Subaru Legacy IV (2008 year). Service manual - part 27

PM-48

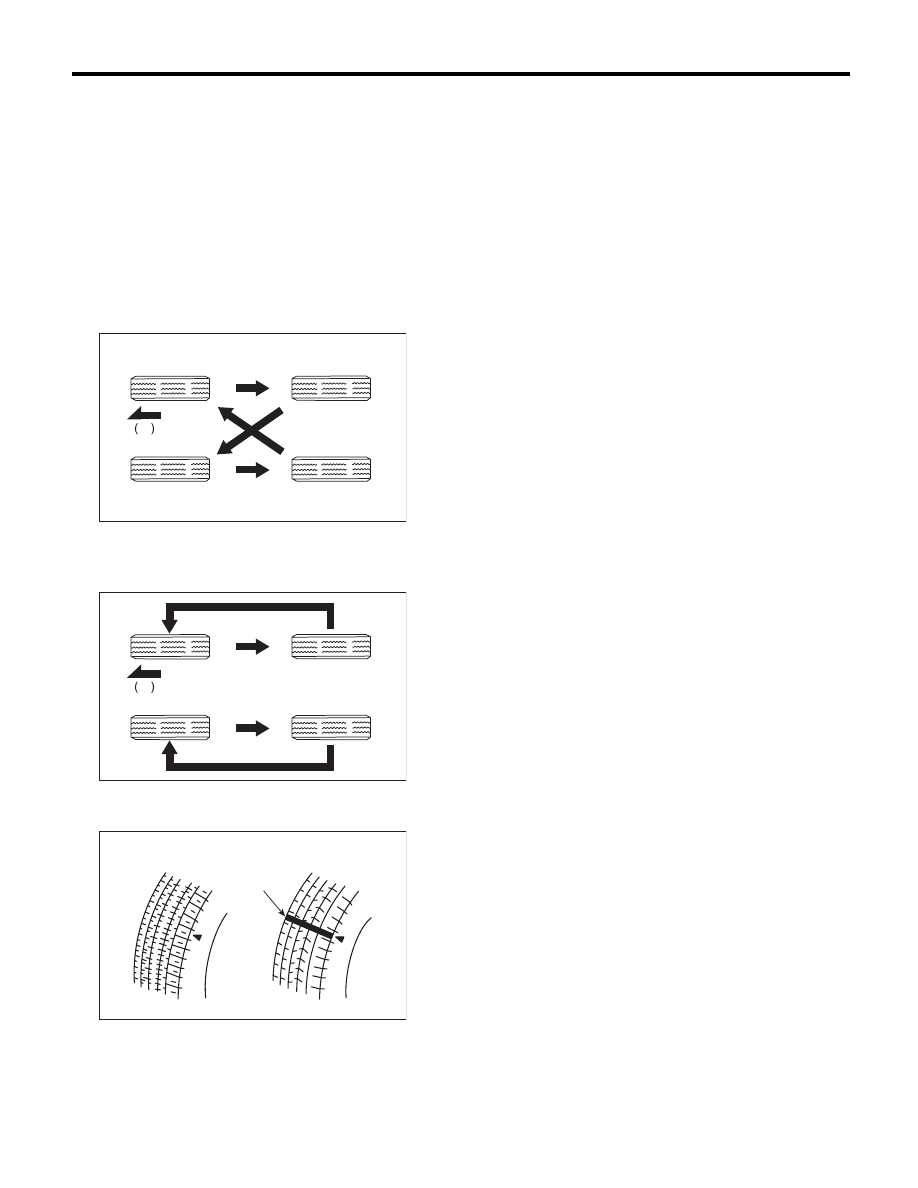

Tire Rotation

PERIODIC MAINTENANCE SERVICES

23.Tire Rotation

A: INSPECTION

1) When the tread has worn down to less than 1.6

mm (0.063 in) or the wear indicator appears across

the tread, replace the tire. (Replace the right and

left tire as a set.)

2) If the tire appears to be worn unevenly, adjust

the wheel alignment.

3) Next, make a tire rotation between front and rear

as shown in the figure, make sure tires are worn

evenly.

• When the direction of tire rotation is not specified

• When the direction of tire rotation is specified

4) Re-register the transmitter ID when rotation was

performed. (3.0 L U4 model) <Ref. to TPM(diag)-

10, REGISTER TRANSMITTER ID, OPERATION,

Subaru Select Monitor.>

(1) Front

(1) Front

(A) New tread

(B) Damaged tread

(C) Tread wear indicator

WT-00113

1

WT-00115

1

PM-00080

(A)

(B)

(C)