Toyota Corolla (2004+). Manual - part 14

19-6

STARTING & CHARGING

- STARTER ASSY (1ZZ-FE) (April, 2003)

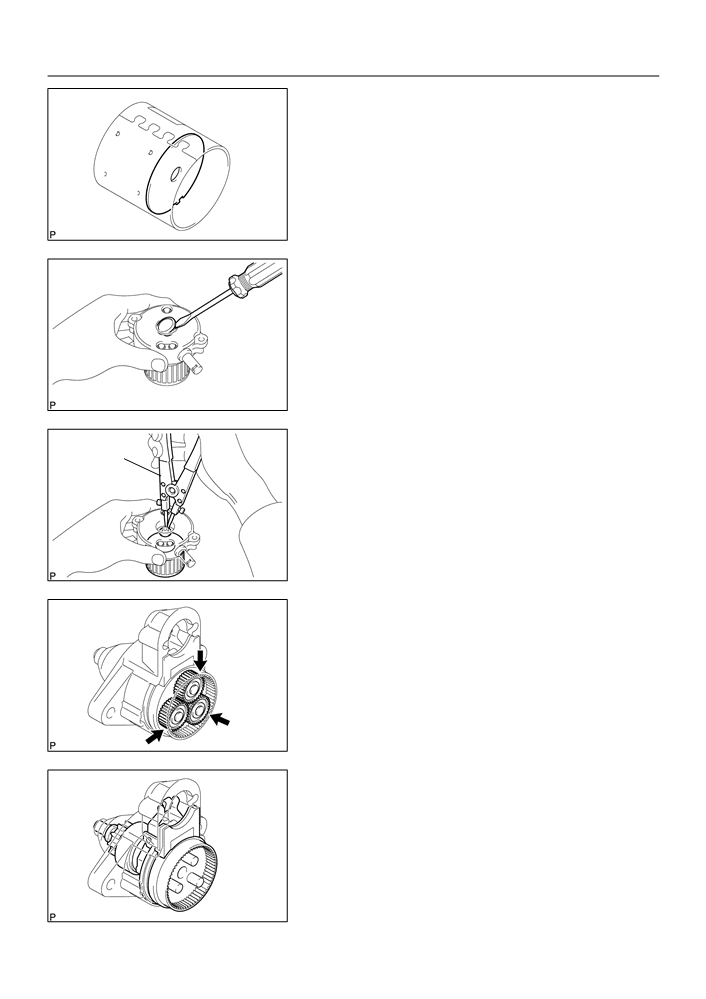

3.

REMOVE STARTER ARMATURE PLATE

(a) Remove the starter armature plate from the starter yoke.

A83803

4.

REMOVE STARTER COMMUTATOR END FRAME

COVER

(a) Using a screwdriver, remove the starter commutator end

frame cover.

A83801

5.

REMOVE STARTER ARMATURE ASSY

Snap Ring

(a) Using snap ring pliers, remove the snap ring.

Pliers

(b) Remove the washer and starter armature from the starter

commutator end frame.

