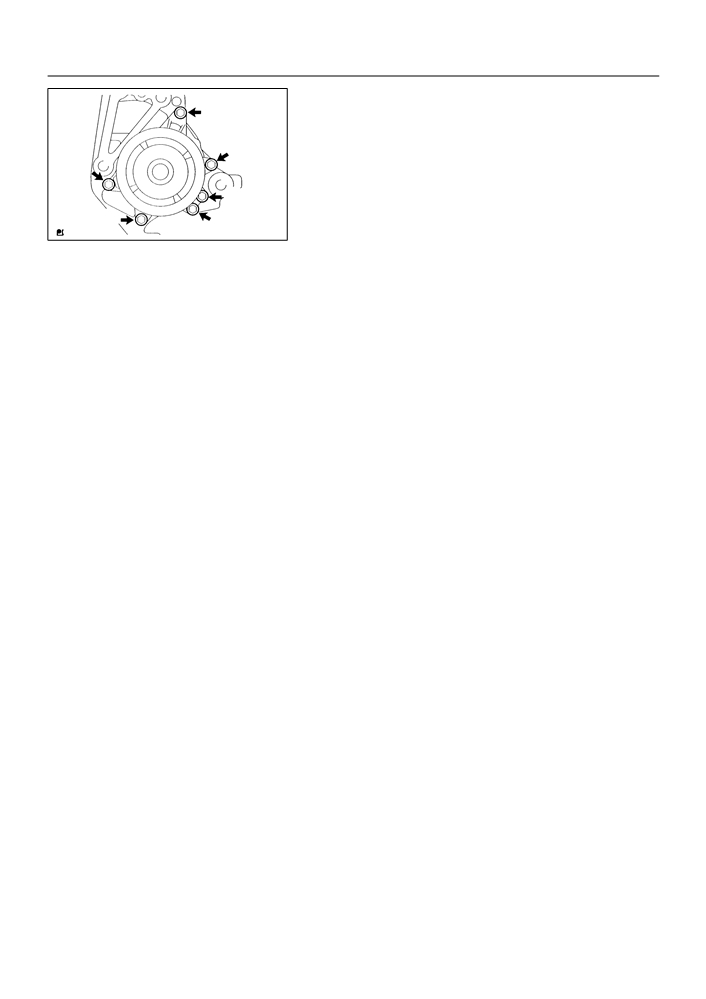

5.

REMOVE WATER PUMP ASSY

(a) Remove the 6 bolts, water pump and O-ring.

B00150

16-9

COOLING

- WATER PUMP ASSY

6.

INSTALL WATER PUMP ASSY

B

(a) Place a new O-ring on the timing chain cover.

(b) Install the water pump with the 6 bolts.

Torque:

B

Bolt A 9.0 N m (92 kgf cm, 80 in lbf)

A

Bolt B 11 N m (113 kgf cm, 8 ft lbf)

B

B

A

A32555

7.

INSTALL GENERATOR ASSY

Torque:

12 mm head 25 N m (250 kgf cm, 18 ft lbf)

14 mm head 54 Nm (550 kgf cm, 39 ft lbf)

8.

ADD COOLANT (See page 16-7)

9.

CHECK ENGINE COOLANT LEAK (See page 16-7)

