Subaru Legacy IV (2008 year). Service manual - part 462

FU(H6DO)-67

Fuel Delivery and Evaporation Lines

FUEL INJECTION (FUEL SYSTEMS)

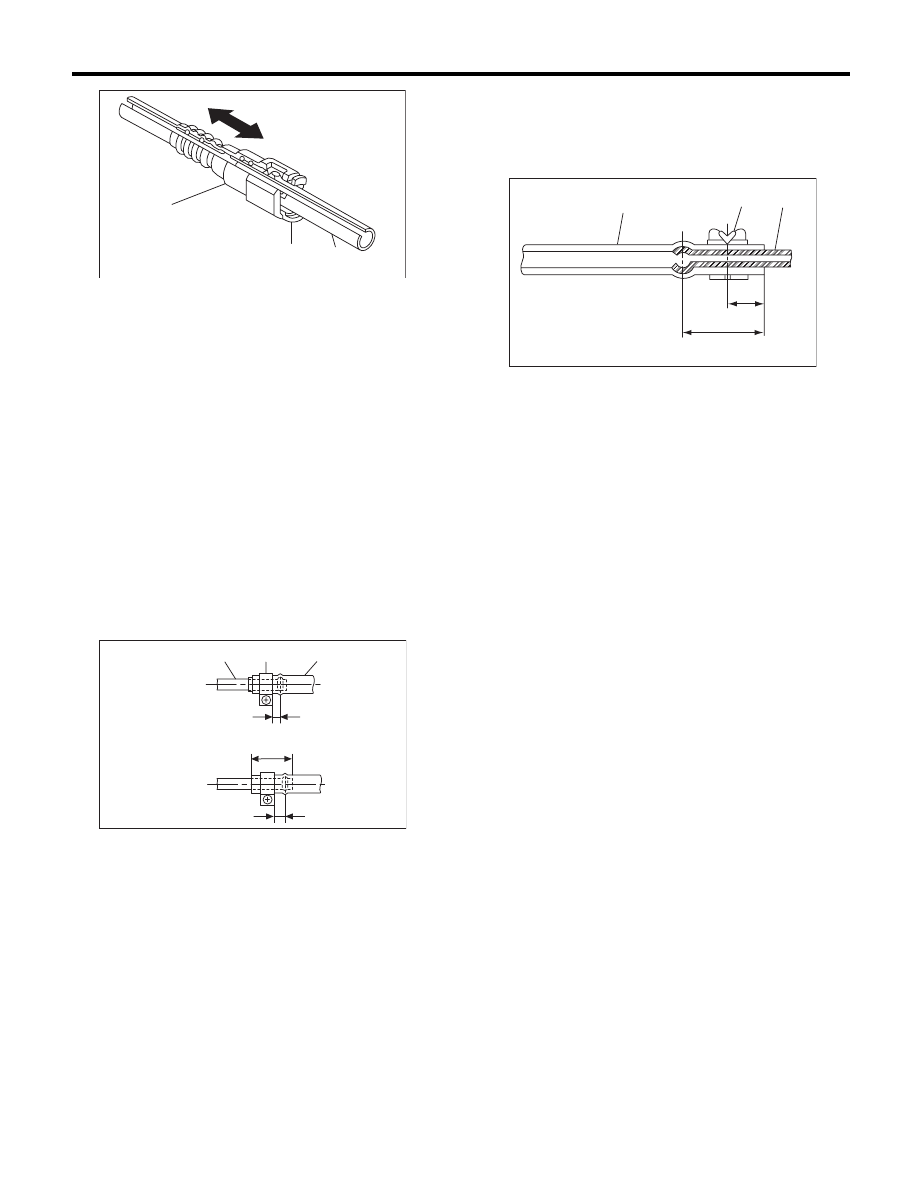

2. CONNECTING THE FUEL DELIVERY

HOSE

Connect the fuel delivery hose to the pipe with an

overlap of 20 to 25 mm (0.79 to 0.98 in).

Type A: When the amount to be inserted is speci-

fied.

Type B: When the amount to be inserted is not

specified.

L1: 2.5

r

1.5 mm (0.098

r

0.059 in)

L2: 22.5

r

2.5 mm (0.886

r

0.098 in)

CAUTION:

Be sure to inspect hoses and their connections

for any leakage of fuel.

3. CONNECTING THE EVAPORATION HOSE

Connect the evaporation hose to the pipe with an

overlap of 15 to 20 mm (0.59 to 0.79 in).

L = 17.5

r

2.5 mm (0.689

r

0.098 in)

C: INSPECTION

1) Make sure that there are no cracks on the fuel

pipes and fuel hoses.

2) Make sure the fuel pipe and fuel hose connec-

tions are tightened firmly.

(A) Connector

(B) Retainer

(C) Pipe

(1) Type A

(2) Type B

(3) Pipe

(4) Clamp

(5) Hose

FU-00127

( A )

( B )

( C )

FU-03390

(3)

(4)

(5)

L2

(1)

(2)

L1

L1

(1) Hose

(2) Clip

(3) Pipe

FU-00129

(1)

(2)

L/2

L

(3)