A83802

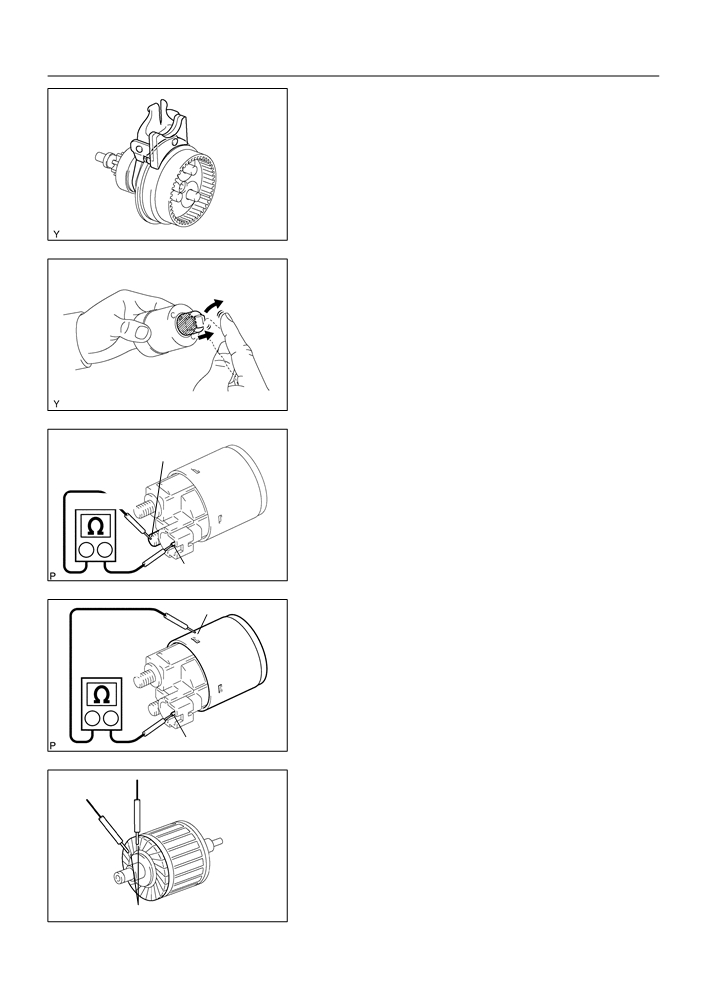

6.

REMOVE PLANETARY GEAR

(a) Remove the 3 planetary gears from the starter center

bearing clutch.

A83804

7.

REMOVE STARTER CENTER BEARING CLUTCH

SUB-ASSY

(a) Remove the starter center bearing clutch together with

the starter drive lever set pin from the starter drive hous-

ing.

A83805

19-7

STARTING & CHARGING

- STARTER ASSY (1ZZ-FE) (April, 2003)

8.

REMOVE STARTER DRIVE LEVER SET PIN

(a) Remove the starter drive lever set pin from the starter cen-

ter bearing clutch.

A73990

9.

INSPECT REPAIR SERVICE STARTER KIT

(a) Check the operation.

(1)

Push in the plunger, then check that it returns quick-

ly to its original position.

If necessary, replace the repair service starter kit.

A58586

(b) Check the continuity.

Terminal C

(1)

Using an ohmmeter, check that there is continuity

between terminals 50 and C.

Continuity

If there is no continuity, replace the repair service starter kit.

Ohmmeter

Terminal 50

A84614

Switch Body

(2)

Using an ohmmeter, check that there is continuity

Continuity

between terminal 50 and the switch body.

If there is no continuity, replace the repair service starter kit.

Ohmmeter

Terminal 50

A84615

10. INSPECT STARTER ARMATURE ASSY

Continuity

(a) Check the continuity.

(1)

Using an ohmmeter, check that there is continuity

between the segments of the commutator.

If there is no continuity between any segments, replace the

starter armature.

Segment

A79764

19-8

STARTING & CHARGING

- STARTER ASSY (1ZZ-FE) (April, 2003)

(2)

Using an ohmmeter, check that there is no continu-

No Continuity

ity between the commutator and armature coil core.

If there is continuity, replace the starter armature.

(b) Check the commutator surface for dirt or burn.

If the surface is dirty or burnt, smooth the surface with 400-grit

sandpaper or lathe.

Commutator

Coil Core

A79765

(c)

Check the commutator depth.

(1)

Using vernier calipers, measure the commutator

depth.

Standard depth: 3.1 mm (0.122 in.)

Depth

Maximum depth: 3.8 mm (0.150 in.)

If the depth is greater than maximum, replace the starter arma-

ture.

A58584

11. INSPECT STARTER COMMUTATOR END FRAME

ASSY

(a) Check the brush length.

(1)

Using vernier calipers, measure the brush length.

Length

Standard length: 9.0 mm (0.354 in.)

Minimum length: 4.0 mm (0.158 in.)

If the length is less than minimum, replace the starter commuta-

tor end frame.

A76677

(b) Check the continuity.

No Continuity

(1)

Using an ohmmeter, check that there is no continu-

ity between the positive (+) and negative (-) brush.

If there is continuity, repair or replace the starter commutator

end frame.

A79766

12. INSPECT STARTER CENTER BEARING CLUTCH

SUB-ASSY

Free

(a) Check the starter clutch.

(1)

Rotate the clutch pinion gear clockwise, then check

that it turns freely. Try to rotate the clutch pinion gear

counterclockwise, then check that it locks.

If necessary, replace the starter center bearing clutch.

Lock

A83810

19-9

STARTING & CHARGING

- STARTER ASSY (1ZZ-FE) (April, 2003)

(b) Check the wear or damage.