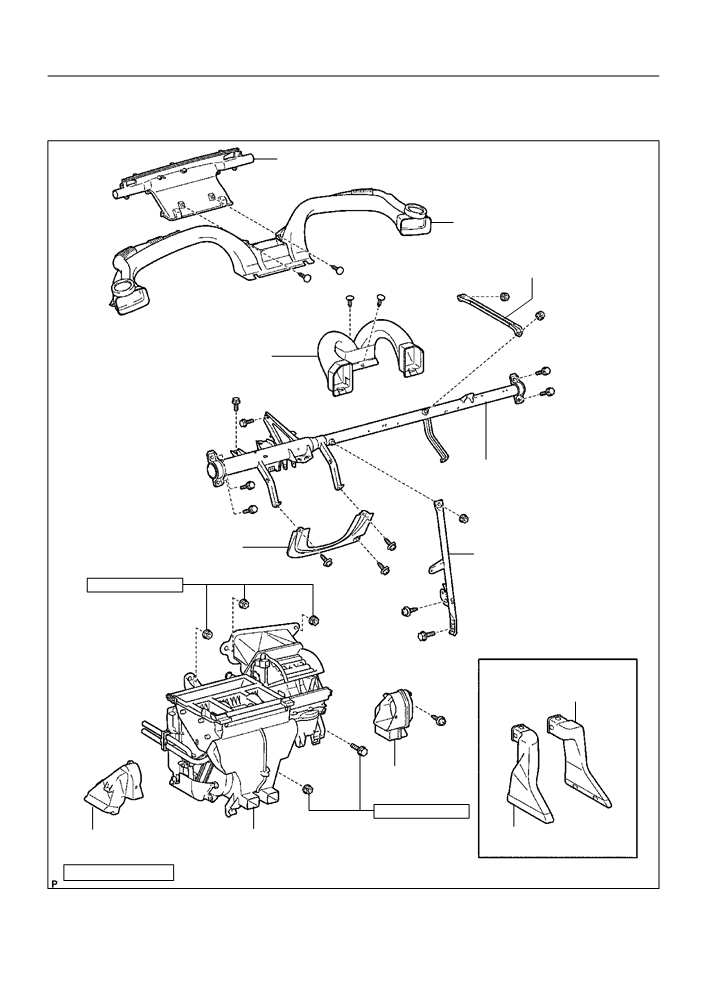

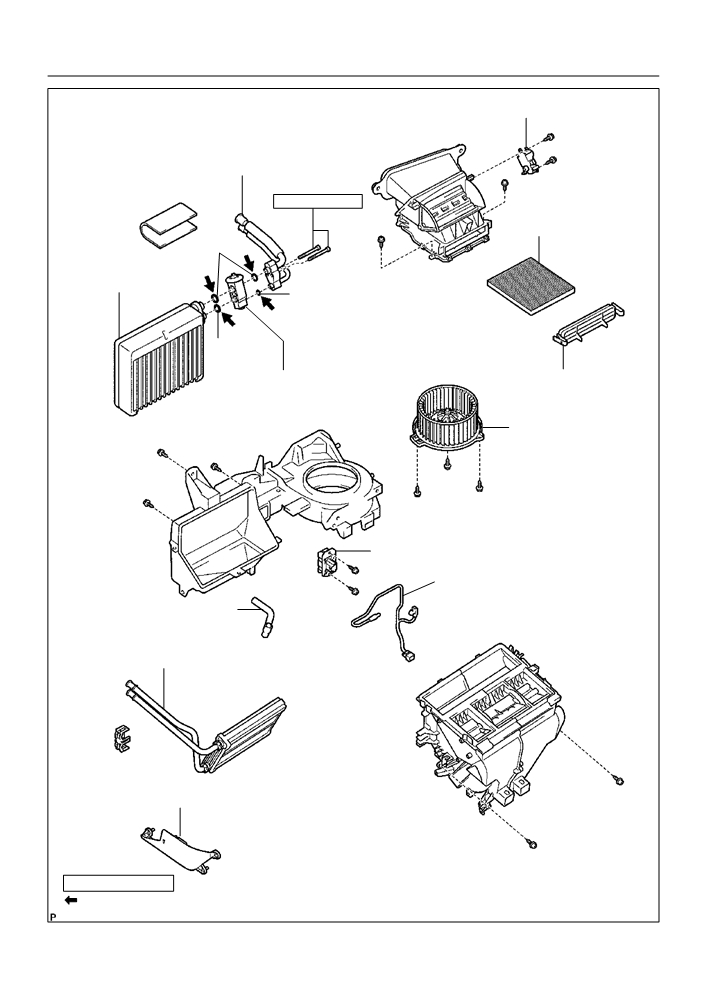

55-15

HEATER & AIR CONDITIONER

- AIR CONDITIONING UNIT ASSY

AIR CONDITIONER UNIT ASSY

550IU-01

COMPONENTS

Defroster Nozzle Assy

Heater to Register Duct No.1

Instrument Panel to Cowl

Brace Center

Heater to Register

Duct No.2

Instrument Panel Reinforcement

Instrument Panel LWR

Instrument Panel Brace

Insert LH

Sub-assy No.1

9.8 (100, 87 in. lbf)

w/ Cold Area:

Air Duct Rear No.4

Air Duct No.2

9.8 (100, 87 in. lbf)

Air Duct No.1

Air Conditioner Unit Assy

Air Duct Rear No.3

Nm (kgfcm, ftlbf)

: Specified torque

I32531

55-16

HEATER & AIR CONDITIONER

- AIR CONDITIONING UNIT ASSY

Damper Servo Sub-assy

Air Conditioning Tube Assy

3.5 (35, 30 in. lbf)

Air Filter

_ O-Ring

Cooler Evaporator

Sub-assy No.1

_ O-Ring

_ O-Ring

Cooler Expansion Valve

Air Filter Case

Blower w/ fan Motor

Sub-assy

Blower Resistor

Cooler Thermistor No.1

Cooler Unit Drain Hose No.1

Heater Radiator Unit Sub-assy

Heater Piping Cover

Nm (kgfcm, ftlbf)

: Specified torque

Compressor Oil ND-OIL 8 or equivalent

_ Non-reusable Part

I32532

55-17

HEATER & AIR CONDITIONER

- AIR CONDITIONING UNIT ASSY

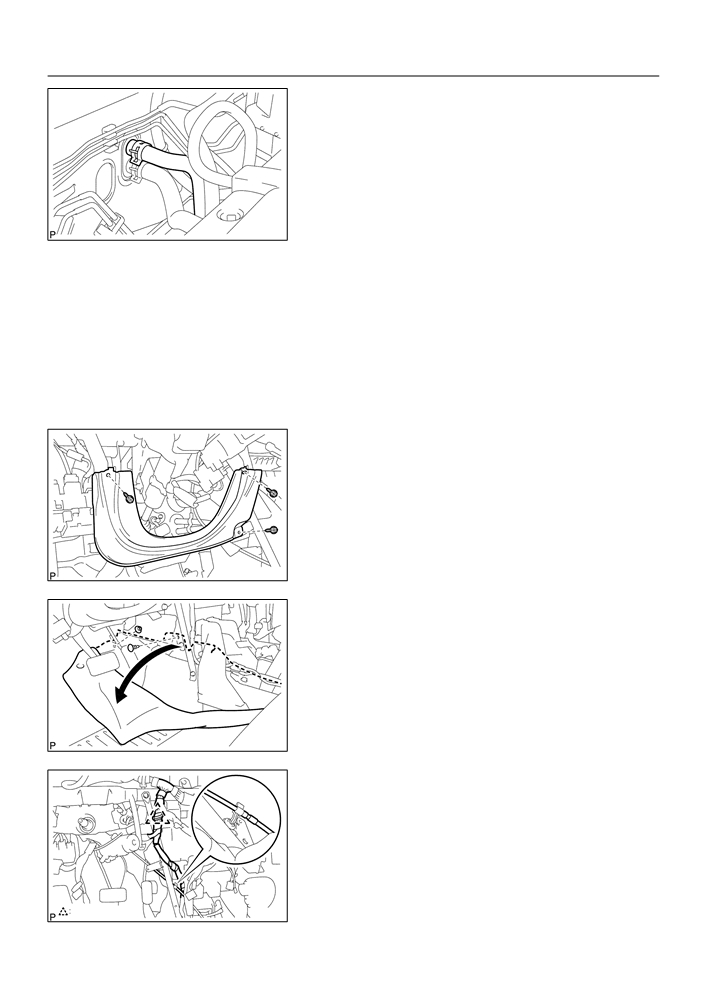

550IV-02

OVERHAUL

HINT:

COMPONENT: See page 55-15

1.

DISCHARGE REFRIGERANT FROM REFRIGERATION SYSTEM (See page 55-11)

SST

07110-58060 (07117-58080, 07117-58090, 07117-78050, 07117-88060, 07117-88070,

07117-88080)

2.

DISCONNECT COOLER REFRIGERANT SUCTION

HOSE NO.1

(a) Install SST to piping clamp.

SST

09870-00015

HINT:

SST

Confirm the direction of the piping clamp claw and SST using

the illustration showing on the caution label.

I03838

(b) Push down SST and release the clamp lock.

Push

Pull

NOTICE:

Be careful not to deform the tube, when pushing SST.

(c)

Pull SST slightly and push the release lever, then remove

the piping clamp with SST.

(d) Remove the piping clamp from SST.

SST

Release

Lever

I03839

(e) Disconnect the cooler refrigerant suction hose No. 1.

Disconnect the

NOTICE:

tube using hand

Screw

F

Do not use tools like screwdriver to remove the tube.

Driver

F

Cap the open fittings immediately to keep moisture or

dirt out of the system.

I06919

3.

DISCONNECT COOLER REFRIGERANT LIQUID PIPE A

SST

09870-00015

HINT:

Disconnect in the same way as the cooler refrigerant suction hose No. 1.

55-18

HEATER & AIR CONDITIONER

- AIR CONDITIONING UNIT ASSY

4.

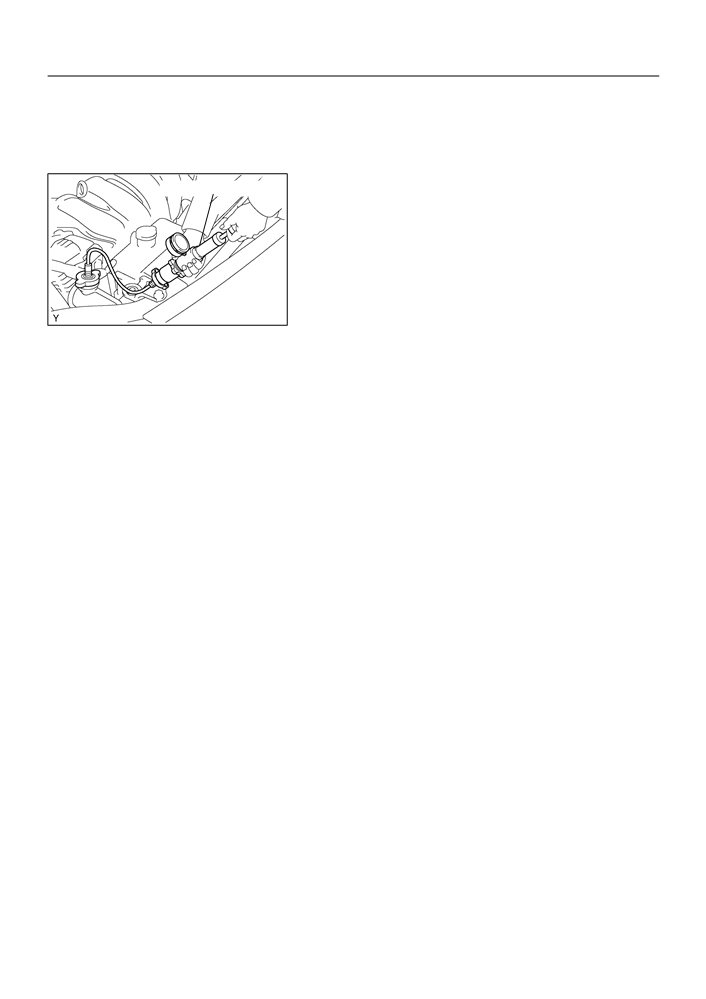

DISCONNECT HEATER INLET WATER HOSE

(a) Using pliers, grip the claws of clip and slide the clip and

disconnect the heater inlet water hose.

I32426

5.

DISCONNECT HEATER OUTLET WATER HOSE

HINT:

Disconnect in the same way as the heater inlet water hose.