(1)

Inspect the gear teeth on the planetary gear, inter-

nal gear and starter clutch for wear or damage.

If damaged, replace the starter center bearing clutch.

13. INSTALL STARTER DRIVE LEVER SET PIN

(a) Install the starter drive lever set pin to the starter center

bearing clutch as shown in the illustration.

A84665

14. INSTALL STARTER CENTER BEARING CLUTCH

SUB-ASSY

(a) Install the starter center bearing clutch together with the

starter drive lever set pin to the starter drive housing.

A83805

15. INSTALL PLANETARY GEAR

(a) Apply grease to the planetary gears and pin parts of the

planetary shaft.

(b) Install the 3 planetary gears to the starter center bearing

clutch.

A83804

19-10

STARTING & CHARGING

- STARTER ASSY (1ZZ-FE) (April, 2003)

16. INSTALL STARTER ARMATURE ASSY

Snap Ring

(a) Apply grease to the washer and the armature shaft.

Pliers

(b) Install the starter armature and the washer to the starter

commutator end frame.

(c)

Using snap ring pliers, install a new snap ring.

A83802

(d) Check the snap ring length.

(1)

Using vernier calipers, measure the snap ring

Length

length.

Maximum length: 5.0 mm (0.197 in.)

If the length is greater than maximum, replace it with a new snap

ring.

A58810

17. INSTALL STARTER COMMUTATOR END FRAME

COVER

(a) Install the starter commutator end frame cover to the

starter commutator end frame.

A84616

18. INSTALL STARTER ARMATURE PLATE

Key

(a) Align the keyway of the starter armature plate with the key

Keyway

inside the starter yoke, then install the armature plate to

the starter yoke.

A73991

19. INSTALL STARTER COMMUTATOR END FRAME

Rubber

ASSY

Cutout

(a) Align the rubber with the cutout of the starter yoke, then

install the starter commutator end frame to the starter

yoke.

A79727

19-11

STARTING & CHARGING

- STARTER ASSY (1ZZ-FE) (April, 2003)

20. INSTALL STARTER YOKE ASSY

(a) Align the key of the starter yoke with the keyway of the

starter drive housing, then install the starter yoke to the

starter drive housing.

Keyway

Key

A84617

(b) Tighten the 2 through bolts.

Torque: 6.0 N m (61 kgf cm, 53 in. lbf)

A83799

21. INSTALL REPAIR SERVICE STARTER KIT

(a) Apply grease to the plunger and hook.

(b) Hang the plunger hook of the repair service starter kit to

the starter drive lever set pin.

(c)

Install the plunger and return spring.

A84618

(d) Install the repair service starter kit with the 2 screws.

Torque: 7.5 N m (76 kgf cm, 66 in. lbf)

A83798

(e) Connect the lead wire to terminal C with the nut.

Torque: 10 N m (102 kgf cm, 7 ft lbf)

A83797

19-4

STARTING & CHARGING

- STARTER ASSY (1ZZ-FE) (April, 2003)

190QQ-02

REPLACEMENT

1.

DISCONNECT BATTERY NEGATIVE TERMINAL

2.

REMOVE ENGINE UNDER COVER RH

3.

REMOVE STARTER ASSY

Terminal Cover

(a) Disconnect the starter connector.

(d)

(b) Open the terminal cover.

(c)

Remove the nut, then disconnect the starter wire.

(c)

(d) Remove the 2 bolts, then remove the starter.

(d)

(a)

A51076

4.

INSTALL STARTER ASSY

Torque:

37 Nm (378 kgf cm, 27 ft lbf) for bolt

9.8 Nm (100 kgf cm, 7 ft lbf) for nut

5.

INSTALL ENGINE UNDER COVER RH

6.

CONNECT BATTERY NEGATIVE TERMINAL

Torque: 5.4 N m (55 kgf cm, 48 in. lbf)

26-17

FRONT SUSPENSION

- LOWER BALL JOINT ASSY FRONT LH

LOWER BALL JOINT ASSY FRONT LH

2607Y-04

REPLACEMENT

HINT:

COMPONENTS: See page 26-3

1.