6.

REMOVE INSTRUMENT PANEL SUB-ASSY LOWER (See page 71-10)

HINT:

Refer to the manuals for removal of the instrument panel sub-assy lower.

7.

REMOVE INSTRUMENT PANEL LWR PAD INSERT LH

(a) Remove the 3 screws and instrument panel LWR pad in-

sert LH.

I32436

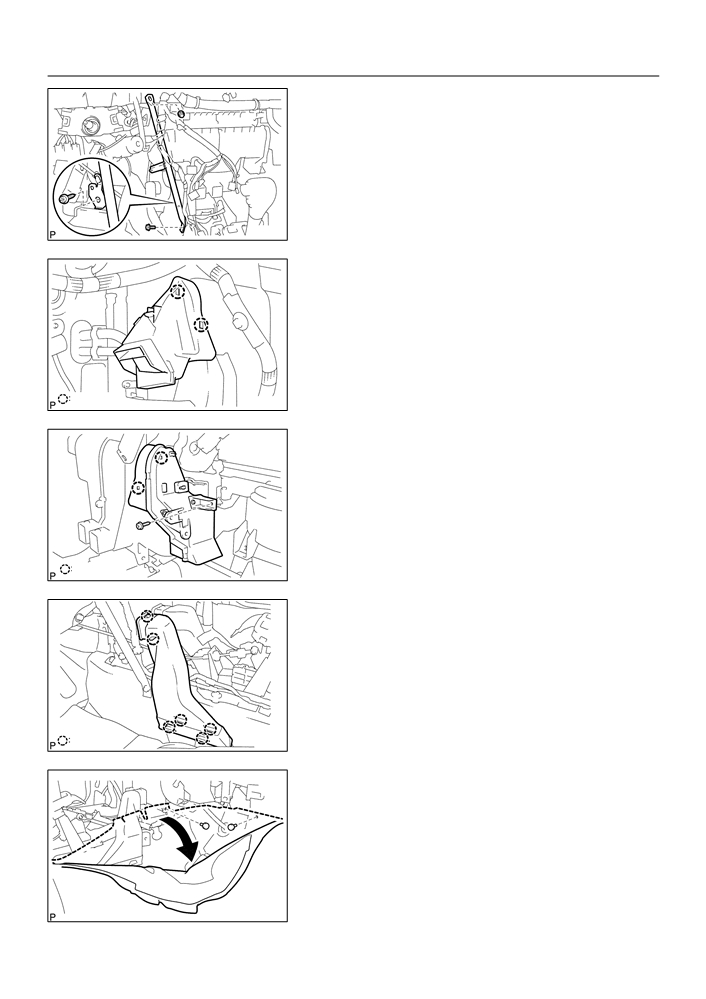

8.

REMOVE INSTRUMENT PANEL BRACE SUB-ASSY

NO.1

(a) Remove 2 clips and take up the floor carpet.

HINT:

Take up the floor carpet as small as the instrument panel brace

sub-assy No. 1 can be removed.

I32432

(b) Remove the clamp and floor shift parking lock cable assy.

Clamp

I32437

55-19

HEATER & AIR CONDITIONER

- AIR CONDITIONING UNIT ASSY

(c)

Remove the screw.

(d) Remove the bolt, nut and instrument panel brace sub-

assy No. 1.

I32438

9.

REMOVE AIR DUCT NO.1

(a) Release the 2 fitting claws, remove the air duct No. 1.

2 Claws

I32439

10. REMOVE AIR DUCT NO.2

(a) Remove the screw.

(b) Release the 2 fitting claws, remove the air duct No. 2.

2 Claws

I32440

11. REMOVE AIR DUCT REAR NO.3 (W/ COLD AREA)

(a) Release the 6 fitting claws, remove the air duct rear No.3.

6 Claws

I32433

12. REMOVE AIR DUCT REAR NO.4 (W/ COLD AREA)

(a) Remove 2 clips and take up the floor carpet.

HINT:

Take up the floor carpet as small as the air duct rear No.4 can

be removed.

I32434