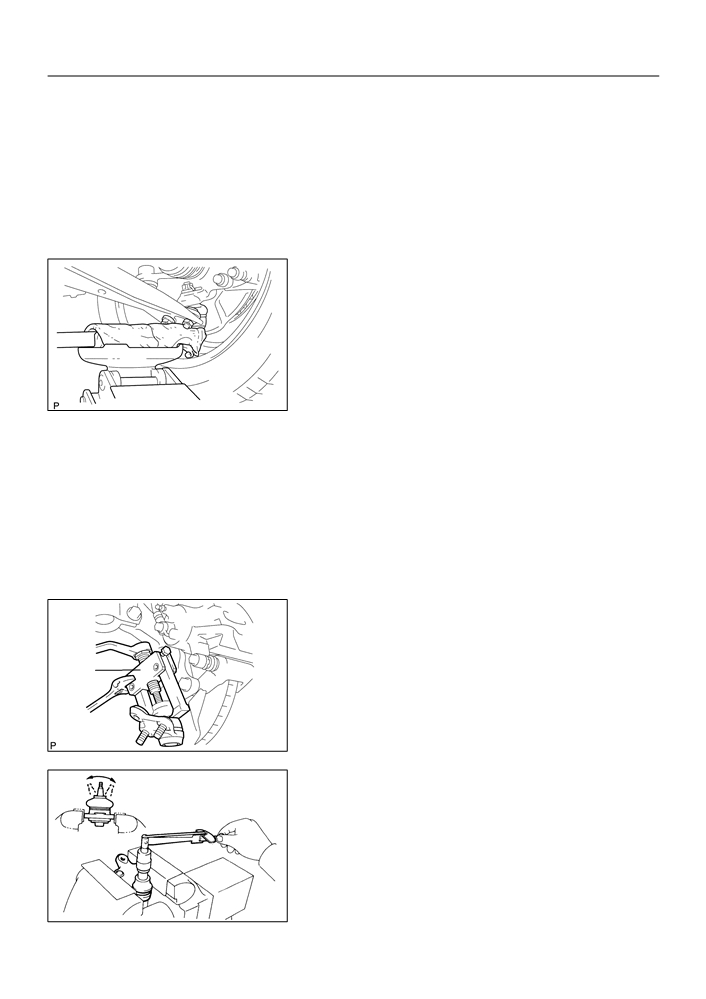

INSPECT LOWER BALL JOINT ASSY FRONT LH

(a) Jack up front side of the vehicle.

(b) Check the rattle of the lower ball joint assy front LH.

C54719

2.

REMOVE FRONT WHEEL

3.

REMOVE FRONT AXLE HUB LH NUT(See page 30-6)

SST

09930-00010

4.

DISCONNECT SPEED SENSOR FRONT LH (W/ ABS)(See page 30-6)

5.

SEPARATE TIE ROD END SUB-ASSY LH(See page 30-6)

SST

09628-62011

6.

SEPARATE FRONT SUSPENSION ARM SUB-ASSY LOWER NO.1 LH(See page 30-6)

7.

SEPARATE FRONT AXLE ASSY LH(See page 30-6)

8.

REMOVE LOWER BALL JOINT ASSY FRONT LH

(a) Remove the cotter pin and castle nut.

(b) Using SST, remove the lower ball joint assy from the

steering knuckle LH.

SST

SST

09628-62011

C95204

9.

INSPECT LOWER BALL JOINT ASSY FRONT LH

(a) As shown in the illustration, flip the ball joint stud back and

forth 5 times, before installing the nut.

(b) Using a torque wrench, turn the nut continuously at a rate

of 3 - 5 seconds per 1 turn and take the torque reading

on the 5th turn.

Turning torque:

0.98 - 4.9 Nm (10 - 50 kgf cm, 8.7 - 43 in. lbf)

ZX1712

26-18

FRONT SUSPENSION

- LOWER BALL JOINT ASSY FRONT LH

10. INSTALL LOWER BALL JOINT ASSY FRONT LH

(a) Install the lower ball joint assy front LH to the steering knuckle LH, tighten the castle nut.

Torque: 103 N m (1050 kgf cm, 76 ft lbf)

(b) Install a new cotter pin.

11. INSTALL FRONT AXLE ASSY LH(See page

30-6)

12. INSTALL FRONT SUSPENSION ARM SUB-ASSY LOWER NO.1 LH(See page

30-6)

13. INSTALL TIE ROD END SUB-ASSY LH(See page

30-6)

14. INSTALL SPEED SENSOR FRONT LH (W/ ABS)(See page 30-6)

15. INSTALL FRONT AXLE HUB LH NUT(See page

30-6)

SST

09931-00020

16. INSTALL FRONT WHEEL

Torque: 103 N m (1,050 kgf cm, 76 ft lbf)

17. INSPECT AND ADJUST FRONT WHEEL ALIGNMENT(See page 26-5)

18. CHECK ABS SPEED SENSOR SIGNAL (W/ ABS)(See page

05-297)

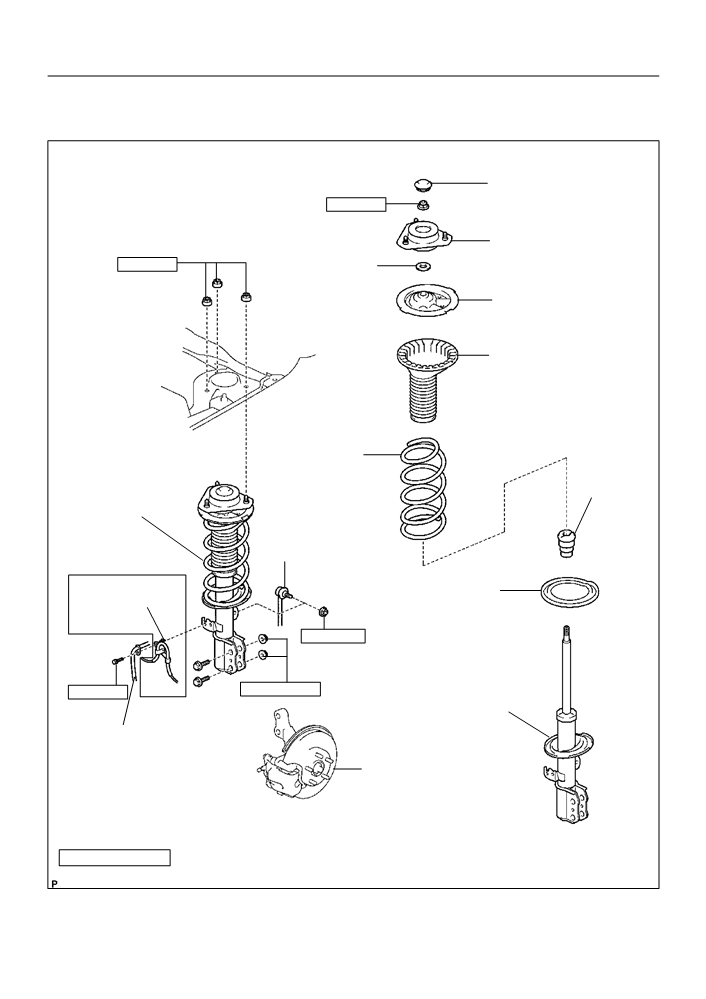

26-3

FRONT SUSPENSION

- FRONT SUSPENSION

FRONT SUSPENSION

2607U-01

COMPONENTS

Front Suspension

Support Dust Cover LH

F

47 (479, 35)

Front Suspension

Support Sub-assy LH

39 (398, 29)

Front Suspension

Support LH

Dust Seal

Front Coil Spring

Seat Upper LH

Front Coil Spring

Insulator Upper LH

Front Coil

Spring LH

Front Spring

Bumper LH

Front Shock

Absorber with

Front Stabilizer

Coil Spring

Link Assy LH

w/ ABS:

Front Coil

Speed Sensor

Spring Insulator

Front LH

Lower LH

74 (755, 55)

153 (1,560, 113)

29 (296, 21)

Shock Absorber

Assy Front LH

Front Flexible Hose

Front Axle Assy

Nm (kgfcm, ftlbf)

: Specified torque

F Non-reusable part

C95203

26-4

FRONT SUSPENSION

- FRONT SUSPENSION

58 (591, 43)

58 (591, 43)

Rack & Pinion Power

Steering Gear Assy

19 (194, 14)

Front Stabilizer Bracket No.1 RH

Front Stabilizer Bar Bush No.1

Stabilizer Bar Front

19 (194, 14)

Front Stabilizer

Link Assy RH

Front Stabilizer

Bracket No.1 LH

74 (755, 55)

Front Stabilizer Bar

Bush No.1

Front Stabilizer

Link Assy LH

157 (1,601, 116)

74 (755, 55)

49 (500, 36)

157 (1,601, 116)

FCotter Pin

74 (755, 55)

Front Suspension

Crossmember

Sub-assy

FCotter Pin

113 (1,152, 83)

137 (1,397, 101)

52 (530, 38)

137 (1,397, 101)

F

216 (2,203, 159)

103 (1,050, 76)

Front Suspension Arm

Sub-assy Lower No.1 LH

Lower Ball Joint Assy

Front LH

113 (1,152, 83)

29 (296, 21)

Front Flexible Hose

89 (908, 66)

29 (296, 21)

Front Drive Shaft

w/ ABS:

Assy LH

Nm (kgfcm, ftlbf)

: Specified torque

Speed Sensor Front LH

F Non-reusable part

C95200

26-5

FRONT SUSPENSION

- FRONT WHEEL ALIGNMENT

FRONT WHEEL ALIGNMENT

2607T-01

ADJUSTMENT

1.

INSPECT TIRE(See page 28-1)

2.

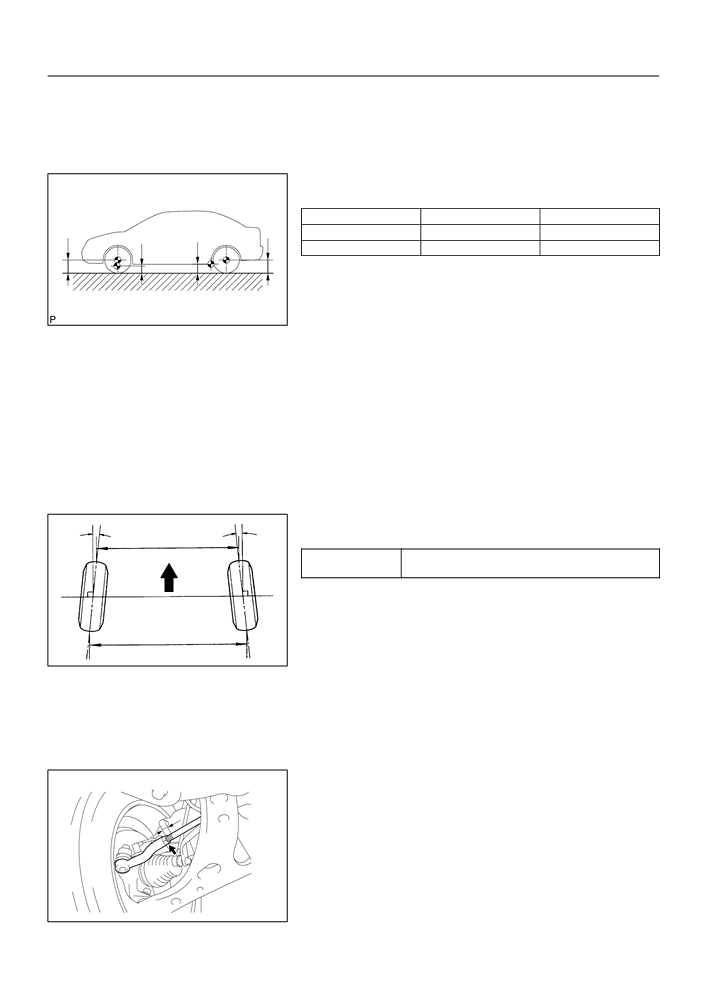

MEASURE VEHICLE HEIGHT

Vehicle height:

USA, Canada

Mexico

Front (A - B)

87 mm (3.43 in.)

72 mm (2.84 in.)

A

Rear (D - C)

43 mm (1.69 in.)

29 mm (1.14 in.)

B

C

D

Measuring points:

A: Ground clearance of front wheel center

B: Ground clearance of lower suspension arm front

C95205

bolt center

C: Ground clearance of axle beam set bolt center

D: Ground clearance of rear wheel center

NOTICE:

Before inspecting the wheel alignment, adjust the vehicle

height to the specified value.

If the vehicle height is not the specified value, try to adjust it by

pushing down on or lifting the body.

3.

INSPECT TOE-IN

A

B

D

Toe-in:

Front

Toe-in

A + B: 0° ± 12’ (0° ± 0.2°)

(total)

C - D: 0 ± 2 mm (0 ± 0.08 in.)

If the toe-in is not within the specified value, adjust it at the rack

ends.

4.

ADJUST TOE-IN

C

(a) Remove the rack boot set clips.

SA3213

(b) Loosen the tie rod end lock nuts.

(c)

Turn the right and left rack ends by an equal amount to

adjust the toe-in.

HINT:

Try to adjust the toe-in to the center of the specified value.

(d) Make sure that the lengths of the right and left rack ends

are the same.

Rack end length difference: 1.5 mm (0.059 in.) or less

(e) Torque the tie rod end lock nuts.

Torque: 74 N·m (755 kgf·cm, 55 ft·lbf)

(f)

Place the boots on the seats and install the clips.

HINT:

Make sure that the boots are not twisted.

C90321

26-6

FRONT SUSPENSION

- FRONT WHEEL ALIGNMENT

5.

INSPECT WHEEL ANGLE

A B

B A

(a) Turn the steering wheel fully and measure the turning

angle.

Front

Wheel turning angle:

USA, Canada

Mexico

37°06’ ± 2°

37°16’ ± 2°

Inside wheel

(37.10° ± 2°)

(37.27° ± 2°)

A: Inside

Outside wheel:

B: Outside

31°49’ (31.82°)

32°08’ (32.13°)

Reference

SA0028

If the right and left inside wheel angles differ from the specified

value, check the right and left rack end lengths.

6.

INSPECT CAMBER, CASTER AND STEERING AXIS

INCLINATION

Gauge

(a) Install the camber-caster-kingpin gauge or position ve-

hicle on wheel alignment tester.

Alignment

(b) Inspect the camber, caster and steering axis inclination.

Tester

Camber, caster and steering axis inclination:

USA, Canada

Mexico

Camber

-0°32’ ± 45’

-0°22’ ± 45’

(-0.53° ± 0.75°)

(-0.37° ± 0.75°)

Z03382

Right-left error

45’ (0.75°) or less

45’ (0.75°) or less

Caster

2°50’ ± 45’

2°43’ ± 45’

(2.83° ± 0.75°)

(2.72° ± 0.75°)

Right-left error

45’ (0.75°) or less

45’ (0.75°) or less

Steering axis inclination

11°21’ ± 45’

10°59’’ ± 45’

(11.35° ± 0.75°)

(10.98° ± 0.75°)

Right-left error

45’ (0.75°) or less

45’ (0.75°) or less

If the caster and steering axis inclination are not within the spe-

cified values, after the camber has been correctly adjusted, re-

check the suspension parts for damaged and/or worn out parts.

7.

ADJUST CAMBER

NOTICE:

After the camber has been adjusted, inspect the toe-in.

(a) Remove the front wheel.

(b) Remove the 2 nuts on the lower side of the shock absorb-

er assy front LH.

NOTICE:

When removing nut, stop the bolt from rotating and loosen

the nut.

(c)

Clean the installation surfaces of the shock absorber assy

front LH and the steering knuckle.

(d) Temporarily install the 2 nuts.

F13683

26-7

FRONT SUSPENSION

- FRONT WHEEL ALIGNMENT

(e) Adjust the camber by pushing or pulling the lower side of

the shock absorber in the direction in which the camber

adjustment is required.

(f)

Tighten the nuts.

Torque: 153 N m (1,560 kgf cm, 113 ft lbf)

(g) Install the front wheel.

Torque: 103 N·m (1,050 kgf·cm, 76 ft·lbf)

F13684

(h) Check the camber.

HINT:

1

F

Try to adjust the camber to the center of the specified val-

ue.

F

Adjusting value for the set bolts is -1_30’ - 0_30’ (-1.5_

- 0.5_).

2

If the camber is not within the specified value, using the follow-

ing table, estimate how much additional camber adjustment will

F13685

be required, and select the camber adjusting bolt.

Set Bolt

Adjusting Bolt

Bolt

90105-15001

90105-15004

90105-15005

90105-15006

1 Dot

2 Dots

3 Dots

Adjusting

Value

1

2

1

2

1

2

1

2

–1°30’ - -1°15’

-1°15’ - -1°00’

-1°00’ - -45’

-45’ - -30’

-30’ - -15’

-15’ - 0’

0’ - 15’

15’ - 30’

30’ - 45’

45’ - 1°00’

1°00’ - 1°15’

1°15’ - 1°30’

F12938

(i)

Perform the steps mentioned above again. At step (e), re-

place 1 or 2 selected bolts.

HINT:

When replacing the 2 bolts, replace 1 bolt at a time.

26-2

FRONT SUSPENSION

- FRONT SUSPENSION SYSTEM

2607S-01

REPAIR

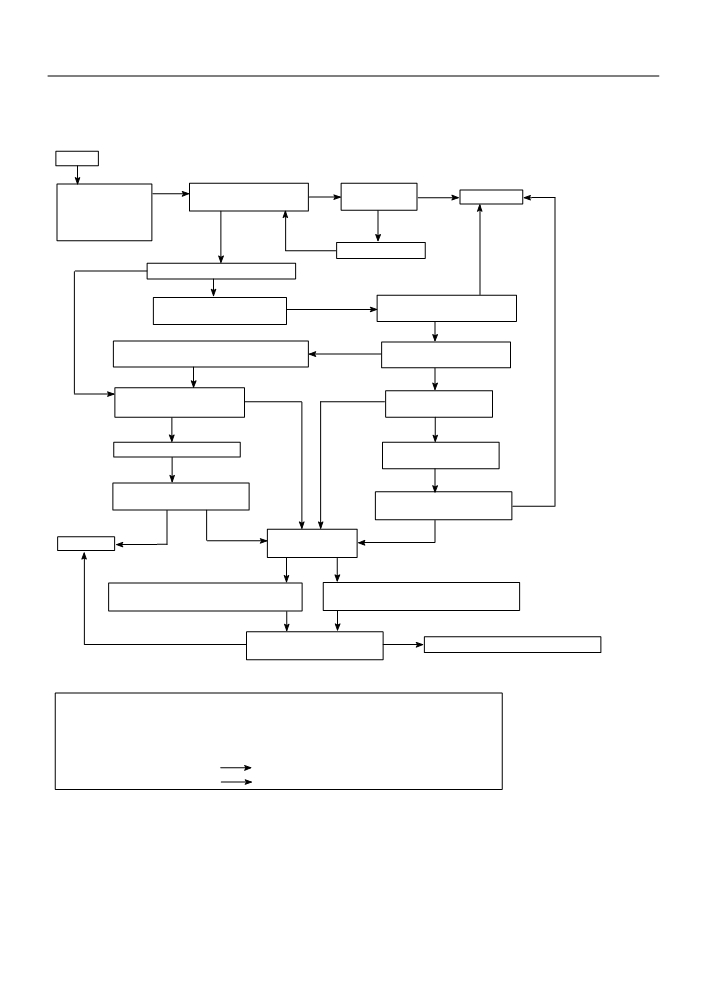

HINT:

This is a flow chart for vehicle pull.

START

Preliminary Check

ROAD TEST

NO

Is there steering

NO

*

COMPLETE

_ Tire pressure

Does the vehicle lead/pull?

off center?

_ Vehicle height

YES

YES

_ Brake dragging

Adjust front tie rods.

YES

Are the tires uni-directional type?

NO

NO

Cross switch front tire & wheel

ROAD TEST

assemblies (left & right).

Does the vehicle still lead/pull?

YES

Choose the position of front tire & wheel

YES

Does the vehicle lead/pull in

assemblies where there is least amount of pull.

same direction as before?

NO

Check front wheel alignment.

YES

NO

Is the lead/pull stronger

Is it within specification?

than before?

NO

YES

Adjust front wheel alignment.

Reverse the front left side

tire and rebalance it.

ROAD TEST

ROAD TEST

NO

Does the vehicle still lead/pull?

Does the vehicle still lead/pull?

NO

YES

YES

Does the vehicle

COMPLETE

lead/pull to the left?

NOTICE : Do not exceed 1 ° of cross camber.

YES

NO

Do not exceed adjustment range.

Increase right front camber and decrease

Increase left front camber and decrease

left front camber until lead/pull is eliminated.

right front camber until lead/pull is eliminated.

NO

ROAD TEST

YES

Contact your local retail tire distributor.

Does the vehicle still lead/pull?

Select a flat road where the vehicle can be driven in a straight line for 100 meters at a constant speed

of 35mph. Please confirm safety and set the steering wheel to its straight position. Drive the vehicle in

a straight line for 100 meters at a constant speed of 35 mph without holding the steering wheel.

(1) The vehicle can keep straight but the steering wheel has some angle.

STEERING OFF CENTER (See page 50-4)

(2) The vehicle cannot keep straight.

STEERING PULL